Method for preparing low-resistance titanium nitride film through low-temperature magnetron sputtering

A technology of magnetron sputtering and titanium nitride, which is applied in sputtering plating, ion implantation plating, metal material coating technology, etc., can solve the problems of low resistivity and complicated process, and achieve low resistivity and process Simplicity, good uniformity and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

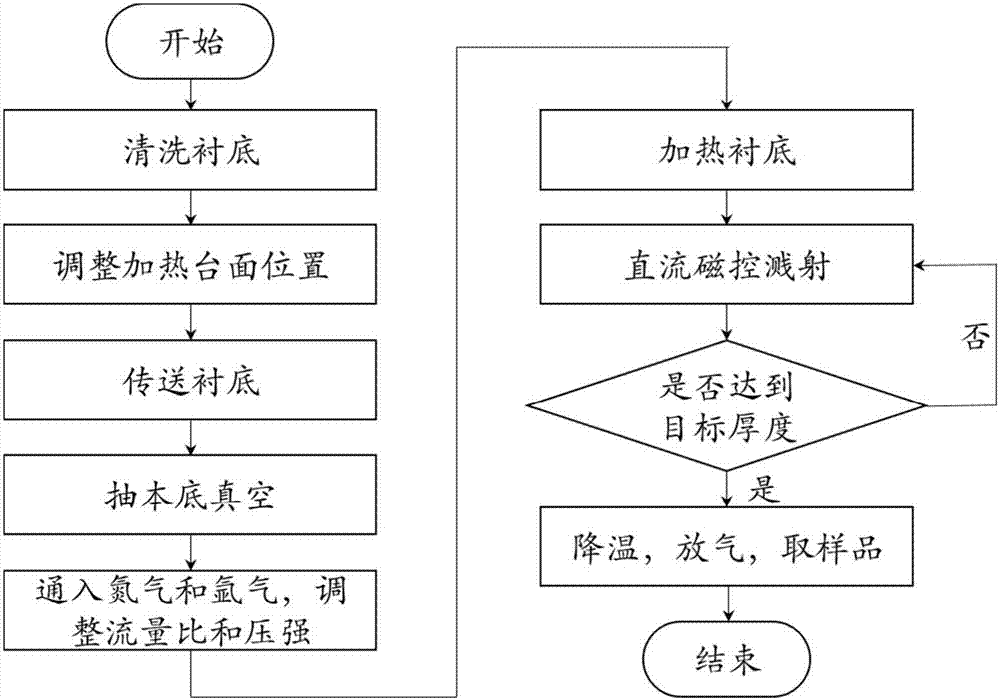

Method used

Image

Examples

Embodiment 1

[0027] The magnetron sputtering coating machine in this embodiment adopts the three-target ultra-vacuum magnetron sputtering coating equipment developed by Shenyang Judong Vacuum Technology Research Institute.

[0028] 1) Install a titanium target with a purity of 99.999% at the target head of the three-target ultra-vacuum magnetron sputtering coating equipment. The target material is a cylinder with a diameter of 76 mm and a thickness of 5 mm. Adjust the positions of the heating table and the titanium target so that Keep it at 15cm.

[0029] 2) RCA standard cleaning single-polished two-inch silicon wafers, using the whole silicon wafer or a 15mm×15mm silicon wafer obtained by dicing as the substrate;

[0030] 3) Put the silicon substrate into the heating table of the magnetron sputtering chamber, adjust the heating table so that the distance between the substrate and the titanium target is kept at 15 cm, and the polished surface of the silicon wafer faces the titanium target;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com