Processing technology of Liupao tea

A processing technology, Liubao tea technology, applied in the field of tea preparation, can solve the problems of increasing the technical difficulty of pesticide residues in tea, destroying the quality of tea, affecting the aroma of tea, and the aftertaste of taste, so as to shorten the boring time, promote conversion, and shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

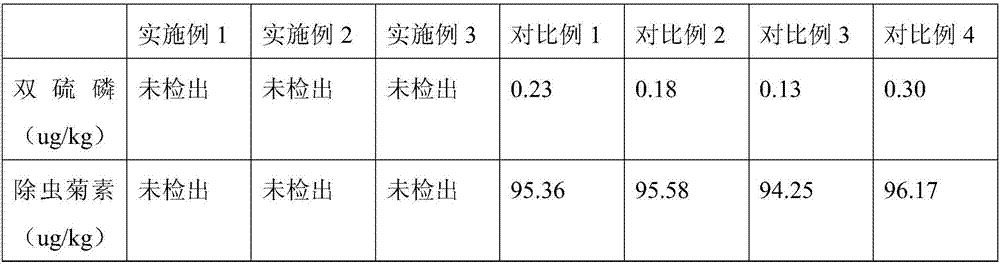

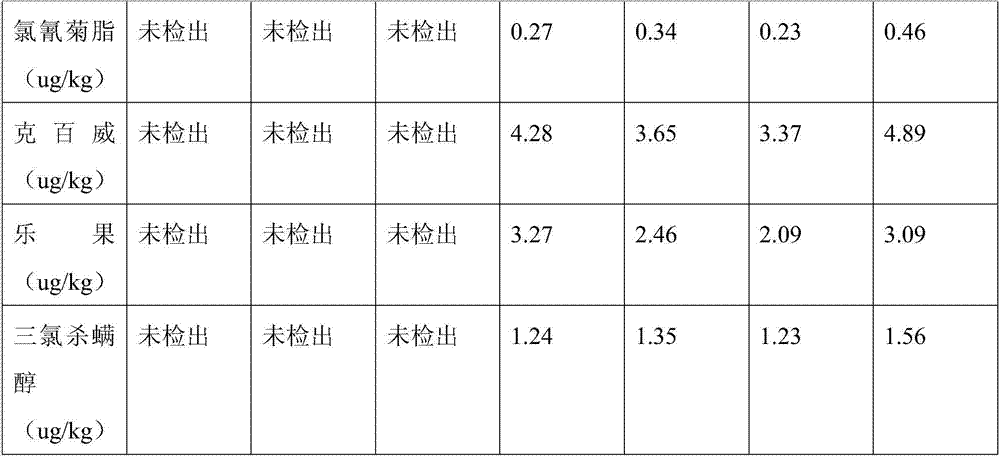

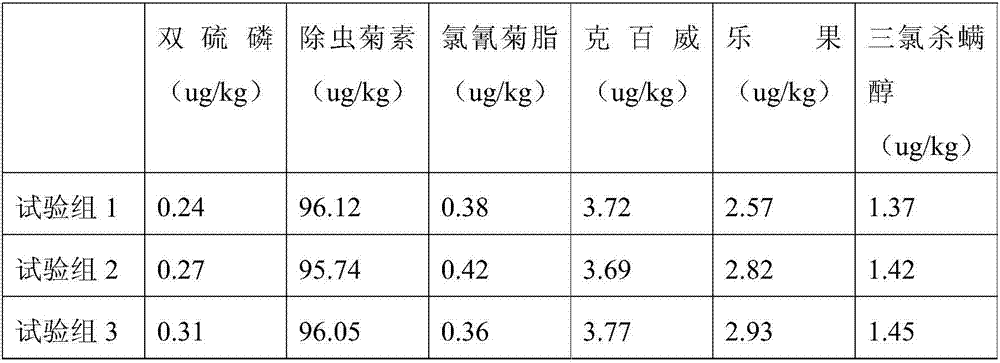

Examples

Embodiment 1

[0036] A Liubao tea processing technology, comprising the steps of:

[0037] Raw material pretreatment: put the freshly picked tea leaves in a cleaning tank with an ultraviolet lamp with a wavelength of 254nm on the inner wall, and spray ZnO / TiO into the cleaning tank 2 Composite nano-photocatalytic materials, and feed 1200mg / h of oxygen into the cleaning pool, make the tea leaves roll and wash in water for 3 minutes, wash them again with pure water, and drain the water droplets on the surface of the tea leaves;

[0038] Finishing: Put the tea leaves without water droplets on the surface in a finishing machine, and fix them at a temperature of 50°C for 1 minute;

[0039] Initial kneading: Knead the finished tea leaves with a kneading machine to make the tea leaves form strands;

[0040] Dull heap: Spray a mixture of Aspergillus fumigatus, Escherichia and Bacillus subtilis with an effective bacterial species ratio of 1:5:1 at a concentration of 1×10 8 After degrading the micr...

Embodiment 2

[0052] A Liubao tea processing technology, comprising the steps of:

[0053] Raw material pretreatment: put the freshly picked tea leaves in a cleaning tank with an ultraviolet lamp with a wavelength of 365nm on the inner wall, and spray ZnO / TiO into the cleaning tank 2 Composite nano-photocatalytic materials, and feed 1000 mg / h of oxygen into the cleaning pool, make the tea leaves roll and wash in water for 5 minutes, wash them again with pure water, and drain the water drops on the tea leaves; among them, ZnO / TiO 2 The composite nano photocatalytic material is placed in the nanoporous cortical structure PVDF hollow fiber membrane fixed in the cleaning pool;

[0054] Fixing: put the tea leaves without water droplets on the surface in the fixing machine, and fix them at a temperature of 40°C for 2 minutes;

[0055] Initial kneading: Knead the finished tea leaves with a kneading machine to make the tea leaves form strands;

[0056] Dull heap: Spray a mixture of Aspergillus fu...

Embodiment 3

[0068] A Liubao tea processing technology, comprising the steps of:

[0069] Raw material pretreatment: put the freshly picked tea leaves in a cleaning tank with an ultraviolet lamp with a wavelength of 254nm on the inner wall, and spray ZnO / TiO into the cleaning tank 2 Composite nano-photocatalytic materials, and feed 1100mg / h of oxygen into the cleaning pool, make the tea leaves roll and wash in water for 4 minutes, wash with pure water again, and drain the water droplets on the surface of the tea leaves; among them, ZnO / TiO 2 The composite nano photocatalytic material is placed in the nanoporous cortical structure PVDF hollow fiber membrane fixed in the cleaning pool;

[0070] Finishing: Put the tea leaves without water droplets on the surface in a finishing machine, and fix them at a temperature of 45°C for 2 minutes;

[0071] Initial kneading: Knead the finished tea leaves with a kneading machine to make the tea leaves form strands;

[0072] Dull heap: Spray a mixture o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com