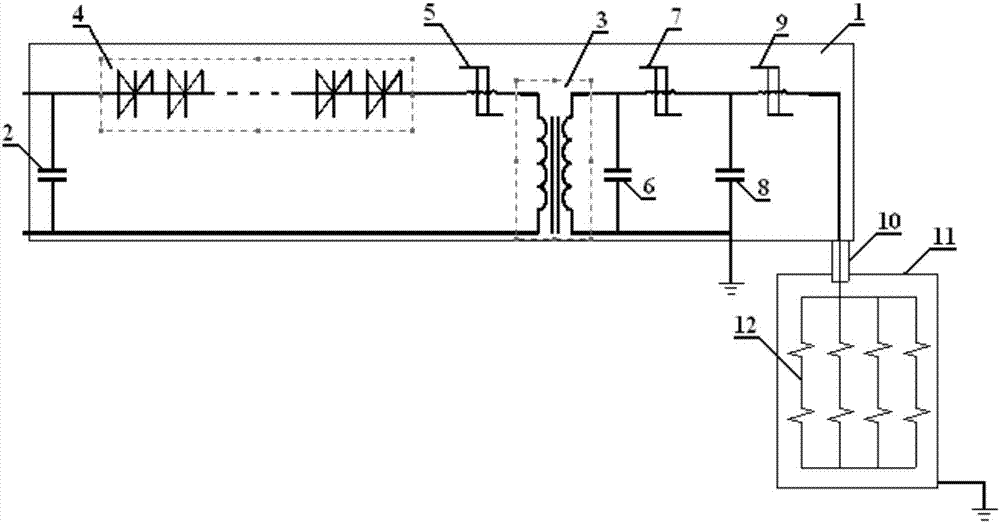

Pulse generation device used for flue gas purification

A technology of pulse generating device and pulse transformer, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., and can solve problems such as high energy consumption, restricted development, and low plasma efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The pulse generating device for flue gas purification described in the above technical solution is adopted, wherein the series high-voltage switch group (4) is formed by connecting 10 reverse conduction transistors in series, and the working voltage of each reverse conduction transistor is 1KV. The working voltage of the high-voltage switch group (4) is 10KV; the design capacitance of the energy storage capacitor (2) is 2μF, the rated withstand voltage is 16KV, and the stored energy is 100J under the design working voltage of 10KV;

[0074] The design transformation ratio of the pulse transformer (3) is 10, the design output voltage is 100KV, and the leakage inductance of the pulse transformer (3) is required to be 5 μH; the saturation inductance of the first magnetic switch (5) is 3 μH, and the connection inductance is less than 2 μH, so that the pulse The output pulse rise time of the transformer (3) is about 10 μs;

[0075] The pulse transformer (3) outputs a pulse w...

Embodiment 2

[0079] The pulse generating device for flue gas purification described in the above technical solution is adopted, wherein the series high-voltage switch group (4) is formed by series connection of 8 reverse conduction transistors, and the working voltage of each reverse conduction transistor is 1KV. The working voltage of the high-voltage switch group (4) is 8KV; the design capacitance of the energy storage capacitor (2) is 2μF, the rated withstand voltage is 16KV, and the stored energy is 64J under the design working voltage of 8KV;

[0080] The design transformation ratio of the pulse transformer (3) is 10, the design output voltage is 80KV, and the leakage inductance of the pulse transformer (3) is required to be 5 μH; the saturation inductance of the first magnetic switch (5) is 3 μH, and the inductance of the connection line is less than 2 μH, so that the pulse The output pulse rise time of the transformer (3) is about 10 μs;

[0081] The pulse transformer (3) outputs a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com