Method for removing azo dye mixed pollutant wastewater through bio-electrochemical reactor system

A bioelectrochemical and reactor system technology is applied in the treatment field of azo dye mixed polluted wastewater, which can solve the problems of low efficiency, slow treatment speed, high cost of physical and chemical methods, and achieve high efficiency, rapid reduction and mineralization, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: The method for removing azo dye mixed polluted wastewater by using electric stimulation anaerobic-aerobic continuous flow reaction device in this embodiment is carried out according to the following steps:

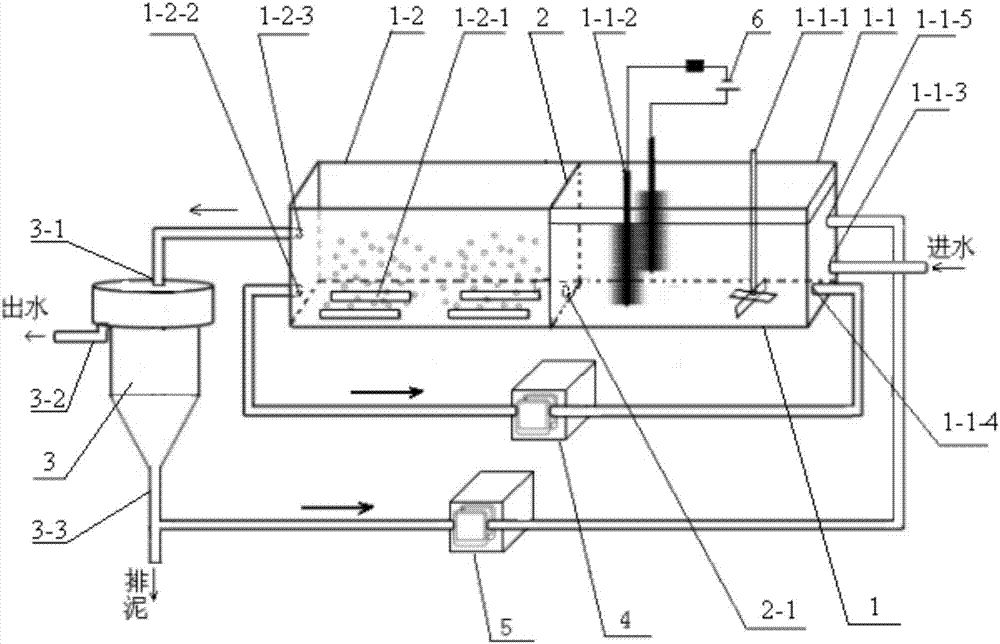

[0026] 1. Construction of the bioelectrochemical reactor system: The bioelectrochemical reactor system consists of a reactor shell 1, a partition 2, a secondary sedimentation tank 3, a first reflux pump 4, a second reflux pump 5 and an adjustable DC power supply 6 Composition; the clapboard 2 divides the shell 1 into an anaerobic pool 1-1 and an aerobic pool 1-2; the lower part of the clapboard 2 has a water hole 2-1; an agitator 1-1 is arranged in the anaerobic pool 1-1 1-1 and a pair of electrodes 1-1-2; the electrodes 1-1-2 are connected to the adjustable DC power supply 6; the lower end of the side wall of the anaerobic tank 1-1 is provided with a water inlet 1-1-3 and nitrifying liquid Return port 1-1-4, sludge return port 1-1-5 at the ...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step two a, the vitamin solution is composed of vitamin H 2.0mg, folic acid 2.0mg, pyridoxine hydrochloride 10.0mg, thiamine 5.0mg, riboflavin 5.0 mg of niacin, 5.0 mg of nicotinic acid, 5.0 mg of calcium D-pantothenate, 0.1 mg of vitamin B12, 5.0 mg of p-aminobenzoic acid, 5.0 mg of lipoic acid and 1L of distilled water; the others are the same as in Embodiment 1.

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mineral element liquid is made of nitrilotriacetic acid 1.5g, MgSO 4 ·7H 2 O 3.0g, MnSO 4 ·H 2 O 0.5g, NaCl 1.0g, FeSO 4 ·7H 2 O0.1g, CoCl 2 ·6H 2 O 0.1g, CaCl2 0.1g, ZnSO 4 ·7H 2 O 0.1g, CuSO 4 ·5H 2 O 0.01g, AlK(SO 4 ) 2 12H 2 O 0.01g, H 3 BO 3 0.01g, Na 2 MoO 4 2H 2 The solution that O 0.01g and 1L distilled water are mixed; Others are identical with specific embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com