A heavy metal wastewater treatment agent

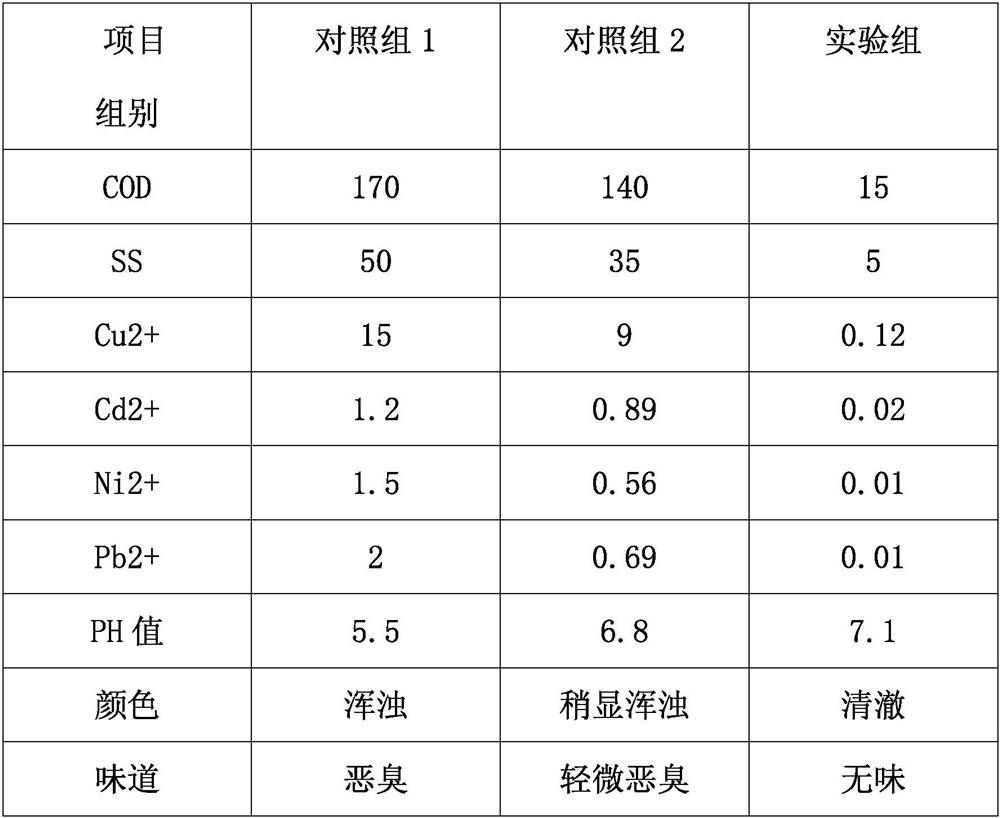

A wastewater treatment agent and heavy metal technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem that the heavy metal ion content in wastewater cannot be effectively reduced, water cannot be reused, and the cost of wastewater treatment It can reduce the content of heavy metal ions, the production method is simple, and the decolorization effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A heavy metal wastewater treatment agent, comprising the following raw materials in parts by weight: 15 parts of sodium carboxymethyl cellulose, 11 parts of sodium cumene sulfonate, 17 parts of fly ash, 4 parts of carrageenan, 8 parts of ferrous sulfate, silicon 9 parts of algae earth, 12 parts of polyphosphorus ferric chloride, 9 parts of calcium chloride, 2 parts of chitosan, 3 parts of Trichoderma konii, 2 parts of ammonium persulfate, 3 parts of sodium diacetate, 6 parts of peracetic acid, 11 parts of ethanol, 7 parts of calcium-based bentonite and 18 parts of water.

[0021] A preparation method of a heavy metal wastewater treatment agent, mainly comprising the following steps:

[0022] 1) Take 15 parts of sodium carboxymethyl cellulose, 17 parts of fly ash and 7 parts of calcium-based bentonite and mix them thoroughly, put them into a muffle furnace, dry them at 100°C for 4 hours, and then adjust the temperature to 710°C Calcined for 1h to obtain a calcined mixtu...

Embodiment 2

[0029] A heavy metal wastewater treatment agent, comprising the following raw materials in parts by weight: 13 parts of sodium carboxymethyl cellulose, 13 parts of sodium cumene sulfonate, 19 parts of fly ash, 6 parts of carrageenan, 10 parts of ferrous sulfate, silicon 11 parts of algae earth, 14 parts of polyphosphorus ferric chloride, 11 parts of calcium chloride, 4 parts of chitosan, 5 parts of Trichoderma konii, 4 parts of ammonium persulfate, 5 parts of sodium diacetate, 8 parts of peracetic acid, 13 parts of ethanol, 9 parts of calcium-based bentonite and 20 parts of water.

[0030] A preparation method of a heavy metal wastewater treatment agent, mainly comprising the following steps:

[0031] 1) Take 13 parts of sodium carboxymethyl cellulose, 19 parts of fly ash and 9 parts of calcium-based bentonite and mix them thoroughly, put them into a muffle furnace, dry them at 150°C for 4 hours, and then adjust the temperature to 750°C Calcined for 1.5h to obtain a calcined ...

Embodiment 3

[0038] A heavy metal wastewater treatment agent, comprising the following raw materials in parts by weight: 14 parts of sodium carboxymethyl cellulose, 12 parts of sodium cumene sulfonate, 18 parts of fly ash, 5 parts of carrageenan, 9 parts of ferrous sulfate, silicon 10 parts of algae earth, 13 parts of polyphosphorus ferric chloride, 10 parts of calcium chloride, 3 parts of chitosan, 4 parts of Trichoderma konii, 3 parts of ammonium persulfate, 4 parts of sodium diacetate, 7 parts of peracetic acid, 12 parts of ethanol, 8 parts of calcium-based bentonite and 19 parts of water.

[0039] A preparation method of a heavy metal wastewater treatment agent, mainly comprising the following steps:

[0040]1) Take 14 parts of sodium carboxymethyl cellulose, 18 parts of fly ash and 8 parts of calcium-based bentonite and mix them thoroughly, put them into a muffle furnace, dry them at 130°C for 4 hours, and then adjust the temperature to 730°C Calcined for 1.2h to obtain a calcined mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com