Cotton planting slow release fertilizer

A slow-release fertilizer and cotton technology, applied in the direction of nitrogen fertilizer, potassium fertilizer, magnesium fertilizer, etc., can solve the problems of poor soil physical and chemical properties, increase the economic burden of farmers, and waste resources, etc., to extend the effective release period, avoid premature aging and defertilization , Improve the effect of yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

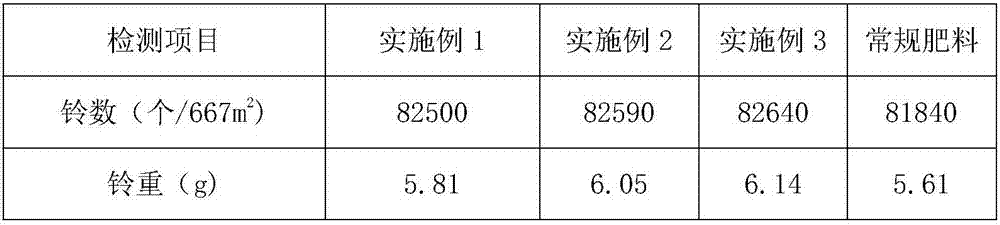

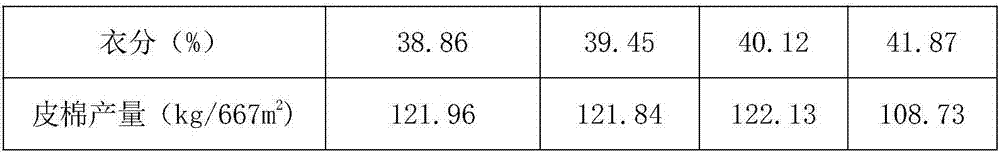

Embodiment 1

[0030] A slow-release fertilizer for cotton planting, comprising inner layer slow-release fertilizer particles and outer layer slow-release fertilizer coating; it is characterized in that the inner layer slow-release fertilizer particles include the following raw materials: urea 20 grams, potassium chloride 10 grams, chloride 10 grams of ammonium, 10 grams of ammonium sulfate, 10 grams of general calcium, 5 grams of zinc sulfate, 10 grams of mixed phosphate fertilizer, 4 grams of bentonite, 2 grams of bauxite powder, 5 grams of borax, 2 grams of zinc humate, 2 grams of boron humate , 1 gram of calcium humate, 1 gram of magnesium humate and 1 gram of sodium nitrophenolate;

[0031] The outer slow-release fertilizer coating includes the following raw materials: 10 grams of lecithin, 5 grams of amidinothiourea, 5 grams of N-methylolacrylamide, 10 grams of unsaturated polyester resin, 4 grams of cyclohexanol, 2-butyl 5 grams of alcohol, 1 gram of talc, 1 gram of kaolin, 1 gram of ...

Embodiment 2

[0044] A slow-release fertilizer for cotton planting, comprising inner layer slow-release fertilizer particles and outer layer slow-release fertilizer coating; it is characterized in that the inner layer slow-release fertilizer particles include the following raw materials: urea 30 grams, potassium chloride 20 grams, chloride 20 grams of ammonium, 25 grams of ammonium sulfate, 20 grams of general calcium, 10 grams of zinc sulfate, 30 parts of mixed phosphate fertilizer, 7 grams of bentonite, 4 grams of bauxite powder, 10 grams of borax, 10 grams of zinc humate, 8 grams of boron humate , 5 grams of calcium humate, 4 grams of magnesium humate and 2 grams of sodium nitrophenolate;

[0045] The outer slow-release fertilizer coating includes the following raw materials: 20 grams of lecithin, 10 grams of amidinothiourea, 15 grams of N-methylolacrylamide, 30 grams of unsaturated polyester resin, 10 grams of cyclohexanol, 2-butyl 13 grams of alcohol, 5 grams of talc, 4 grams of kaolin...

Embodiment 3

[0058] A slow-release fertilizer for cotton planting, comprising an inner layer slow-release fertilizer granule and an outer layer slow-release fertilizer coating; it is characterized in that the inner layer slow-release fertilizer granule includes the following raw materials: urea 25 grams, potassium chloride 15 grams, chloride 15 grams of ammonium, 15 grams of ammonium sulfate, 15 grams of general calcium, 8 grams of zinc sulfate, 20 parts of mixed phosphate fertilizer, 6 grams of bentonite, 3 grams of bauxite powder, 8 grams of borax, 5 grams of zinc humate, 5 grams of boron humate , 3 grams of calcium humate, 3 grams of magnesium humate and 1 gram of sodium nitrophenolate;

[0059] The outer slow-release fertilizer coating includes the following raw materials: 15 grams of lecithin, 8 grams of amidinothiourea, 10 grams of N-methylolacrylamide, 20 grams of unsaturated polyester resin, 8 grams of cyclohexanol, 2-butyl 9 grams of alcohol, 3 grams of talc, 3 grams of kaolin, 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com