Preparation method of corrosion-resistant anti-electromagnetic radiation fabric

An anti-electromagnetic radiation and corrosion-resistant technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of poor corrosion resistance, poor bonding fastness, affecting the softness of fabrics, etc., to improve bonding performance, density Small, the effect of improving the electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

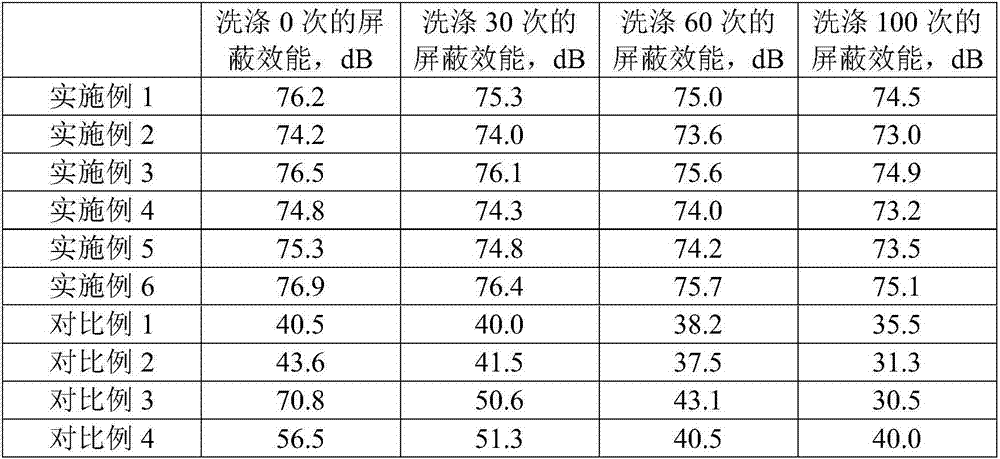

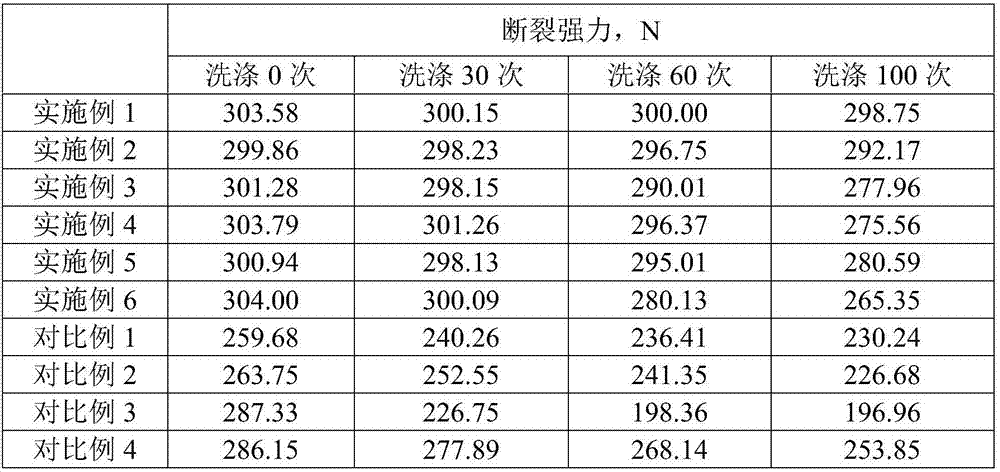

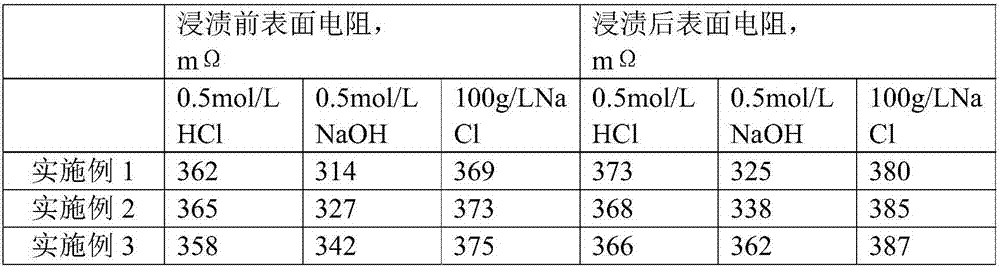

Examples

Embodiment 1

[0026] A preparation method of a corrosion-resistant anti-electromagnetic radiation fabric, comprising the following steps:

[0027] (1) Prepare an aqueous solution of camphorsulfonic acid with a concentration of 0.5mol / L, and divide it into two parts of equal volume; mix the aniline monomer and copper powder, let it stand for 20 minutes, add it to one of the above-mentioned camphorsulfonic acid solutions, and stir Mix the oxidant and another part of camphorsulfonic acid solution uniformly to obtain the mixture 1 after uniformity, and prepare the mixed solution 2. Slowly drop the mixed solution 2 into the mixed solution 1 at -10°C, and react for 1 hour. After the reaction is completed, , washed with deionized hydrated absolute ethanol, and dried to obtain a copper powder-doped polyaniline electromagnetic shielding material;

[0028] Wherein, the content of copper powder in the combined solution 1 is 0.005g / mL; the mass ratio of copper powder to aniline monomer is 0.25:1; the o...

Embodiment 2

[0033] A preparation method of a corrosion-resistant anti-electromagnetic radiation fabric, comprising the following steps:

[0034] (1) Prepare an aqueous solution of camphorsulfonic acid with a concentration of 2mol / L, and divide it into two parts of equal volume; mix the aniline monomer and copper powder, let it stand for 40 minutes, add it to one of the above-mentioned camphorsulfonic acid solutions, and stir evenly Finally, the mixture 1 is obtained, and the oxidant and another part of the camphorsulfonic acid solution are mixed uniformly to prepare the mixed solution 2. At 0°C, the mixed solution 2 is slowly dropped into the mixed solution 1, and reacted for 6 hours. After the reaction, use Washing with deionized hydration absolute ethanol, and drying to prepare copper powder-doped polyaniline electromagnetic shielding material;

[0035] Among them, the content of copper powder in the combined solution 1 is 0.1g / mL; the mass ratio of copper powder to aniline monomer is 2...

Embodiment 3

[0040] A preparation method of a corrosion-resistant anti-electromagnetic radiation fabric, comprising the following steps:

[0041](1) Prepare an aqueous solution of camphorsulfonic acid with a concentration of 1mol / L, and divide it into two parts of equal volume; mix the aniline monomer and copper powder, let it stand for 25 minutes, then add it to one of the above-mentioned camphorsulfonic acid solutions, and stir evenly After the mixture 1 is obtained, mix the oxidant and another part of the camphorsulfonic acid solution evenly to prepare the mixed solution 2, slowly drop the mixed solution 2 into the mixed solution 1 at -15°C, and react for 2 hours. After the reaction, Washing with deionized hydrated absolute ethanol and drying to prepare copper powder-doped polyaniline electromagnetic shielding material;

[0042] Among them, the content of copper powder in the combined solution 1 is 0.01g / mL; the mass ratio of copper powder to aniline monomer is 0.5:1; the oxidizing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com