Preparation method for high-flux non-continuous dehumidified micropattern substrate

A discontinuous, high-throughput technology, applied in the field of analysis and detection, it can solve the problems of poor dispersion of metal particles, unavoidable introduction of impurities, and difficult to control growth behavior, achieving reusable, good Raman signal, Guaranteed reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

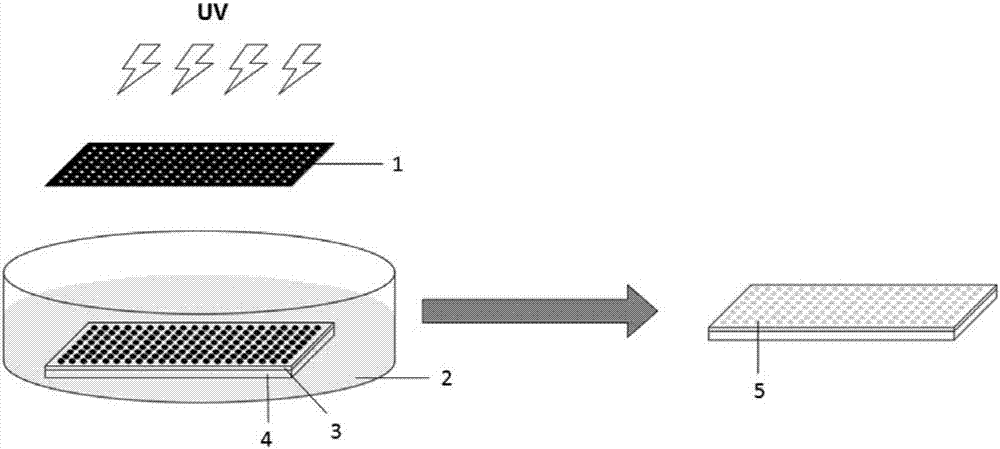

[0036] 1. Preparation of titanium dioxide substrate: Dilute the titanium dioxide aqueous dispersion to a concentration of 5wt%; perform plasma hydrophilic treatment on a clean quartz sheet or high borosilicate heat-resistant glass; add an appropriate amount of titanium dioxide colloidal aqueous solution dropwise to the hydrophilic treated Spin-coat at 3000rpm for 0.5min on the glass slide substrate. After the spin coating is completed, it is dried and calcined at 450° C. for 1 hour to obtain a titanium dioxide substrate.

[0037] 2. Hydrophobic treatment of the titanium dioxide substrate: dilute perfluorodecyltriethoxysilane in n-hexane to form a hydrophobic solution with a concentration of 1 vol%. Take an appropriate amount of the above-mentioned hydrophobic solution in a clean vessel, place it together with the titanium dioxide substrate in a relatively closed space, and heat at 100°C for 12h. After heating, the hydrophobically treated titanium dioxide substrate was washed ...

Embodiment 2

[0040] 1. Preparation of titanium dioxide substrate: Dilute the titanium dioxide aqueous dispersion to a concentration of 10wt%; soak a clean quartz sheet or high borosilicate heat-resistant glass in piranha solution for hydrophilic treatment, wherein the formula of piranha solution is concentrated sulfuric acid: 30 % hydrogen peroxide = 3:1 (volume ratio); drop an appropriate amount of titanium dioxide colloidal aqueous solution onto the glass slide substrate after hydrophilic treatment, and spin-coat at 5000 rpm for 0.1 min. After the spin coating is completed, it is dried and calcined at 450° C. for 2 hours to obtain a titanium dioxide substrate.

[0041] 2. Hydrophobic treatment of the titanium dioxide substrate: dilute perfluorodecyltriethoxysilane in n-hexane to form a hydrophobic solution with a concentration of 0.2 vol%. Take an appropriate amount of the above-mentioned hydrophobic solution in a clean vessel, place it together with the titanium dioxide substrate in a r...

Embodiment 3

[0044] 1. Preparation of titanium dioxide substrate: Dilute the titanium dioxide aqueous dispersion to a concentration of 1wt%; perform plasma hydrophilic treatment on a clean quartz sheet or high borosilicate heat-resistant glass; add an appropriate amount of titanium dioxide colloidal aqueous solution dropwise to the hydrophilic treated Spin-coat at 1000 rpm for 1 min on a glass slide substrate. After the spin coating is completed, it is dried and calcined at 500° C. for 2 hours to obtain a titanium dioxide substrate.

[0045] 2. Hydrophobic treatment of the titanium dioxide substrate: octadecyltrimethoxysilane was diluted in absolute ethanol to prepare a solution with a concentration of 0.2 vol%, to obtain a hydrophobic treatment solution. Take an appropriate amount of the above-mentioned hydrophobic treatment solution in a clean vessel, place it together with the titanium dioxide substrate in a relatively closed space, and heat at 50° C. for 12 hours. After heating, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com