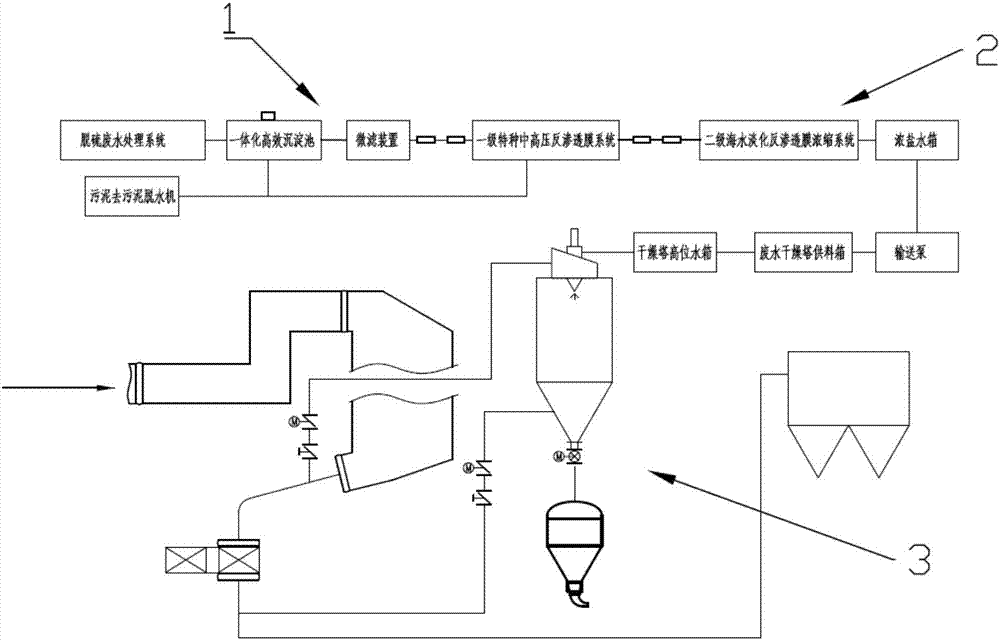

Zero emission system device for desulfurization wastewater evaporated by drying tower after concentration

A desulfurization wastewater and system device technology, which is applied in general water supply saving, gaseous effluent wastewater treatment, multi-stage water treatment, etc., can solve the problems of high investment and operation costs of evaporation and crystallization, fouling of flue and electric bag filter, host Reduce the risk of fouling, reduce energy consumption, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

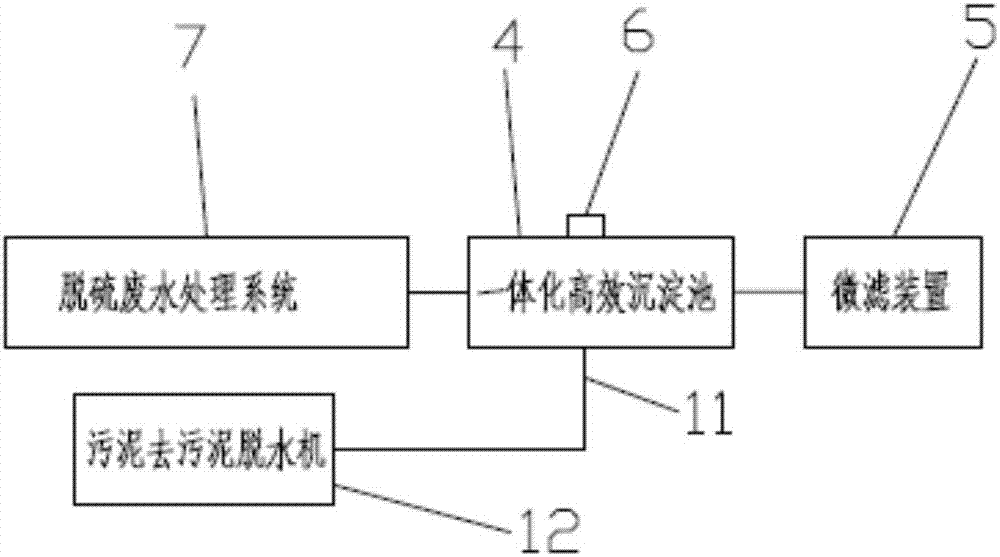

[0036] Specific embodiments: the device is specifically applied to a certain power plant, and specifically has the following parameters:

[0037] 1. The effluent water quality after treatment by the traditional wastewater system of the power plant is shown in Table 1 below:

[0038] Table 1

[0039]

[0040]

[0041] Power supply: 380V

[0042] Air source: instrument compressed air 0.6-0.8MPa

[0043] Water source: industrial water 0.5MPa

[0044] 2. The technical parameters of the drying tower evaporation system are shown in Table 2 below:

[0045] Table 2

[0046]

[0047]

[0048] 3. The main equipment list of the program is shown in Table 3 below:

[0049] table 3

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com