Ultra-high-performance concrete reinforced hollow slab bridge structure and reinforcement method thereof

A technology of concrete reinforcement and hollow slab girder, applied in the direction of bridge reinforcement, bridges, bridge parts, etc., can solve the problems of constant traffic, damage of hinge joints, long repair time, etc., to reduce the impact of traffic, good construction performance, adhesion Good junction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example is the preparation process of the ultra-high performance concrete used in the present invention.

[0037] Concrete per cubic meter is composed of the following raw materials: cement 800-1200kg, mineral admixture 50-200kg, fine aggregate 800-1200kg, steel fiber 78-300kg, water reducer (solid content) 3-15kg, defoamer 0.6-5kg, expansion agent 60-120kg, water 105-250kg.

[0038] In a specific operation process, each cubic ultra-high performance concrete includes the following raw materials and quality: 950kg of Portland cement with a strength grade above 42.5; active SiO2 100kg; CaO 38kg; SO3 44.4kg; Al2O3 7.6kg; river sand 500kg; limestone Aggregate 200kg; slag fine aggregate 400kg; steel fiber 175kg; polycarboxylate superplasticizer 8kg; nonionic surfactant 3.5kg; magnesium oxide expansion agent 75kg; water 200kg.

[0039] Among them, the length of the steel fiber is 15-20 mm, the diameter is 0.15-0.25 mm, and the particle size of the river sand, limestone ...

Embodiment 2

[0043] This embodiment is a hollow slab girder bridge structure reinforced by the ultra-high performance concrete described in Embodiment 1.

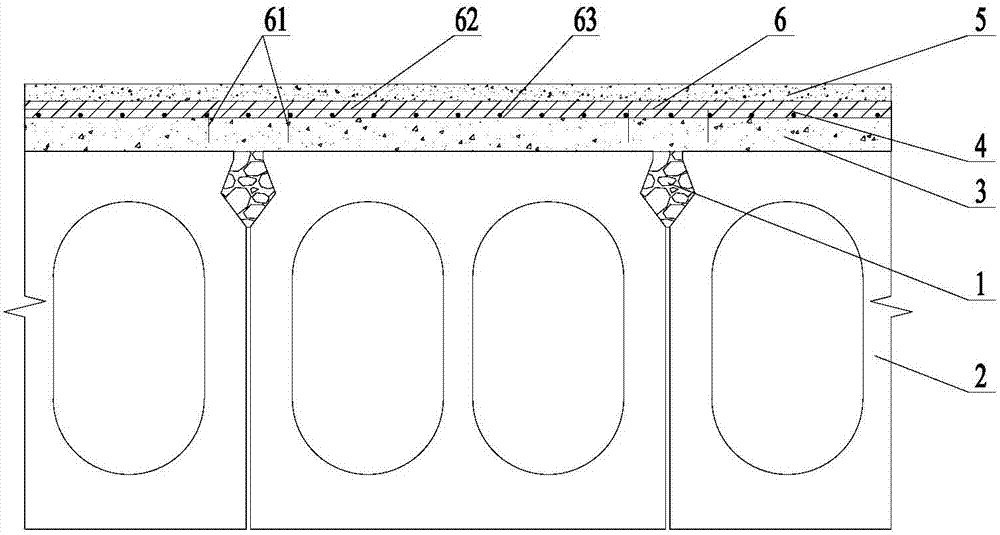

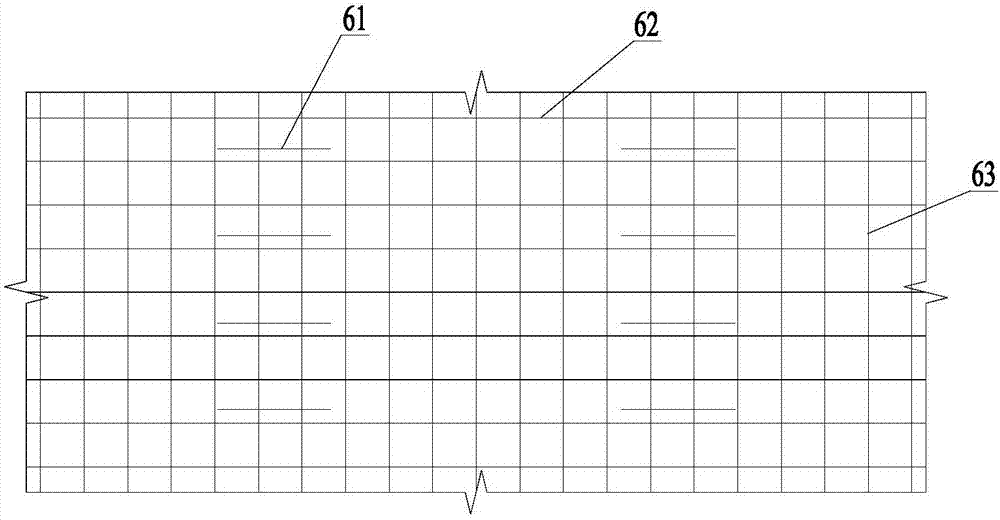

[0044] Such as figure 1 As shown, the ultra-high-performance concrete reinforced hollow slab girder bridge structure of the present invention includes hollow slab girders 2 connected side by side by hinge joints 1 and a bridge deck pavement layer laid on the top of the hollow slab girder 2. The deck pavement layer from bottom to top is an ordinary concrete layer 3, an ultra-high performance concrete reinforcement layer 4 and an asphalt concrete layer 5; wherein, the ultra-high performance concrete reinforcement layer 4 is internally provided with a steel structure 6 connected to the ordinary concrete layer , in order to improve the bearing capacity of the reinforced hollow slab girder bridge.

[0045] In this embodiment, the thickness of the ordinary concrete layer 3 is 8 cm, the thickness of the reinforced ultra-high performance concret...

Embodiment 3

[0051] This embodiment is the reinforcement method of the hollow slab girder bridge structure reinforced by ultra-high performance concrete described in Embodiment 2. Its specific steps are as follows: during construction, the previously laid asphalt concrete layer (about 6 ~ 10mm) to expose the ordinary concrete layer; along both sides of the hinge joint, insert steel bars on the ordinary concrete layer; clean up the ordinary concrete layer (no special treatment such as chiseling) and lay reinforcement mesh, the reinforcement mesh includes a layer Horizontal steel and a layer of longitudinal steel bars; then pour a thin layer of ultra-high performance concrete on the ordinary concrete layer, and bury the implanted steel bars and steel mesh in it to form an ultra-high performance concrete reinforcement layer (about 3-5mm); the pouring is completed Afterwards, the ultra-high-performance concrete reinforcement layer is cured at room temperature for 2 hours, and then the asphalt c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com