Preparation method of N/S doubly doped metallic carbon compound material

A metal-carbon composite and double doping technology, applied in the field of materials science, can solve the problems of poor cycle stability of lithium-ion batteries, achieve high scientific research value, improve cycle stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

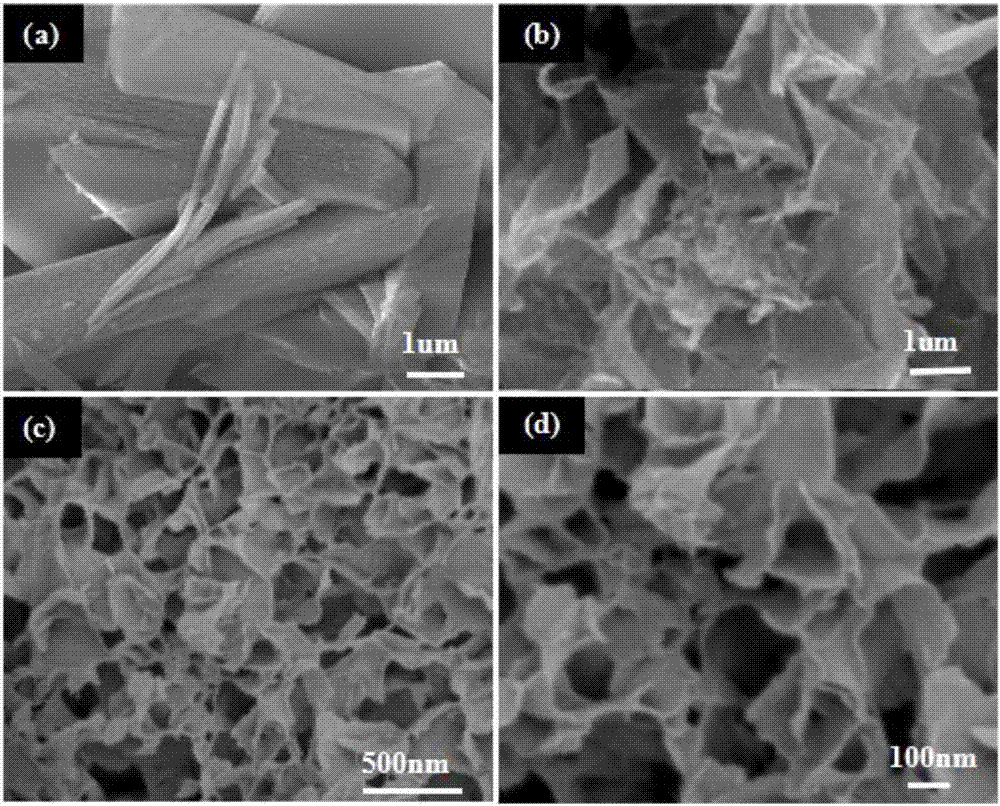

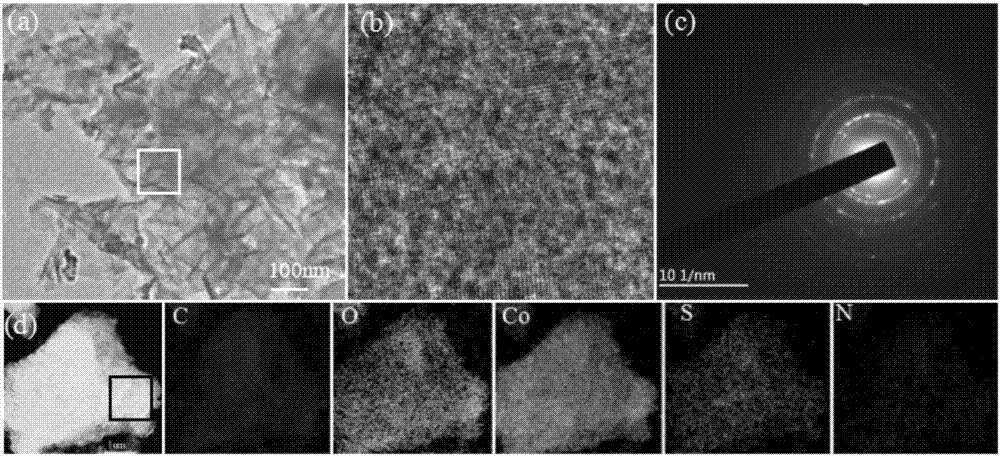

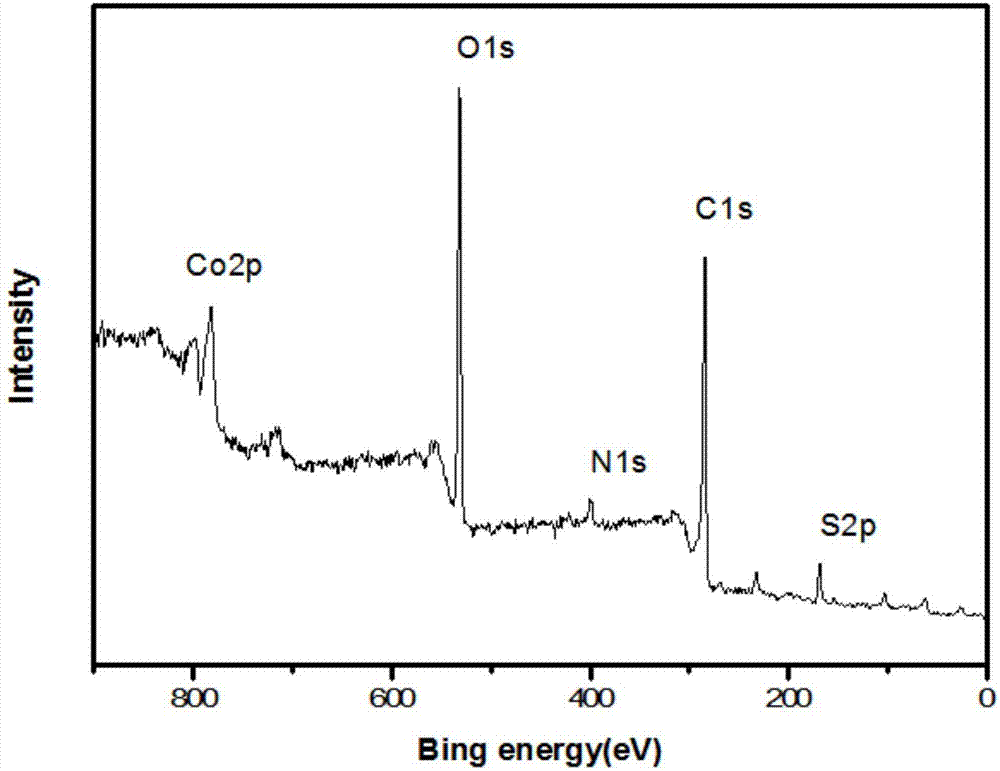

[0018] An N / S double-doped metal-carbon composite material contains Co, C, N, S, and O elements.

[0019] The above-mentioned N / S double-doped metal-carbon composite material preparation method specifically includes the following steps:

[0020] 1) A step for preparing an organic complex material; dissolving dithizone in ethanol, and then adding a metal atom precursor, the molar ratio of the dithizone organic ligand to the metal atom precursor is 2:1, The metal atom is cobalt, and the mixed solution is placed on a stirring table at 45 degrees and stirred for 30 minutes, and then dried in a blast oven at 60 degrees;

[0021] 2) A preparation step for preparing N / S double-doped metal-carbon composite materials. The organic complex obtained after drying is placed in a tube furnace, and kept at 600 degrees for two hours under nitrogen conditions. The heating rate is at 1°C / min, naturally lowered to room temperature, acidified with 1 mol of hydrochloric acid, and finally activated...

Embodiment 2

[0023] Prepare the obtained N / S double-doped metal-carbon composite material into an electrode sheet

[0024] 1) Grind the prepared active material, acetylene black and binder into a slurry at a mass ratio of 8:1:1.

[0025] 2) Pull the slurry on the copper foil and dry it under vacuum at 80 degrees overnight.

Embodiment 3

[0027] The obtained N / S double-doped metal-carbon composites were tested for electrochemical performance

[0028] 1) The dried electrode material is cut into pieces, and a 2032 battery case is selected for assembly in a glove box.

[0029] 2) After the assembled battery was left to dry overnight, the electrochemical performance test was performed with blue dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com