a g-c 3 no 4 Nanosheet and its preparation method and application

A technology of g-c3n4 and nanosheets, which is applied in the field of nanomaterials and photodegradation, can solve the problems of high equipment requirements, low cost, and short cycle, and achieve the effects of efficient use of solar energy, less waste discharge, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

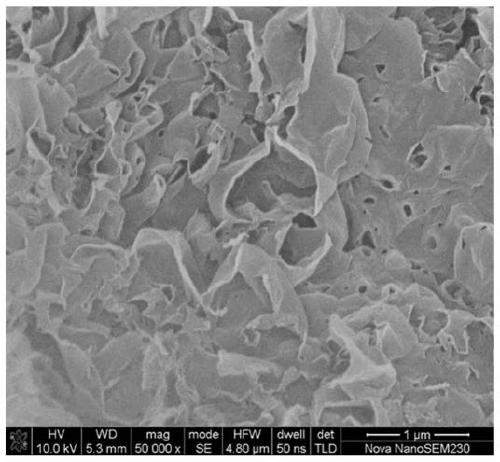

[0034] A g-C of the present invention 3 N 4 Nanosheets, sheet-like structures such as figure 1 As shown, the atomic force microscope (AFM) image is shown in Figure 4 As shown, the nitrogen adsorption curve is shown in Figure 5 shown. Depend on Figure 4 , Figure 5 It can be seen that the g-C prepared in this example 3 N 4 The thickness of the nanosheet is 3.07nm, and the specific surface area is 103.24m 2 / g.

[0035] g-C of this example 3 N 4 The preparation method of nano sheet, comprises the following steps:

[0036] (1) Weigh 2.31g of cyanuric acid and 0.26g of melamine (the molar ratio of cyanuric acid to melamine is 9:1) and mix and grind them in a mortar for 30min to prepare a precursor; (2) transfer the precursor to Put the crucible in a muffle furnace and calcinate at 550°C for 4h in an air atmosphere, and cool down to room temperature naturally to obtain g-C 3 N 4 Nanosheets.

[0037] Weigh 10 mg of the prepared material and disperse it in 100 mL of 1...

Embodiment 2

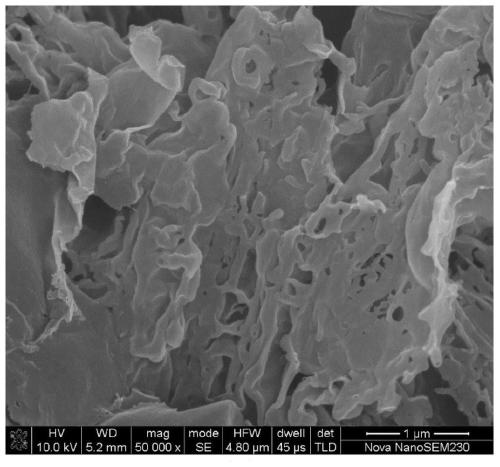

[0039] A g-C of the present invention 3 N 4 Nanosheets, sheet-like structures such as figure 2 As shown, the sheet thickness is 10nm, and the specific surface area is 31.21m 2 / g.

[0040] g-C of this example 3 N 4 The preparation method of nano sheet, comprises the following steps:

[0041] (1) Weigh 2.06g cyanuric acid and 0.52g melamine and mix and grind for 30min in a mortar, (the molar ratio of cyanuric acid and melamine is 4:1) to prepare a precursor; (2) transfer the precursor to Put the crucible in a muffle furnace and calcinate at 550°C for 4h in an air atmosphere, and cool down to room temperature naturally to obtain g-C 3 N 4 Nanosheets.

[0042] Weigh 10 mg of the prepared material and disperse it in 100 mL of 10 mg / L phenol solution. After 30 min of dark treatment, it begins to irradiate with visible light for 210 min. Samples are taken every 30 min for liquid chromatography analysis to obtain the degradation rate of phenol.

Embodiment 3

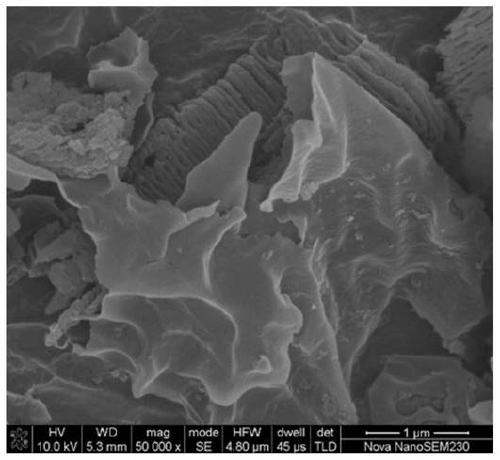

[0044] A g-C of the present invention 3 N 4 Nanosheets, whose sheet-like structure is as image 3 As shown, the sheet thickness is 20nm and the specific surface area is 24.37m 2 / g; combine figure 1 , figure 2 It can be seen that the g-C prepared in this example 3 N 4 Nano sheet is thicker than embodiment 1,2.

[0045] g-C of this example 3 N 4 The preparation method of nano sheet, comprises the following steps:

[0046] (1) Weigh 1.29g cyanuric acid and 1.26g dicyandiamide (the molar ratio of cyanuric acid to dicyandiamide is 2:3) and mix and grind for 30min in a mortar to prepare the precursor; (2) The precursor was transferred to a crucible, and the crucible was placed in a muffle furnace and calcined at 550 °C for 4 h in an air atmosphere, and cooled naturally to room temperature to obtain g-C 3 N 4 Nanosheets.

[0047] Weigh 10 mg of the prepared material and disperse it in 100 mL of 10 mg / L phenol solution. After 30 min of dark treatment, it begins to irradi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com