Preparation method for electrochromism film with molybdenum-doped tungsten oxide nanometer structure for screen printing

A nanostructure and screen printing technology, applied in tungsten oxide/tungsten hydroxide, optics, instruments, etc., can solve the problems of unfavorable lithium ion intercalation and extraction, poor energy utilization rate, long response time, etc., and achieve low cost, The effect of small size and low process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

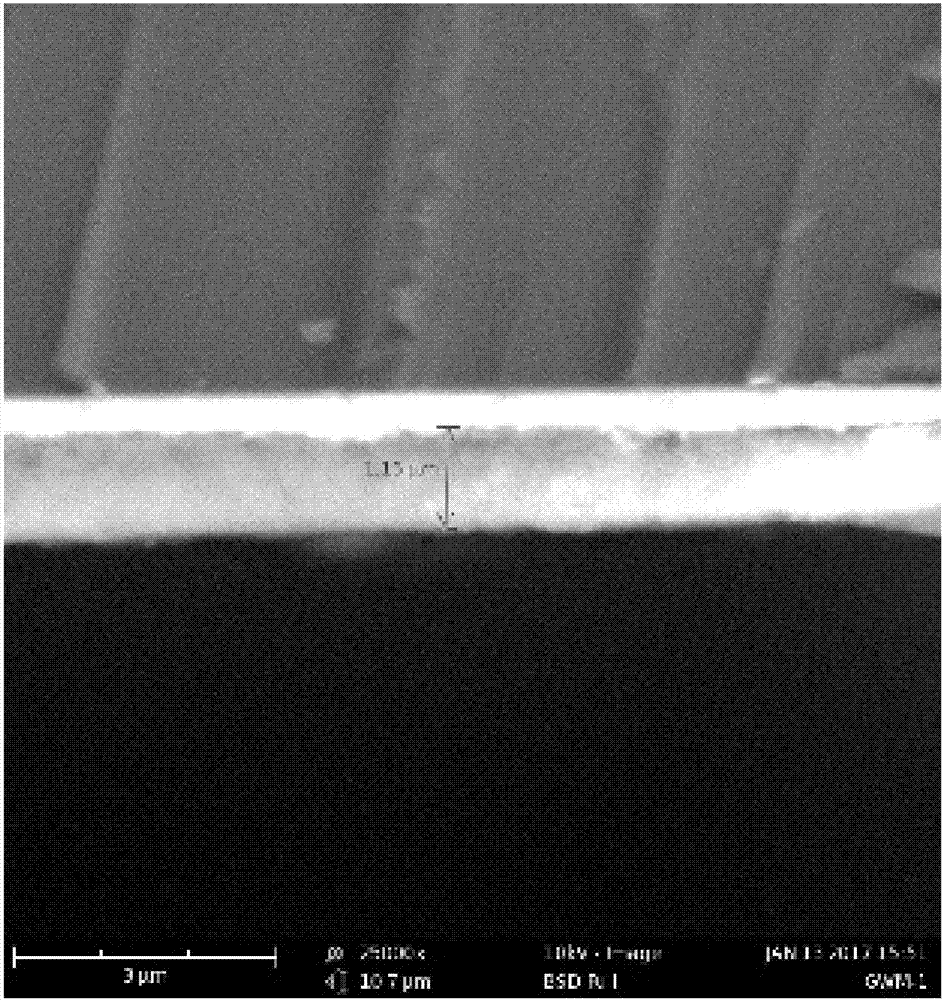

[0028] a. Dissolve 5g of tungstic acid in 60mL of 30% hydrogen peroxide, heat in an oil bath to 95°C, stir until a clear solution is obtained, add 1.44g of molybdenum oxide, 70mL of ethylene glycol and 70mL of deionized water into the resulting clear solution , raise the temperature of the oil bath to 120°C, condense and reflux for 10 hours to obtain the nano-tungsten oxide sol, then rotate it at 10,000 rpm for 20 minutes, pour off the supernatant, and finally wash the precipitate with ionized water and ethanol;

[0029] b. Dissolve ethyl cellulose in ethanol at room temperature, the mass ratio of ethyl cellulose to ethanol is 1:10, stir to obtain a clear and transparent sol, take 15g of the obtained sol and add 12g terpineol and 3g molybdenum doping The tungsten oxide nano-sol was prepared by rotary evaporation of the organic solvent at 90°C to obtain the molybdenum-doped tungsten oxide nano-slurry;

[0030] c. Sonicate the ITO or FTO conductive glass with detergent, deionize...

Embodiment 2

[0035] a. Dissolve 5g of tungstic acid in 60mL of 30% hydrogen peroxide, heat the oil bath to 95°C, and stir until a clear solution is obtained. Add 1.44g of molybdenum oxide, 70mL of ethylene glycol and 70mL of deionized water to the obtained clear solution, raise the temperature of the oil bath to 110°C, and reflux for 12 hours to obtain tungsten oxide nanosol. Then, centrifuge at a speed of 10000rpm / min for 20min, pour off the supernatant; finally use ionized water and ethanol to wash the precipitate respectively;

[0036] b. Dissolve ethyl cellulose in ethanol at room temperature, the mass ratio of ethyl cellulose to ethanol is 1:5, and stir to obtain a clear and transparent sol. Next, 9 g of terpineol and 3 g of molybdenum-doped tungsten oxide nano-sol were added to 18 g of clarified ethylcellulose sol, and the organic solvent was rotary evaporated at 90° C. to prepare molybdenum-doped tungsten oxide nano-slurry;

[0037] c. Sonicate the ITO or FTO conductive glass with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com