A kind of magnesium oxalate cement

An oxalate and cement technology, applied in the field of building materials, can solve the problems of limited large-scale application, high construction difficulty, secondary pollution, etc., and achieve the effects of adjustable reaction speed, prolonged setting time, and reduced construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: The composition of this magnesium oxalate cement is: 100g of acidic component, 100g of magnesium oxide, 12g of setting material; wherein the acidic component is potassium hydrogen oxalate; after sintering at 1500°C, the magnesium oxide is passed through 80 mesh Sieve, the sieve residue is not more than 5%; the setting material is 5g of boric acid, 5g of sodium chloride, 2g of sodium citrate, and 40g of water;

[0022] Mix the above raw materials evenly, quickly pour them into a six-unit mold of 20mm*20mm*20mm, vibrate and form on a vibrating table, scrape the upper part, measure the solidification time for 15 minutes, demould after 5 hours and place in the air After natural maintenance to a certain age, its mechanical properties were tested: 1d, 3d, and 7d compressive strengths were 32.52Mpa, 33.33Mp, and 33.87Mpa, respectively.

Embodiment 2

[0023] Example 2: The magnesium oxalate cement composition is: 100g of acidic component, 100g of magnesium oxide, and 12g of setting material; wherein the acidic component is potassium hydrogen oxalate; after sintering at 900°C, the magnesium oxide is passed through 80 mesh Sieve, the sieve residue is not more than 5%; the setting material is 5g of boric acid, 5g of sodium chloride, 2g of sodium citrate, and 40g of water;

[0024] Mix the above raw materials evenly, quickly pour them into a six-unit mold of 20mm*20mm*20mm, vibrate and form on a vibrating table, scrape the upper part, and measure the solidification time to be 13 minutes, demould after 5 hours and place in the air Naturally preserved to a certain age, its mechanical properties were tested: 1d, 3d, and 7d compressive strengths were 32.15Mpa, 32.96Mp, and 33.02Mpa, respectively.

Embodiment 3

[0025] Embodiment 3: The composition of this magnesium oxalate cement is: 100g of acidic component, 130g of magnesium oxide, 13g of setting-adjusting material; wherein the acidic component is oxalic acid dihydrate; the setting-adjusting material is 10g of borax, 3g of sodium chloride , using 55g of water;

[0026] Mix the above raw materials evenly, quickly pour them into a six-unit mold of 20mm*20mm*20mm, vibrate and form on a vibrating table, scrape the upper part flat, measure the solidification time for 6 minutes, demould after 5 hours and place in the air After natural curing to a certain age, its mechanical properties were tested: 1d, 3d, and 7d compressive strengths were 31.52Mpa, 32.06Mp, and 32.98Mpa, respectively.

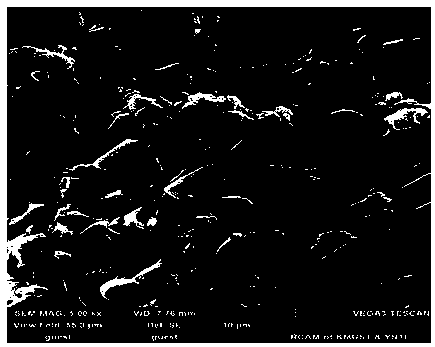

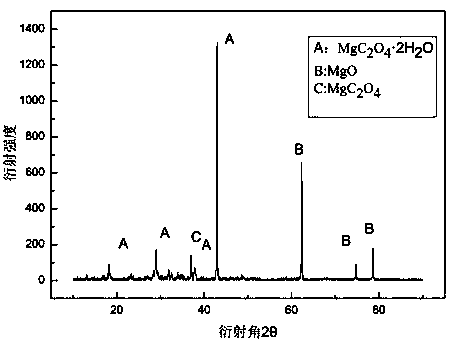

[0027] The material was subjected to SEM morphology analysis, the results are shown in figure 1 , it can be seen from the figure that the cured body is closely combined, and the adjacent particles are connected to each other to form a gel material with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com