Preparation method of 1-amino indole derivative

An aminoindole derivative and a derivative technology are applied in the field of preparation of 1-aminoindole derivatives, which can solve the problems of unfriendly environment, early preparation of substrates, harsh reaction conditions and the like, and achieve strong reaction specificity, Post-processing green, easy post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

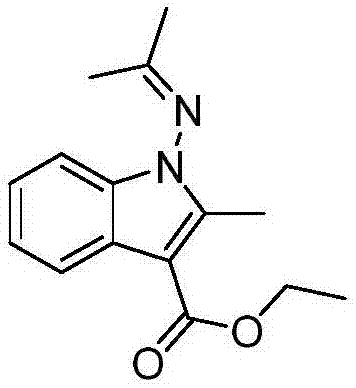

[0020] Preparation of 1-(prop-2-imino)-2-methylindole-3-carboxylic acid ethyl ester,

[0021]

[0022] 0.2 mmol of phenylhydrazine hydrochloride, 0.3 mmol of ethyl 2-diazo-3-oxobutyrate, 0.005 mmol of dichloro(pentamethylcyclopentadienyl) rhodium (III) dimer, 0.2 mmol of sodium acetate Add to the reaction tube, add 0.4 mmol acetone and 2 ml methanol in nitrogen atmosphere, place in an oil bath at 80 °C, react for 12 h in a nitrogen protected atmosphere, remove the heat source from the reaction, and cool to room temperature. The reaction solution was concentrated and purified by column chromatography to obtain 45 mg of the target product with a yield of 87%. The NMR characterization of this compound is as follows: 1 H NMR (400MHz, CDCl 3 ) 8.15 (d, J=7.6Hz, 1H), 7.24-7.14 (m, 2H), 6.96 (d, J=7.9Hz, 1H), 4.40 (q, J=14.2, 7.1Hz, 2H), 2.58(s, 3H), 2.38(s, 3H), 1.76(s, 3H), 1.45(t, J=7.1Hz, 3H). 13 C NMR (100MHz, CDCl 3 )δ181.1, 166.1, 141.3, 131.9, 125.0, 121.9, 121.6, 121...

Embodiment 2

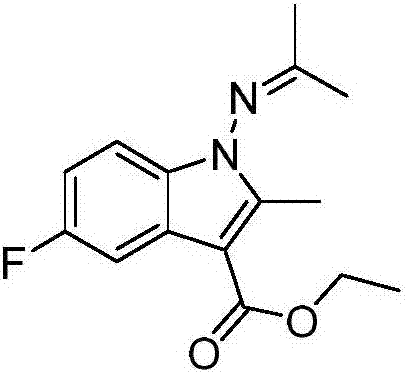

[0024] Preparation of 1-(Propan-2-imino)-2-methyl-5-fluoroindole-3-carboxylic acid ethyl ester

[0025]

[0026] 0.2 mmol of 4-fluorophenylhydrazine hydrochloride, 0.3 mmol of ethyl 2-diazo-3-oxobutyrate, 0.005 mmol of dichloro(pentamethylcyclopentadienyl) rhodium(III) dimer, acetic acid Add 0.2 mmol of sodium to the reaction tube, add 0.4 mmol of acetone and 2 ml of methanol in a nitrogen atmosphere, place in an oil bath at 80 °C, and react for 12 h in a nitrogen-protected atmosphere, remove the heat source from the reaction, and cool to room temperature. The reaction solution was concentrated and purified by column chromatography to obtain 44.1 mg of the target product with a yield of 80%. The NMR characterization of this compound is as follows: 1 H NMR (400MHz, CDCl 3 )δ7.80 (dd, J=9.9, 2.2Hz, 1H), 6.93 (dd, J=8.8, 2.4Hz, 1H), 6.91-6.86 (m, 1H), 4.40 (q, J=7.1Hz, 2H) ), 2.57(s, 3H), 2.40(s, 3H), 1.78(s, 3H), 1.45(t, J=7.1Hz, 3H). 13 C NMR (100MHz, CDCl 3 )δ181.5, 16...

Embodiment 3

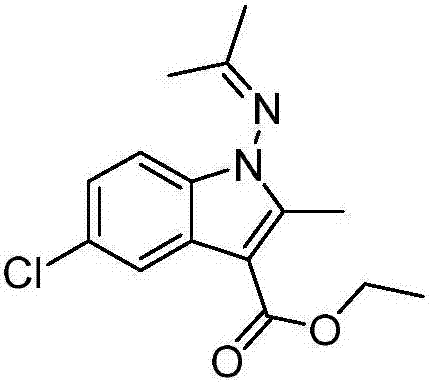

[0028] Preparation of 1-(Propan-2-imino)-2-methyl-5-chloroindole-3-carboxylic acid ethyl ester

[0029]

[0030] 0.2 mmol of 4-chlorophenylhydrazine hydrochloride, 0.3 mmol of ethyl 2-diazo-3-oxobutyrate, 0.005 mmol of dichloro(pentamethylcyclopentadienyl) rhodium(III) dimer, acetic acid Add 0.2 mmol of sodium to the reaction tube, add 0.4 mmol of acetone and 2 ml of methanol in a nitrogen atmosphere, place in an oil bath at 80 °C, and react for 12 h in a nitrogen-protected atmosphere, remove the heat source from the reaction, and cool to room temperature. The reaction solution was concentrated and purified by column chromatography to obtain 45.1 mg of the target product with a yield of 77%. The NMR characterization of this compound is as follows: 1 H NMR (400MHz, CDCl 3 ) 8.12 (d, J=2.0Hz, 1H), 7.13 (dd, J=8.6, 2.0Hz, 1H), 6.88 (d, J=8.6Hz, 1H), 4.41 (q, J=7.1Hz, 2H), 2.57(s, 3H), 2.40(s, 3H), 1.77(s, 3H), 1.46(t, J=7.1Hz, 3H). 13 C NMR (100MHz, CDCl 3 )δ181.6, 165.6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com