A kind of au-tio 2-x Catalysts and their applications

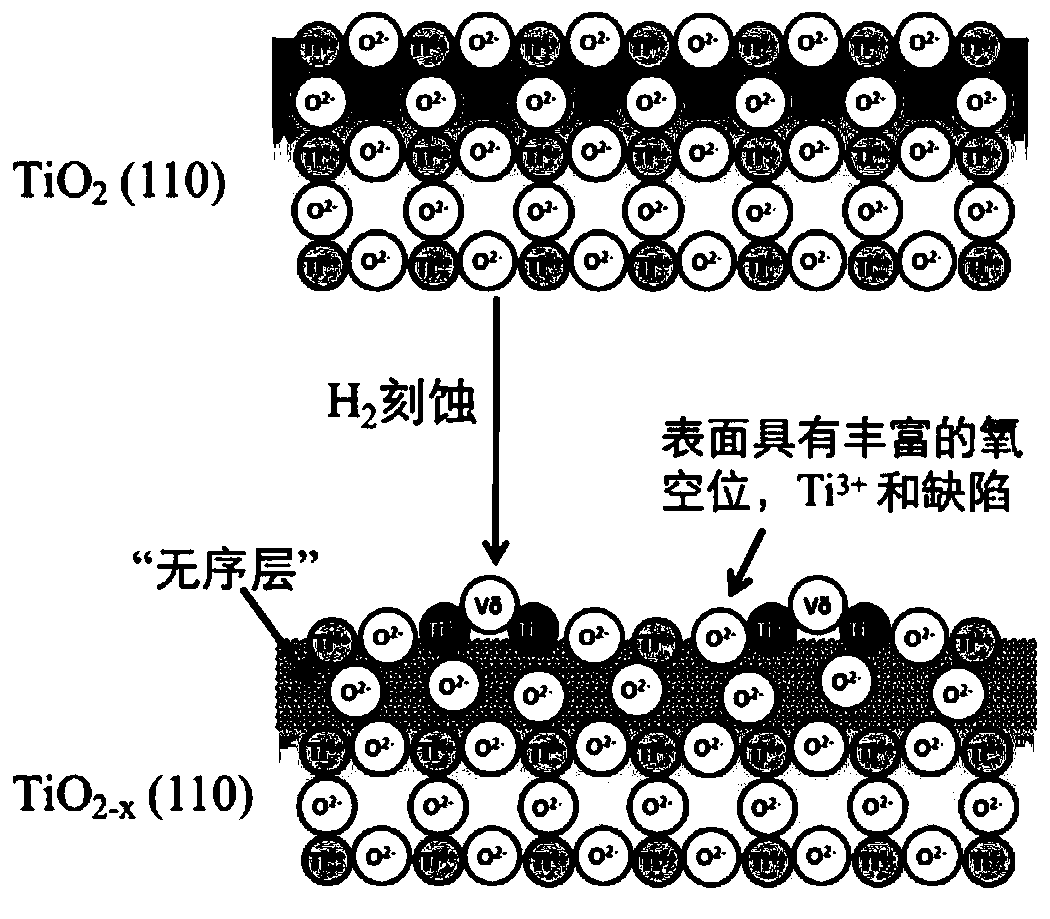

An au-tio2-x, catalyst technology, applied in physical/chemical process catalysts, catalyst carriers, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor TiO2 carrier effect and low WGS activity of catalysts , weak interaction of active metals, etc., to achieve the effect of improving the thermal current transmission efficiency, reducing the ohmic energy barrier, and promoting the reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

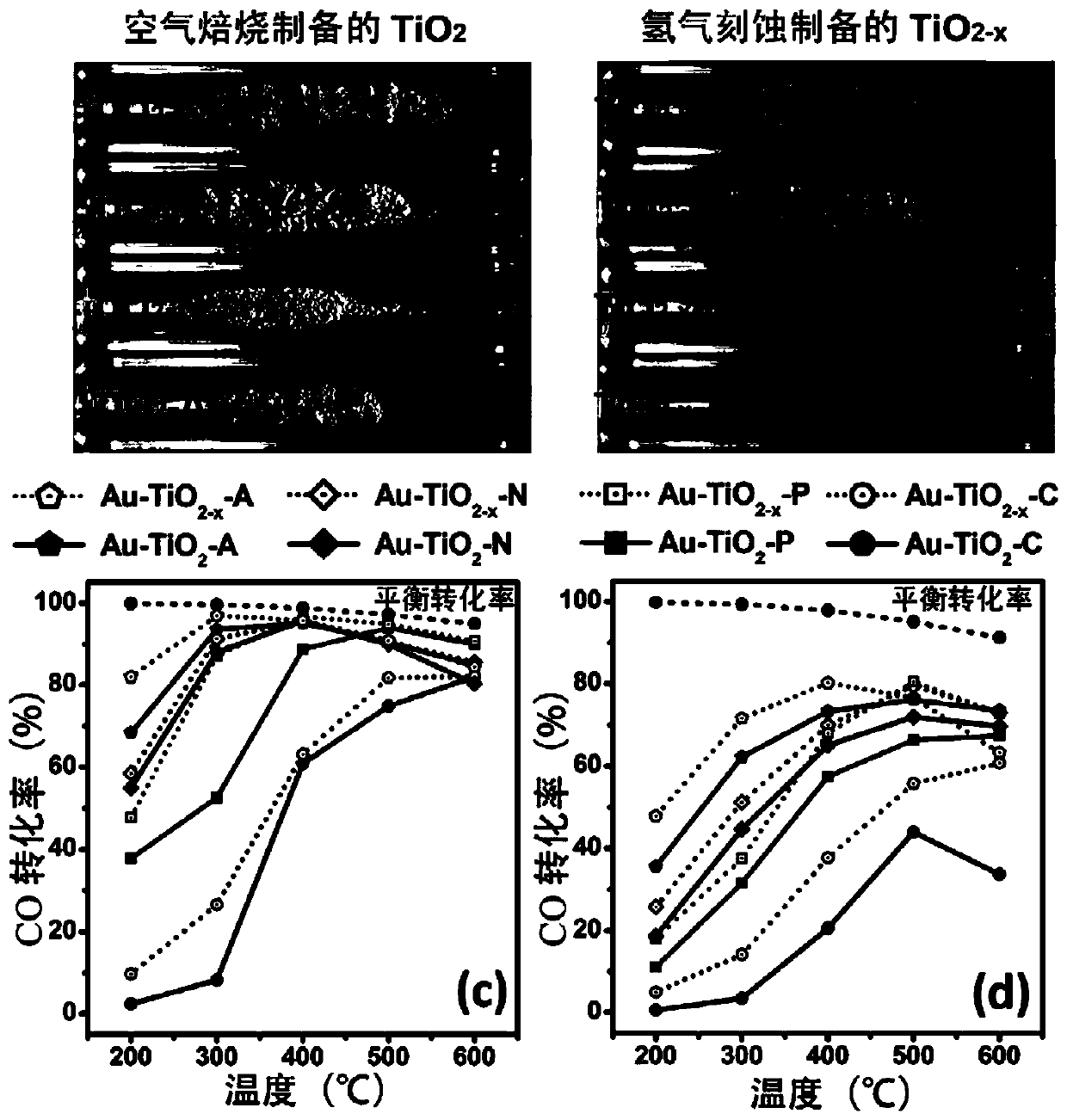

[0064] Example 1 Au-TiO 2 -A and Au-TiO 2-x -Preparation of catalyst

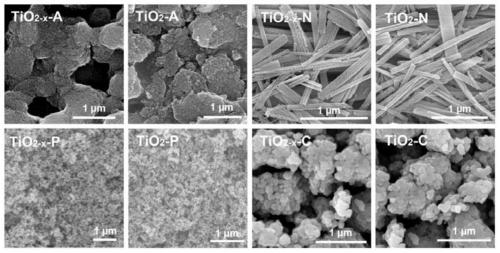

[0065] 1. TiO 2 -A and TiO 2-x - Preparation of A carrier

[0066] (1) Add 4.65g of glacial acetic acid and 120mL of distilled water into a 500mL round bottom flask, then slowly add 20mL of tetra-n-butyl titanate, and stir vigorously at 80°C for 8 hours;

[0067] (2) Transfer the mixture in the round bottom flask to a 120mL polytetrafluoroethylene-lined autoclave, and keep it in an electric oven at 180°C for 24 hours to obtain a precipitate;

[0068] (3) The precipitate was washed with deionized water until the pH of the supernatant was neutral, and dried at 100 °C for 12 hours to obtain solid TiO 2 ;

[0069] (4) the solid TiO 2 Calcined at 550 °C for 4 hours in air atmosphere to obtain white anatase TiO 2 (TiO 2 -A); or solid TiO 2 in H 2 Calcined at 550°C for 4 hours in the atmosphere to obtain black anatase TiO 2 (TiO 2-x -A).

[0070] 2. Au-TiO 2 -A and Au-TiO 2-x -Preparation of cataly...

Embodiment 2

[0073] Example 2 Au-TiO 2 -N and Au-TiO 2-x Preparation of -N catalyst

[0074] 1. TiO 2 -N and TiO 2-x Preparation of -N carrier

[0075] (1) Add 6g of tetra-n-butyl titanate into 18mL of distilled water, and continue to stir for 30min after ultrasonication for 30min; add another 17g of NaOH into 21mL of distilled water, and stir evenly;

[0076] (2) After mixing the two, ultrasonicate for 15 minutes, and continue to stir until milky, then add it to a 50mL polytetrafluoroethylene-lined autoclave, and place it in an electric oven at 200°C for 48 hours to obtain sodium titanate (Na 2 Ti 3 o 7 ) nanoribbons;

[0077] (3) After the reaction, wash the sodium titanate (Na titanate) with distilled water 2 Ti 3 o 7 ) nanoribbons, at 0.1M HNO 3 acidified overnight in medium and dried at room temperature to give the acidified titanate (H 2 Ti 3 o 7 );

[0078] (4) the acidified titanate (H 2 Ti 3 o 7 ) was calcined at 550°C for 4 hours in an air atmosphere to obtain ...

Embodiment 3

[0082] Example 3 Au-TiO 2 -C and Au-TiO 2-x Preparation of -C catalyst

[0083] Commercial TiO 2 (Shanghai Chemical Reagent Co., Ltd.) calcined in air at 550°C for 4 hours to obtain white TiO 2 -C; alternatively, the commercial TiO 2 (Shanghai Chemical Reagent Co., Ltd.) at 550°C in H 2 Calcined in the atmosphere for 4 hours to obtain gray TiO 2-x -C.

[0084] Au-TiO 2-x The preparation method of the -C catalyst is the same as that of the catalyst in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com