High-performance luminescent polyimide, and preparation method and application thereof

A polyimide, high-performance technology, applied in the field of material science, can solve the problem that the photoluminescence efficiency of polyimide is not greatly improved, and achieve a simple and diverse preparation process, excellent mechanical properties, and obvious aggregation-induced luminescence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

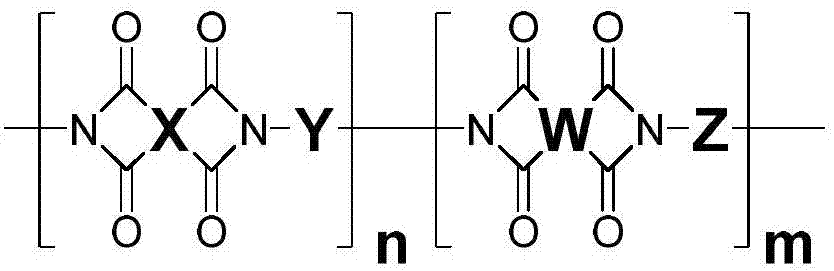

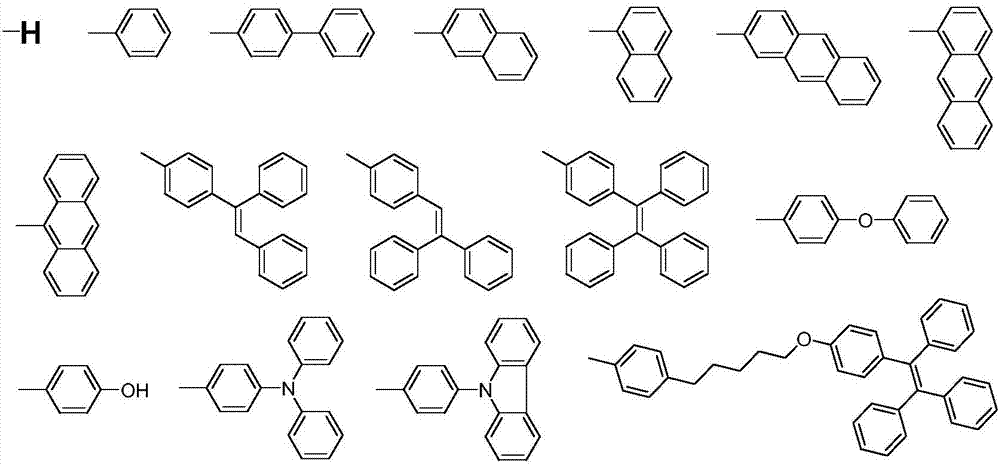

Method used

Image

Examples

Embodiment 1

[0041]At room temperature, 5.1467g (0.01mol)

[0042] Add 5'-(1,2,2-triphenylvinyl)-[1,1':3',1”-terphenyl]-4,4”-diamine and 37 ml of N,N-dimethylformamide to 100ml In the three-necked flask, argon was introduced. After stirring and dissolving completely, 2.2417 g (0.01 mol) of hydrogenated pyromellitic dianhydride was added, and the stirring reaction was continued at room temperature for 36 hours to obtain a homogeneous, transparent and viscous polyamic acid solution. Scrape-coat the obtained polyamic acid solution on a clean glass plate, then place the glass plate in a vacuum oven, and raise the temperature according to the temperature rise program under vacuum: the room temperature is raised to 100°C and then the temperature is kept constant. The whole process takes 60 minutes; and then After the temperature is raised to 200°C, the temperature is kept constant, and the whole process takes 60 minutes; after the temperature is finally raised to 300°C, the temperature is kept ...

Embodiment 2

[0046] At room temperature, 5.1467g (0.01mol)

[0047] Add 5'-(1,2,2-triphenylvinyl)-[1,1':3',1”-terphenyl]-4,4”-diamine and 55ml of N,N-dimethylformamide to 100ml The flask was filled with argon. After stirring and dissolving completely, add 3.1022g (0.01mol) of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, and continue to stir and react at room temperature for 12 hours to obtain a homogeneous, transparent, viscous polyamide acid solution. Add a mixed solution containing 5ml of acetic anhydride and 2.5ml of pyridine to the obtained polyamic acid solution, and after stirring at room temperature for 24 hours, slowly pour the polyimide solution into 1L of methanol to obtain a fibrous or spherical precipitate, which is filtered out After precipitation, dry in an oven. The obtained solid was then dissolved in N,N-dimethylformamide, scraped onto a clean glass plate, placed in a vacuum oven, heated to 100°C for 2 hours, and then heated to 200°C for 2 hours. After cooling...

Embodiment 3

[0051] At room temperature, 5.1467g (0.01mol)

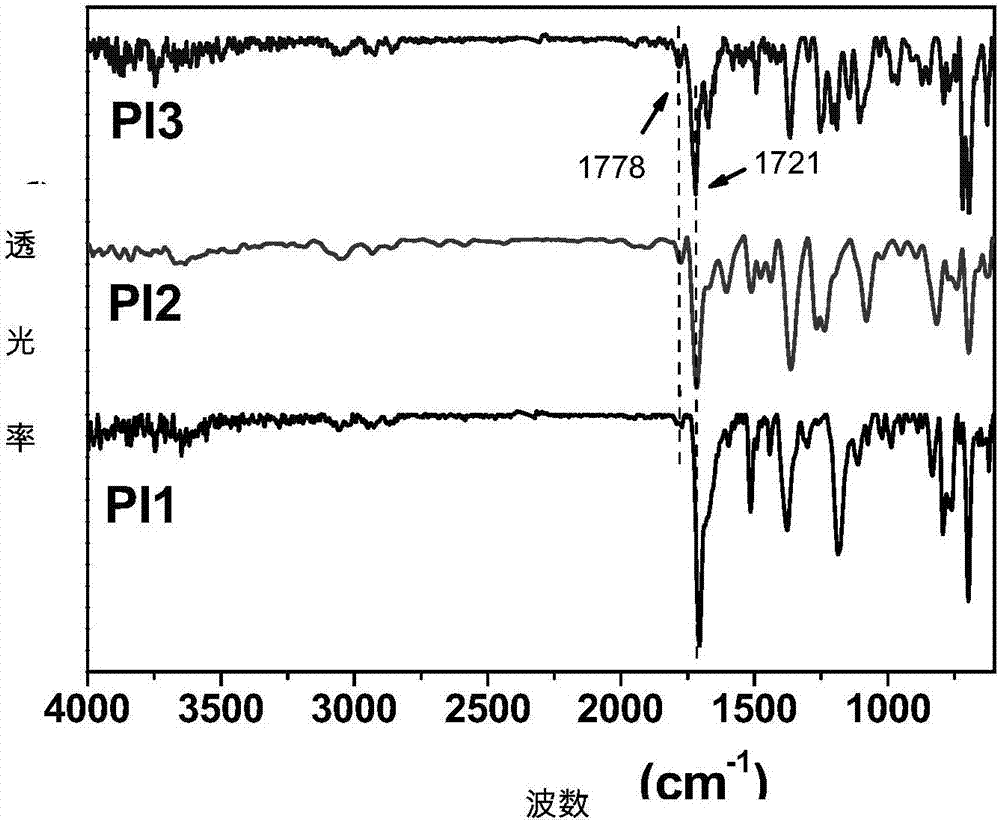

[0052] Add 5'-(1,2,2-triphenylvinyl)-[1,1':3',1”-terphenyl]-3,3”-diamine and 64ml of N,N-dimethylformamide to 100ml The flask was filled with argon. After stirring and dissolving completely, add 4.4424g (0.01mol) 4,4'-hexafluoroisopropylphthalic anhydride, and continue to stir and react at room temperature for 8 hours to obtain a homogeneous, transparent and viscous polyamic acid solution . The polyamic acid was chemically imidized according to the method in Example 2 to obtain a polyimide film PI3. The polyimide film has aggregation-induced luminescent properties, the wavelength corresponding to the strongest fluorescent peak is 533nm, the 5% thermal weight loss temperature is 569°C, and the glass transition temperature is 286°C. The infrared spectrum of the polyimide film is shown in figure 1 The PI3 is shown.

[0053] The molecular structural formula of the high-performance light-emitting polyimide in the present embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com