Preparation method for hydrophobic montmorillonite clay/isolated soy protein composite film

A technology of soybean protein isolate and Imon clay, which is applied in the field of composite material film, can solve the problems of poor practicability, unstable dispersion of soybean protein isolate, and inconspicuous synergistic effect of clay and soybean protein isolate components, etc. Compatibility and dispersibility, effect of improving surface hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Raw materials are prepared according to the following ratio: the parts mentioned below refer to parts by weight.

[0052]

[0053] (2) Dissolve the hydrophobic Imond clay in the distilled water and disperse it with 1200w ultrasonic wave for 20min;

[0054] (3) dissolving the soybean protein isolate in the dispersion solution obtained in step (2) and mechanically stirring for 10 min at a speed of 500 r / min;

[0055] (4) Add the glycerol into the mixed solution obtained in step (3) and carry out mechanical stirring for 10 min at a speed of 500 r / min;

[0056] (5) Adjust the pH value of the mixed solution obtained in step (4) to 9.2 with 10% sodium hydroxide solution, and perform mechanical stirring for 10 minutes at a speed of 500 r / min;

[0057] (6) Mechanically stirring the mixed solution obtained in step (5) in a water bath at 85° C. for 30 minutes at a speed of 500 r / min;

[0058] (7) After cooling the mixed solution obtained in step (6), pour it into a mold ...

Embodiment 2

[0061] (1) Prepare raw materials according to the following ratio:

[0062]

[0063] (2) Dissolving the hydrophobic Imond clay in the distilled water for 500w ultrasonic dispersion for 20min;

[0064] (3) dissolving the soybean protein isolate in the dispersion solution obtained in step (2) and mechanically stirring for 10 min at a speed of 400 r / min;

[0065] (4) Add the sorbitol into the mixed solution obtained in step (3) and carry out mechanical stirring for 10min at a speed of 400r / min;

[0066] (5) Adjust the pH value of the mixed solution obtained in step (4) to 9.4 with 10% aqueous sodium hydroxide solution, and perform mechanical stirring for 10 minutes at a speed of 400 r / min;

[0067] (6) The mixed solution obtained in step (5) was mechanically stirred and heated in a water bath at 80° C. for 30 minutes at a speed of 400 r / min;

[0068] (7) After cooling the mixed solution obtained in step (6), pour it into a mold and place it in a constant temperature and humi...

Embodiment 3

[0071] (1) Prepare raw materials according to the following ratio:

[0072]

[0073] (2) Dissolve the hydrophobic Imond clay in the distilled water and carry out 800w ultrasonic dispersion for 20min;

[0074] (3) dissolving the soybean protein isolate in the dispersion solution obtained in step (2) and mechanically stirring for 20 min at a speed of 300 r / min;

[0075] (4) Add the glycerol into the mixed solution obtained in step (3) and carry out mechanical stirring for 20min at a speed of 300r / min;

[0076] (5) Adjust the pH value of the mixed solution obtained in step (4) to 9.4 with 10% aqueous sodium hydroxide solution, and perform mechanical stirring for 20 minutes at a speed of 300 r / min;

[0077] (6) Heat the mixed solution obtained in step (5) in a water bath at 82° C. for 30 minutes at a speed of 300 r / min;

[0078] (7) After cooling the mixed solution obtained in step (6), pour it into a mold and place it in a constant temperature and humidity box to dry and for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

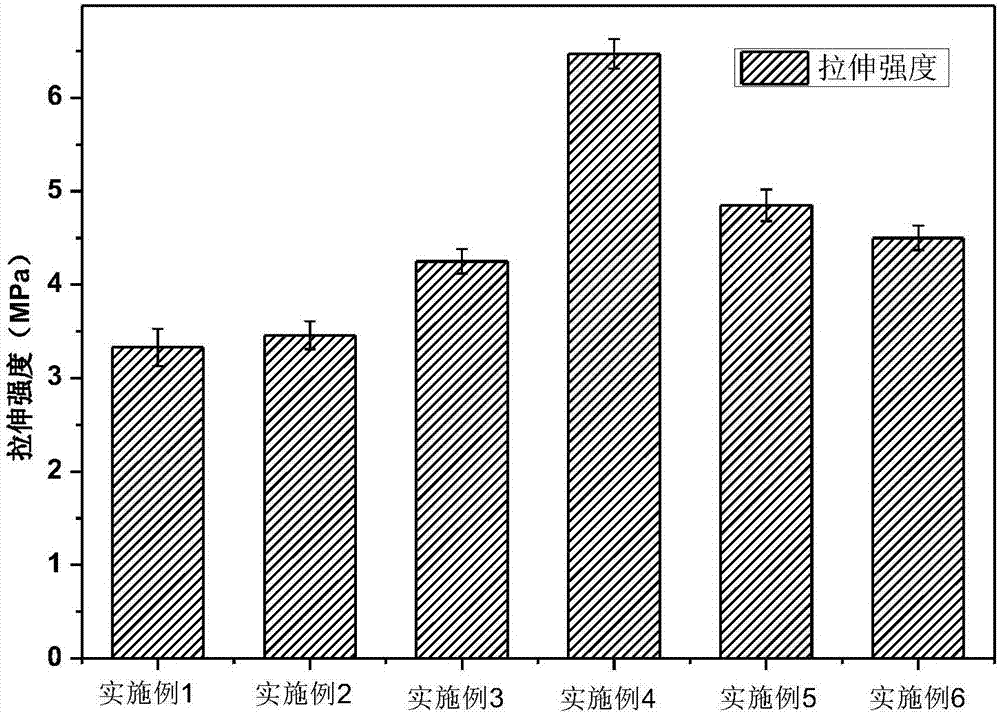

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com