Steel wire rod for hardware tool and production method thereof

A technology for hardware tools and production methods, applied in the direction of improving process efficiency, can solve the problems of short service life, wear, and difficulty in bearing high loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

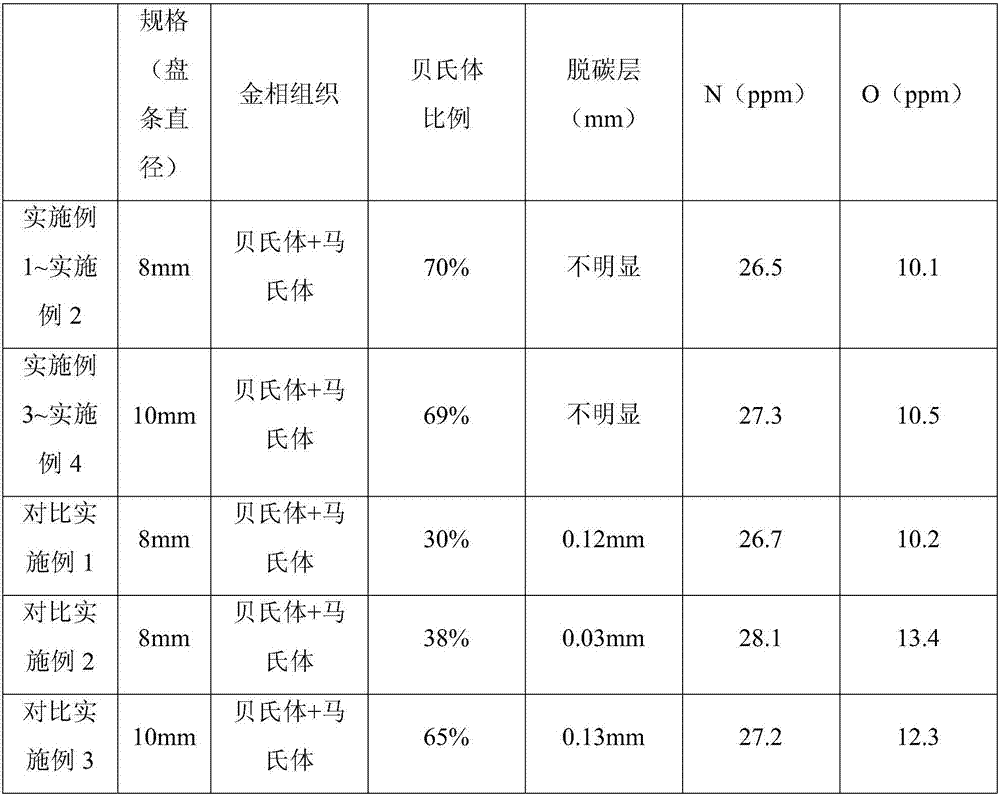

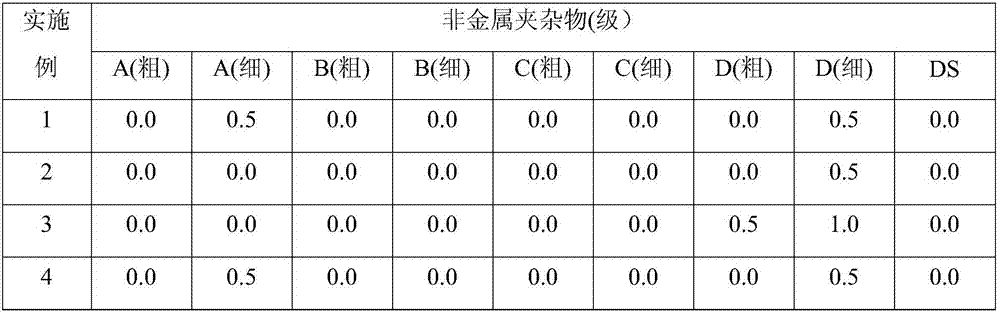

Examples

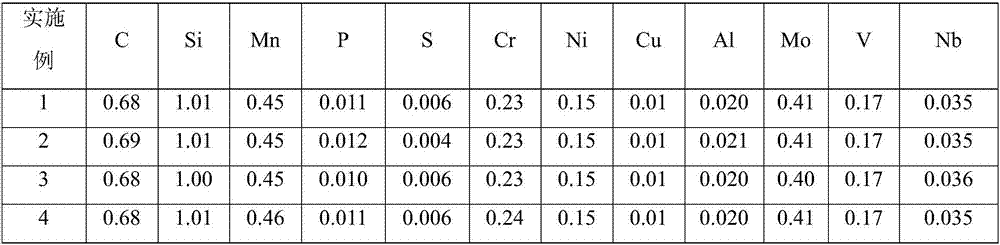

Embodiment 1

[0058] (1) Converter smelting

[0059] Converter is used for high lance smelting, low-phosphorus tapping technology, bottom-blown argon stirring throughout the process, and the steelmaking raw materials used are scrap steel, pig iron and molten iron. Among them, the phosphorus content of molten iron is less than 0.09%, and scrap steel accounts for 9% of the total weight of steelmaking raw materials , pig iron accounts for 4% of the total weight of steelmaking raw materials, the total charge is 138t / furnace, converter smelting takes 14min, tapping [C]0.25%, tapping [P]0.008%, tapping temperature 1653°C, tapping 1 / At 4 o'clock, add aluminum cake 0.60kg / t (relative to the amount of steelmaking raw materials, the same below), silicon manganese 7.2kg / t, ferrosilicon 14.7kg / t, high carbon ferrochromium 3.6kg / t, Nickel plate 1.52kg / t, ferro-vanadium 4.2kg / t, ferro-molybdenum 6.5kg / t, lime 600kg / furnace, synthetic slag 400kg / furnace, the tapping process adopts double slag blocking op...

Embodiment 2

[0076] In step (1), steel scrap accounts for 8.5% of the total weight of steelmaking raw materials, pig iron accounts for 4.5% of the total weight of steelmaking raw materials, and the total charge is 139t / furnace;

[0077] In step (2), it is changed to a continuous pouring furnace, and the temperature of the LF hanging bag is 1575°C;

[0078] In step (3), the temperature of the hanging bag after soft blowing is 1525°C;

[0079] In step (4), the degree of superheat of continuous casting is 23°C, and the casting speed is 0.85m / min;

[0080] All the other operations are the same as in Example 1.

Embodiment 3

[0082] In step (7), the furnace temperature in the second stage of the heating furnace in the wire rod rolling process is 992°C, the furnace temperature in the soaking section is 997°C, the rolling start temperature is 917°C, the finishing rolling temperature is 832°C, and the spinning temperature is 796°C. Example 2 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com