Cloth defect detection method and device based on machine learning

A technology of machine learning and cloth detection, applied in the direction of neural learning methods, instruments, computer components, etc., can solve the problems of high missed detection rate, high false detection rate, and difficulty in meeting industrial needs, so as to achieve a high degree of automation and liberate productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: A method for detecting cloth defects based on machine learning.

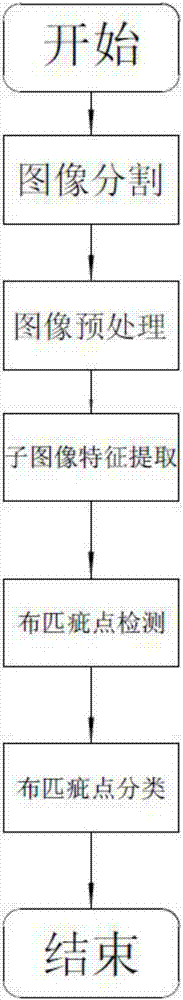

[0045] refer to Figure 1 to Figure 5 As shown in any one, a method for detecting cloth defects based on machine learning specifically includes the following steps:

[0046] Step 1: Image segmentation, in order to facilitate subsequent processing, the collected image is uniformly divided into 256*256 sub-images;

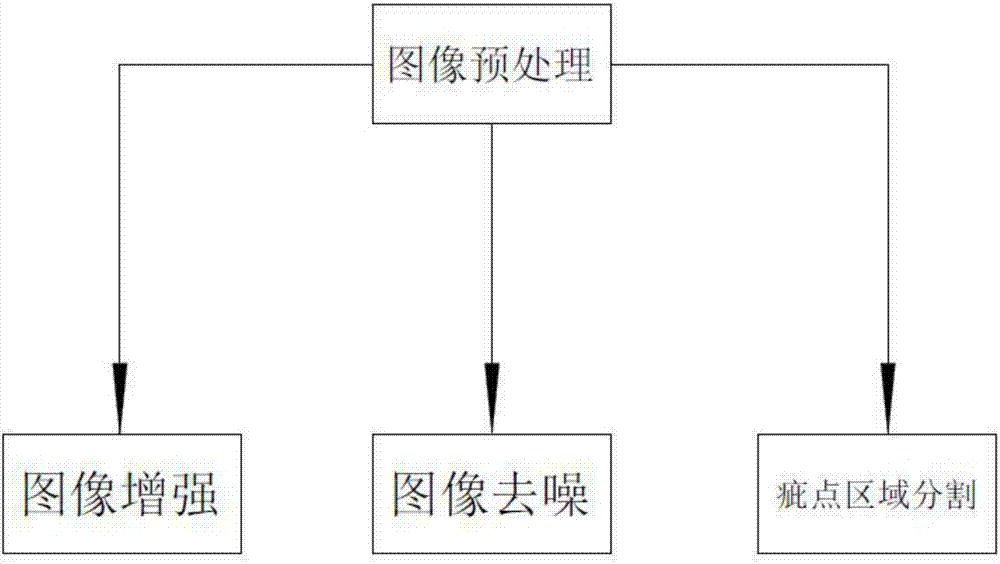

[0047] Step 2: image preprocessing; the step 2 is specifically as follows:

[0048] Step 21: image enhancement, extraction of effective regions;

[0049] Step 22: Image denoising, using a Gaussian filter to remove noise;

[0050] Step 23: Segment the defect area, segment the cloth defect area from the whole image.

[0051] Step 3: sub-image feature extraction, using an image processing method based on Gabor wavelet transform and projection method to extract the feature parameters of the sub-image;

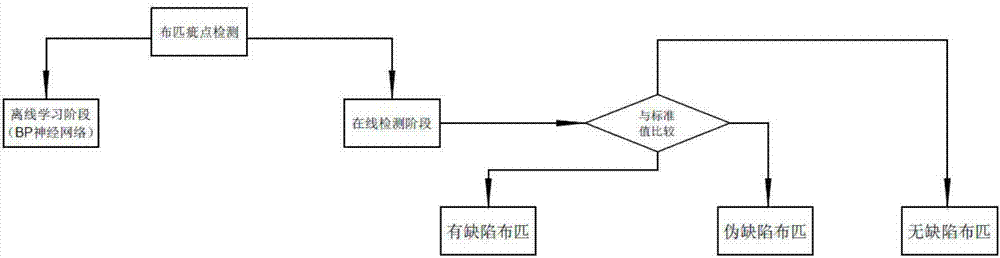

[0052] Step 4: Cloth defect detection; the step 4 is specifically as follows:

...

Embodiment 2

[0064] Embodiment 2: A cloth defect detection device based on machine learning.

[0065] refer to Figure 5 As shown, a detection device based on the machine learning-based cloth defect detection method in Embodiment 1 includes:

[0066] Image acquisition unit 1, described image acquisition unit 1 comprises infrared light source 101 and industrial camera 102, image processing unit 2, described image processing unit 2 comprises industrial computer 201, data communication unit 3, and described data communication unit 3 comprises host computer 301 and the lower computer 302, the action execution unit 4, the action execution unit 4 includes an encoder 401 and a marking machine 402, the encoder 401 detects the speed signal of the moving cloth, and this signal is fed back to the conveyor belt motor, so that the cloth speed and the camera The shooting speed is the same; the upper computer 301 sends the position and type of the detected cloth defect to the lower computer 302, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com