Narrow-neck bottle type porous carbon and redox micromolecule composite supercapacitor energy storage electrode material and preparation method

A technology for supercapacitors and energy storage electrodes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of poor cycle stability and electrochemical capacity decay of composite electrode materials, and achieve the purpose of suppressing loss and excellent performance. Rate characteristics, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]1) Preparation of composite electrode materials

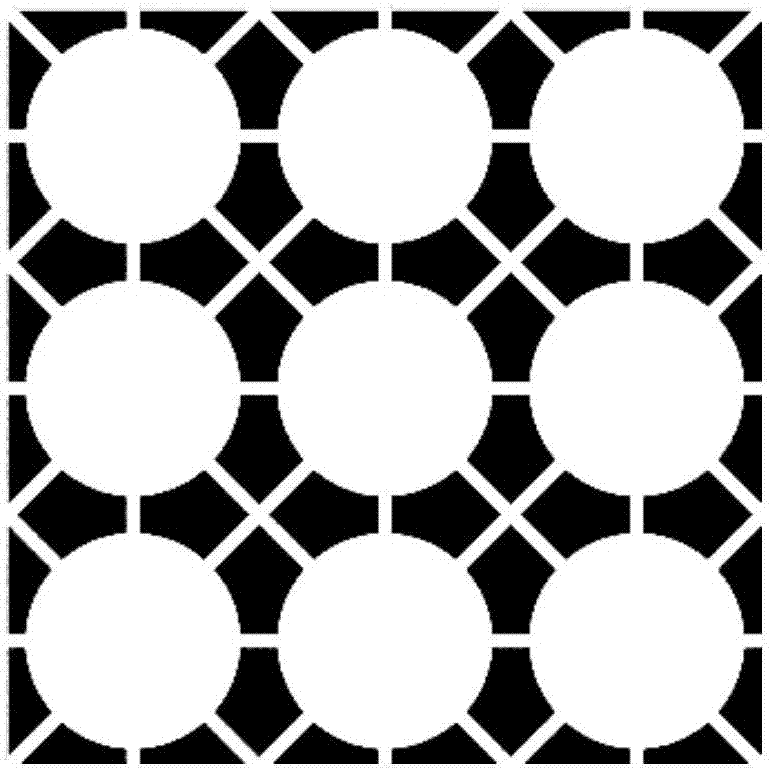

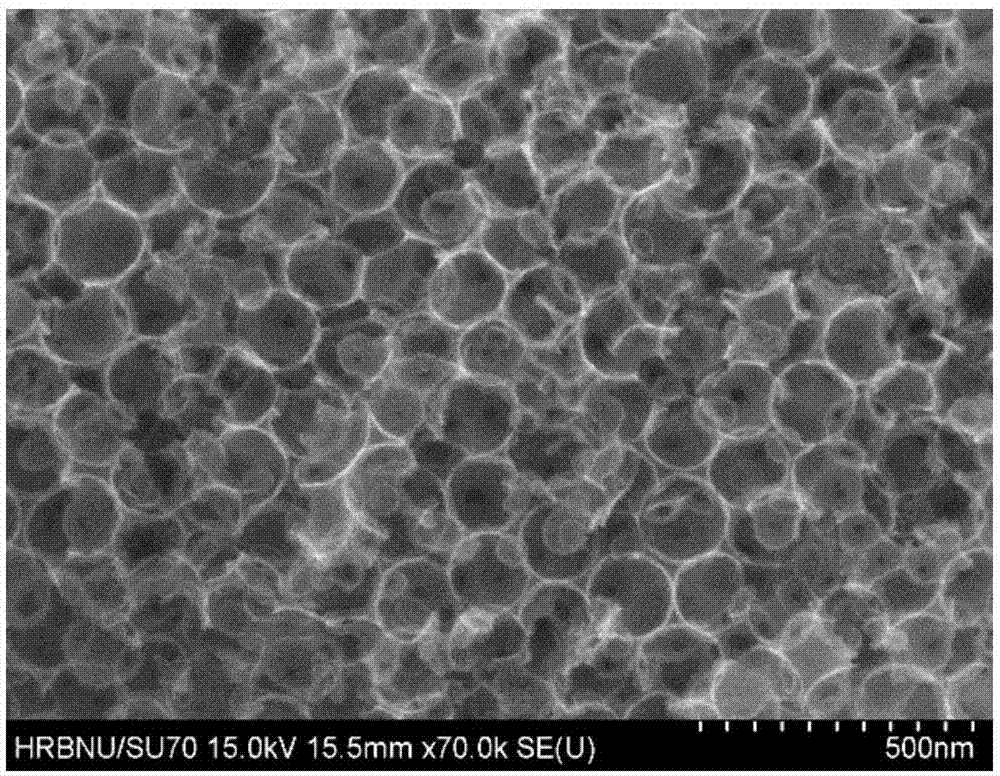

[0038] Take 1g of SiO with an average diameter of 150nm 2 Mix the powder, 0.5g pitch, 0.01g potassium citrate and 50g tetrahydrofuran (THF) evenly, and heat in a water bath at 60°C to evaporate the solvent. Then carbonization was carried out at 850 °C for 2 h in a nitrogen atmosphere in a tube furnace. After natural cooling to room temperature, soak and wash with dilute hydrofluoric acid solution to remove SiO 2 , then washed with distilled water to become neutral, and dried at 100°C for 24 hours to obtain a "flask" type porous carbon (structure as attached figure 1 , 3 shown), the sample is labeled FC.

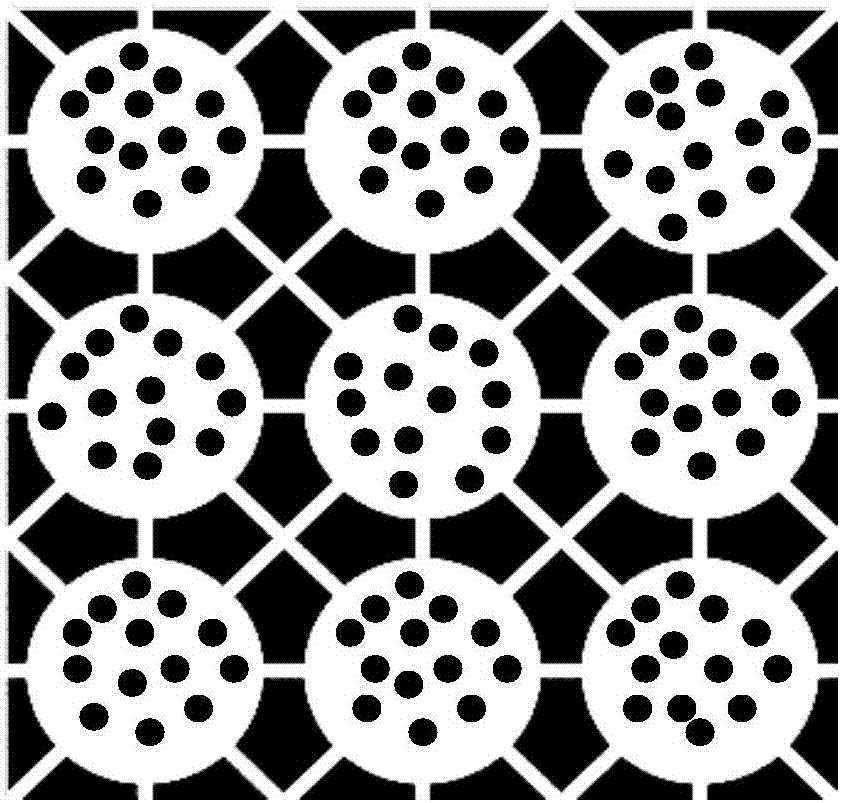

[0039] Immerse equal volumes of FC in 10%wt potassium ferricyanide solution (the weight ratio of potassium ferricyanide to FC is 20:80, soak for 24 hours, vacuum degassing, and dry at 100-150°C to obtain the electrode material FC -K 3 Fe(CN) 6 (if attached figure 2 shown).

[0040] 2) Characterization and descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com