Compound nutrient lick bricks suitable for growth of yaks and production method of compound nutrient lick bricks

A technology of nutrition licking brick and production method, which is applied in the field of low yak breeding, can solve the problems of high salt content, unbalanced nutrition, small use range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A compound nutritional licking brick suitable for the growth of yaks. The compound nutritional licking brick includes bran, rapeseed meal, bentonite, salt, urea, molasses, gypsum and trace mineral elements; to make 1000 kg of licking brick, take 93 kg of bran, Rapeseed meal 155 kg, bentonite 145 kg, salt 205 kg, urea 103 kg, molasses 195 kg, ferrous sulfate 0.35 kg, zinc sulfate 0.3 kg, copper sulfate 0.2 kg, potassium iodide 0.15 kg, cobalt chloride 0.03 kg, magnesium oxide 0.18 kg, copper sulfate 0.1 kg, gypsum 102.7 kg.

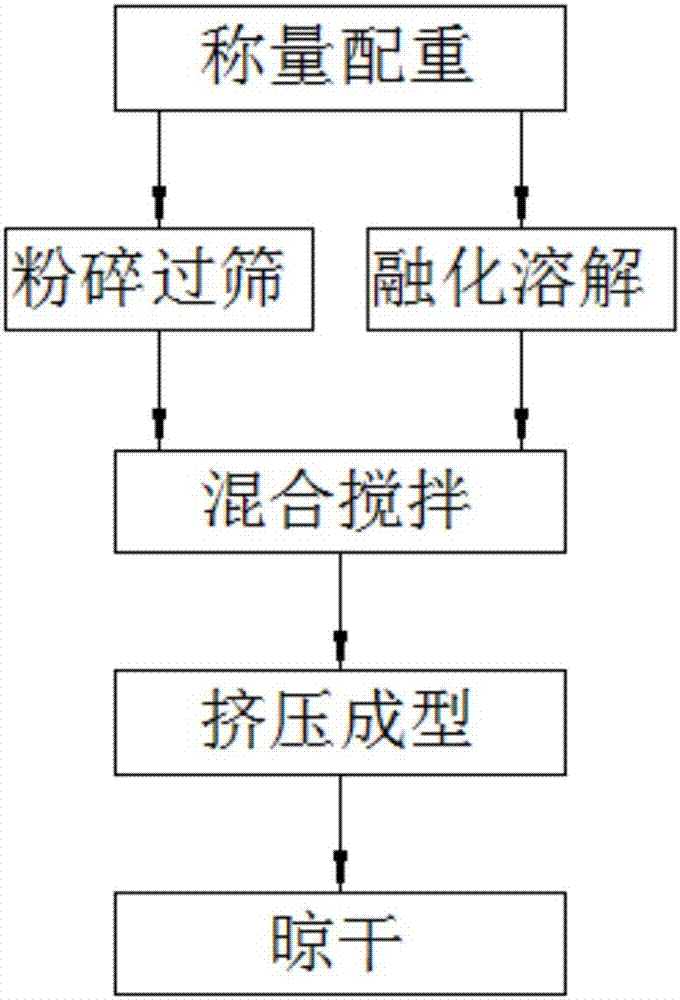

[0024] Concrete production method comprises the following steps:

[0025] as attached figure 1 As shown, first, weigh the counterweight according to the weight ratio;

[0026] Next, pulverize bran, rapeseed meal, bentonite and gypsum respectively, and sieve through a 50-mesh sieve;

[0027] And the trace mineral elements are pulverized and mixed evenly;

[0028] At the same time, the molasses is melted into syrup at 90°C to 95°C.

[0029] Then ...

Embodiment 2

[0032] Take 100 kg of bran, 175 kg of rapeseed meal, 160 kg of bentonite, 210 kg of table salt, 130 kg of urea, 162 kg of molasses, 0.4 kg of ferrous sulfate, 0.3 kg of zinc sulfate, 0.18 kg of copper sulfate, 0.15 kg of potassium iodide, and 0.025 kilogram of cobalt, 0.18 kilogram of magnesia, 0.2 kilogram of copper sulfate, and 57.6 of gypsum; Concrete production method is with embodiment one.

Embodiment 3

[0034] Take 120 kg of bran, 150 kg of rapeseed meal, 145 kg of bentonite, 215 kg of salt, 135 kg of urea, 190 kg of molasses, 0.4 kg of ferrous sulfate, 0.35 kg of zinc sulfate, 0.2 kg of copper sulfate, 0.2 kg of potassium iodide, cobalt chloride 0.025 kilogram, 0.18 kilogram of magnesium oxide, 0.2 kilogram of copper sulfate, 43.4 kilogram of gypsum; Concrete production method is with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com