Solid-phase microextraction coating based on metalloporphyrin microporous polymer, and preparation and application thereof

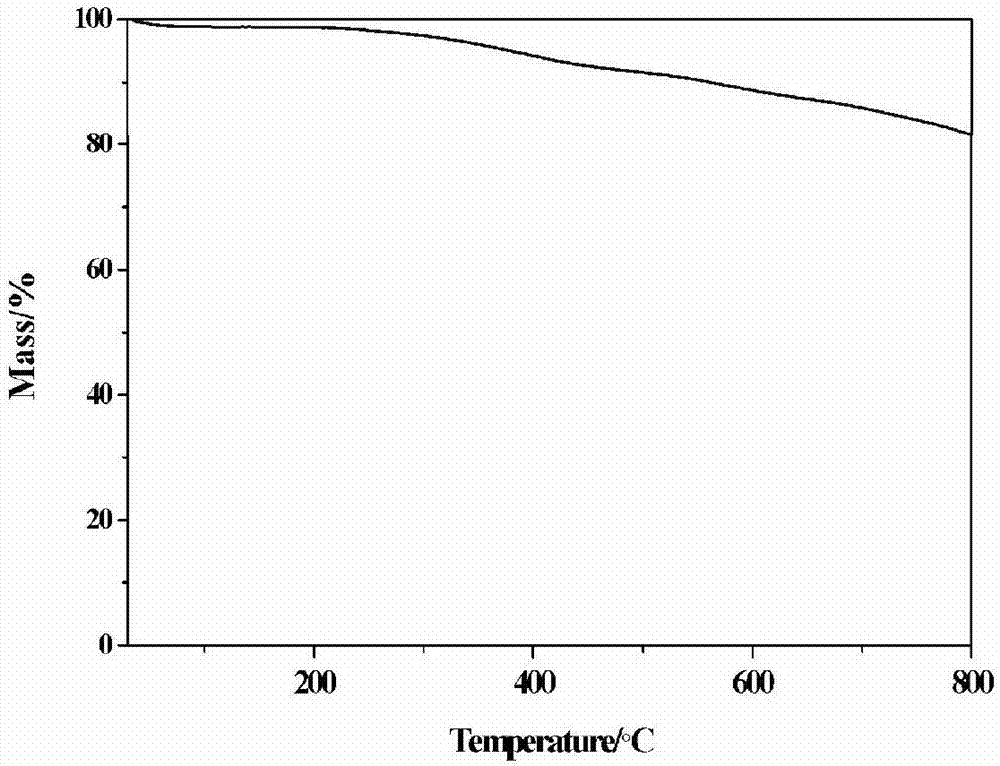

A technology of microporous polymers and metalloporphyrins, which is applied in the fields of analytical chemistry and environmental analysis, can solve the problems of few separation and analysis applications, and achieve the effects of easy operation and mastery, high thermal stability, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

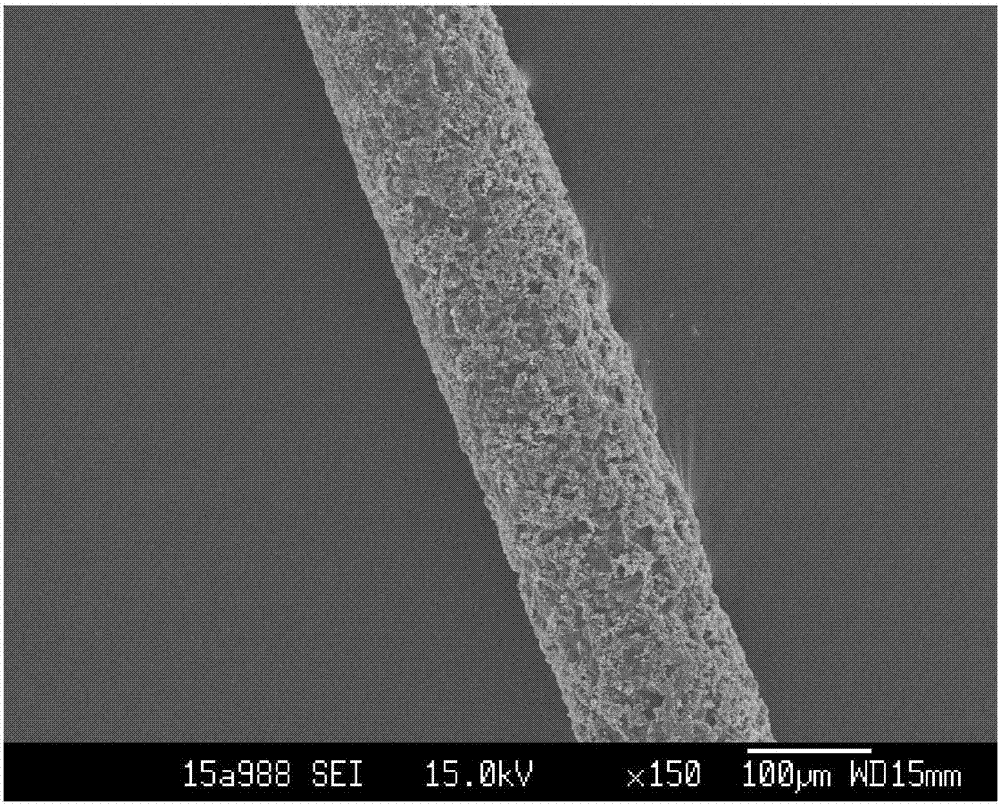

[0045] The preparation of the solid-phase microextraction coating based on the metalloporphyrin microporous organic polymer comprises the following steps:

[0046] (1) Preparation of Metalloporphyrin Suspension

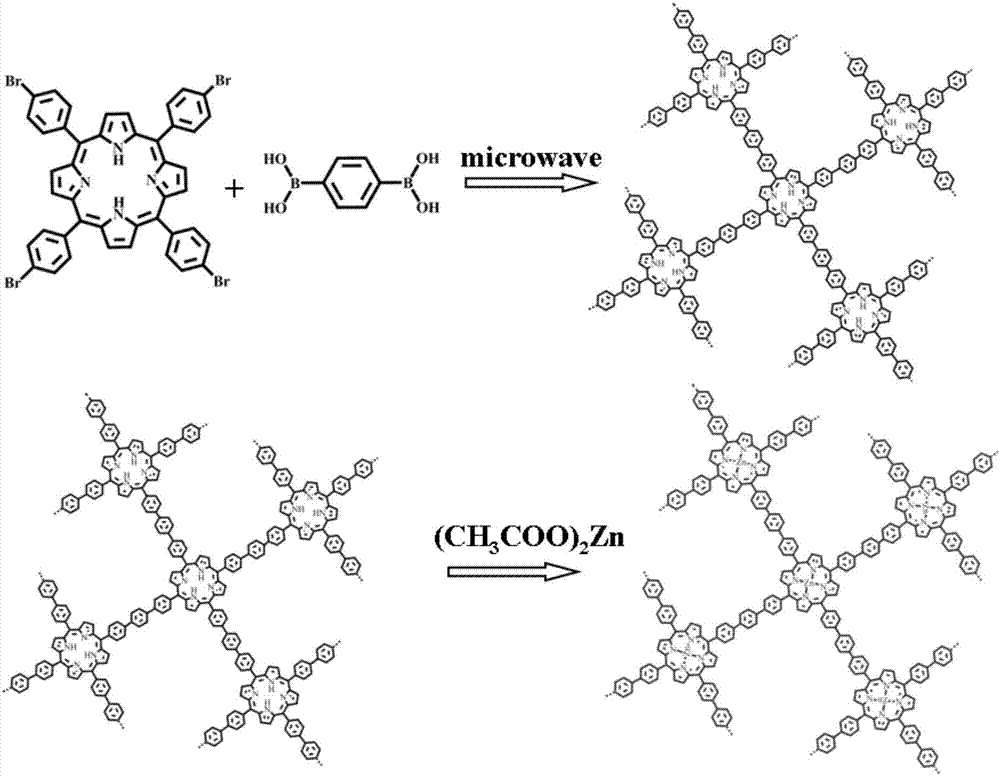

[0047] S11: Synthesis of porphyrin-conjugated microporous organic polymers (such as figure 1 shown):

[0048] Tetrabromophenylporphyrin (186.10mg, 0.1mmol), terephthalic acid (33.15mg, 0.2mmol), and 8ml of 1,4-dioxane were added to the flask, mixed evenly by ultrasonication, frozen-pump- Thaw cycle three times to remove oxygen and add K 2 CO 3 Solution 2.0ml (110.4mg, 0.8mmol) and catalyst Pd (PPh 3 ) 4 (11.6mg, 10μmol), put it in a microwave oven, freeze-pump-thaw cycle three times, the stirring speed is 800rpm, under the protection of nitrogen, under the optimal conditions, select the microwave power of 100w, the reaction temperature is 90℃, the reaction time is 90min, the reaction is over Afterwards, the reaction solution was filtered with suction, and the p...

Embodiment 2

[0059] Identification of Volatile Aroma Substances in Chinese Zanthoxylum bungeanum in Example 2

[0060] (1) Sample processing method: Grind the Zanthoxylum bungeanum sample, sieve it, weigh 200 mg of the sample in 20 ml of solid-phase microextraction headspace product, equilibrate in a water bath at 60 ° C for 30 minutes, and mix the solid-phase microextraction prepared in Example 1 Insert the head into the headspace bottle, extract for 30min, and finally keep the quartz fiber in the gas chromatography inlet for 3min. Figure 4 It is a schematic diagram of solid phase microextraction coating preparation and extraction process.

[0061] (2) Gas chromatography conditions for Zanthoxylum bungeanum: carrier gas: He gas, column flow rate, 1mL / min; sampling method: split flow; split ratio: 5:1; chromatographic column: Agilent DB-5MS (30m×0.25mm×0.25μm) ;Injection port temperature: 200°C; temperature program: 60°C without holding, 2°C / min up to 85°C without hold, 8°C / min up to 200...

Embodiment 3

[0065] Identification of volatile aroma substances in the bay leaf of embodiment 3

[0066] (1) Sample processing method: Grind and sieve the bay leaf sample, weigh 200 mg of the sample into 20 ml of solid-phase microextraction headspace product, equilibrate in a 60°C water bath for 30 minutes, and mix the solid-phase microextraction prepared in Example 1 Insert the extraction head into the headspace bottle, extract for 30 minutes, and finally keep the fiber in the gas chromatography inlet for 3 minutes.

[0067] (2) Germ leaf gas chromatography conditions: carrier gas: He; column flow rate, 1mL / min; sample injection method: split flow; split ratio: 5:1; chromatographic column: Agilent DB-5MS (30m×0.25mm×0.25μm) ;Injection port temperature: 200°C; Temperature program: 60°C not maintained, 2°C / min to 90°C, 5°C / min to 200°C, 10°C / min to 220°C and hold for 2min; Transfer line temperature, 250 ℃.

[0068] Mass spectrometry conditions: quadrupole; scanning method: SCAN; scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com