Concrete wall and preparation method thereof

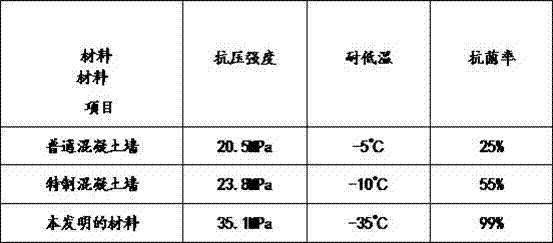

A technology of concrete walls and parts by weight, applied to walls, building components, buildings, etc., can solve the problems of low temperature resistance of walls, low structural strength, complicated preparation process, etc., and achieve good low temperature resistance and high structural strength , The effect of fewer manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A concrete wall, made of the following materials in parts by weight, including 15 parts of gravel, 58 parts of pozzolan cement, 16 parts of ground slag powder, 2 parts of quartz sand, 7 parts of magnesium oxide, 25 parts of sodium sulfite, nano 8 parts of silver, 9 parts of ammonium dihydrogen phosphate, 23 parts of steel fiber, 2 parts of dibutyl sebacate, 8 parts of diphenylsilanediol, 6 parts of resorcinol, 8 parts of sodium aminotrimethylene phosphonate, 3 parts of polyoxyethylene alkanolamide, 10 parts of sodium fluoride, 5 parts of tributyltin, 6 parts of lithium carbonate, 8 parts of pentaerythritol phosphate, 3 parts of polyimide and 14 parts of polyvinyl alcohol.

[0019] A method for preparing a concrete wall, comprising the steps of:

[0020] 1) Put 15 parts of gravel, 58 parts of pozzolan cement, 16 parts of ground slag powder, 2 parts of quartz sand, 7 parts of magnesium oxide, 25 parts of sodium sulfite, 8 parts of nano-silver, and 9 parts of ammonium dihy...

Embodiment 2

[0025] A concrete wall, made of the following materials in parts by weight, including 17.5 parts of gravel, 59 parts of pozzolan cement, 19 parts of ground slag powder, 3.5 parts of quartz sand, 12 parts of magnesium oxide, 27.5 parts of sodium sulfite, nano 12 parts of silver, 11.5 parts of ammonium dihydrogen phosphate, 24 parts of steel fiber, 3.5 parts of dibutyl sebacate, 9 parts of diphenylsilanediol, 8 parts of resorcinol, 8-15 parts of sodium aminotrimethylene phosphonate 3-8 parts of polyoxyethylene alkyl alcohol amide, 10-15 parts of sodium fluoride, 6.5 parts of tributyltin, 6.5 parts of lithium carbonate, 10 parts of pentaerythritol phosphate, 6 parts of polyimide and 16 parts of polyvinyl alcohol .

[0026] A method for preparing a concrete wall, comprising the steps of:

[0027] 1) Put 17.5 parts of gravel, 59 parts of pozzolan cement, 19 parts of finely ground slag powder, 3.5 parts of quartz sand, 12 parts of magnesium oxide, 27.5 parts of sodium sulfite, 12 p...

Embodiment 3

[0032]A concrete wall is made of the following materials in parts by weight, including 20 parts of gravel, 60 parts of pozzolan cement, 22 parts of ground slag powder, 5 parts of quartz sand, 17 parts of magnesium oxide, 30 parts of sodium sulfite, nano 16 parts of silver, 14 parts of ammonium dihydrogen phosphate, 25 parts of steel fiber, 7 parts of dibutyl sebacate, 10 parts of diphenylsilanediol, 10 parts of resorcinol, 15 parts of sodium aminotrimethylene phosphonate, 8 parts of polyoxyethylene alkanolamide, 15 parts of sodium fluoride, 8 parts of tributyltin, 7 parts of lithium carbonate, 12 parts of pentaerythritol phosphate, 9 parts of polyimide and 18 parts of polyvinyl alcohol.

[0033] A method for preparing a concrete wall, comprising the steps of:

[0034] 1) Put 20 parts of gravel, 60 parts of pozzolan cement, 22 parts of ground slag powder, 5 parts of quartz sand, 17 parts of magnesium oxide, 30 parts of sodium sulfite, 16 parts of nano silver, and 14 parts of am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com