A method of coupling electric field and microwave to strengthen seaweed anaerobic fermentation to produce methane

A technology for anaerobic fermentation and methane production, applied in fermentation, waste fuel and other directions, can solve problems such as environmental pollution and energy loss, and achieve the effects of improving operation stability, stabilizing gas production, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

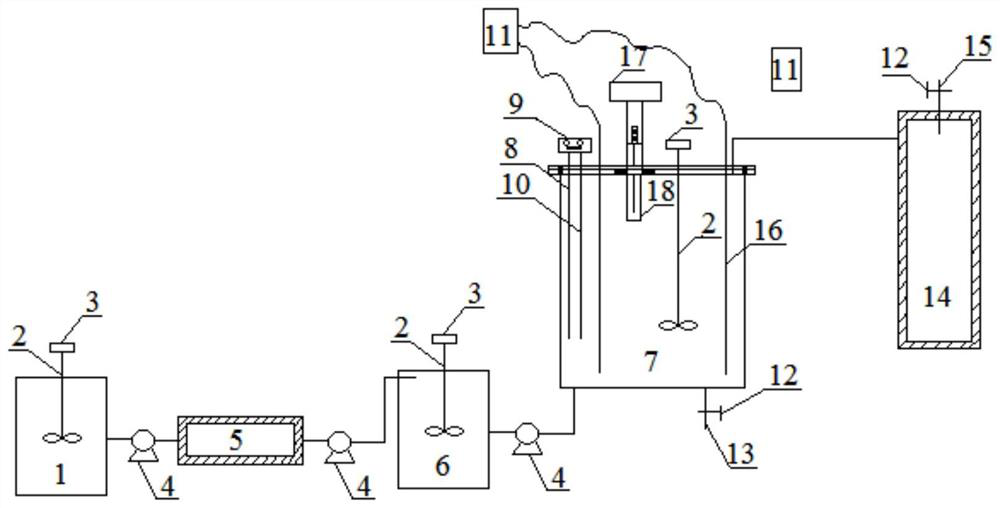

Image

Examples

Embodiment 1

[0033] The method for producing methane by electric field and microwave coupling enhanced anaerobic fermentation of seaweed provided in this embodiment comprises the following steps:

[0034] (1) Seaweed (kelp, seaweed) is naturally air-dried and dried to constant weight, then crushed to 2mm, and water is added, and the solid-to-liquid ratio is 1:20.

[0035] (2) Then, the pretreatment of the mixed seaweed liquid is carried out by microwave pretreatment first, followed by heating pretreatment.

[0036] Microwave pretreatment adopts microwave radiation power of 850W, frequency of 2450MHz, and processing time of 85min.

[0037] Microwave pretreatment followed by heating pretreatment. The heat treatment temperature is 150°C, and the treatment time is 150min.

[0038] (3) Anaerobic fermentation stage. The seaweed is input into the anaerobic fermentation tank from the pretreatment tank, and the seaweed content in the anaerobic fermentation tank 7 is stable at 75% of the tank volum...

Embodiment 2

[0049] The method for producing methane by electric field and microwave coupling enhanced anaerobic fermentation of seaweed provided in this embodiment comprises the following steps:

[0050] (1) Seaweed (Sargassum, Enteromorpha) were naturally air-dried and dried to constant weight, then crushed to 40mm, and a phosphoric acid solution with a concentration of 0.5% by mass was added, and the mixing ratio was 1:15.

[0051] (2) Pretreatment of the mixed seaweed liquid is performed firstly by microwave pretreatment, and then by heating pretreatment.

[0052] The microwave pretreatment adopts microwave radiation power of 150W, frequency of 2450MH, and processing time of 10min.

[0053] Microwave pretreatment followed by heating pretreatment. The heat treatment temperature is 50°C, and the treatment time is 100min.

[0054] (3) Anaerobic fermentation stage. The seaweed is input from the pretreatment tank into the anaerobic fermentation tank, and the seaweed content in the fermen...

Embodiment 3

[0060] The method for producing methane by electric field and microwave coupling enhanced anaerobic fermentation of seaweed provided in this embodiment comprises the following steps:

[0061] (1) Seaweed (Sargassum) was naturally air-dried and dried to constant weight, then crushed to 25 mm, and sludge with a mass moisture content of 80% was added, and the mixing ratio was 1:10.

[0062] (2) Pretreatment of the mixed solution is carried out firstly by microwave pretreatment, and then by heating pretreatment. The microwave pretreatment adopts a microwave radiation power of 180W, a microwave frequency of 2450MHz, and a processing time of 100min.

[0063] Microwave pretreatment followed by heating pretreatment. The heat treatment temperature is 100°C, and the treatment time is 50 minutes.

[0064] (3) Anaerobic fermentation stage. The seaweed is input from the pretreatment tank into the anaerobic fermentation tank, and the seaweed content in the fermentation tank is stabilized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com