Vertical orientation strong magnetic dielectric film and preparation method thereof

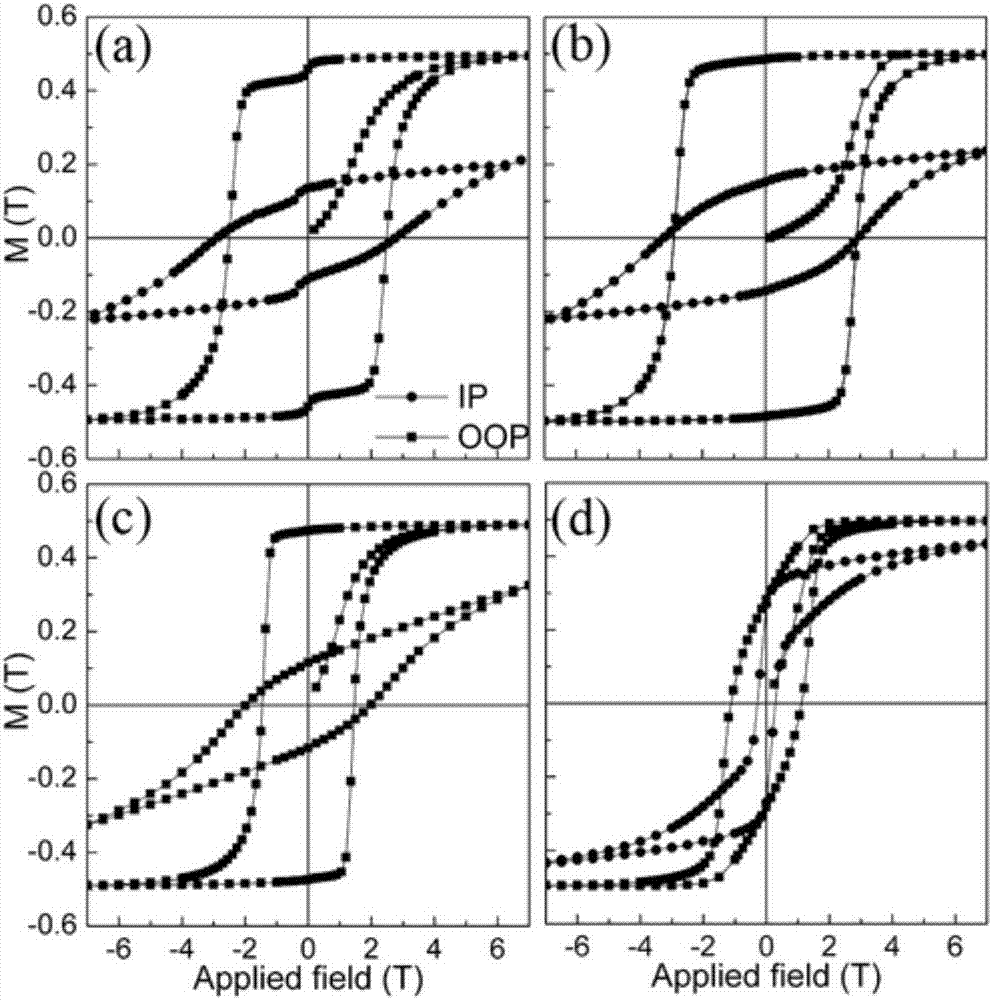

A technology of vertical orientation and dielectric thin film, applied in the application of magnetic film to substrate, magnetic layer, inductor/transformer/magnet manufacturing, etc. High substrate cost and other issues, to achieve the effect of small grain size, small volume and large coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preparation method of the above-mentioned vertical orientation ferromagnetic thin film, comprising the steps of: (1) cleaning and drying the thermally oxidized Si substrate;

[0024] (2) Under vacuum conditions, the AlN buffer layer was prepared on the surface of thermally oxidized Si substrate by radio frequency reactive sputtering, and the atmosphere in the sputtering chamber was 0.05-50Pa N 2 and 0.05-50Pa Ar mixed atmosphere, the target material is an Al target with a purity higher than 99.99%, the temperature is 100°C, and the thickness of the AlN buffer layer is 1-100nm;

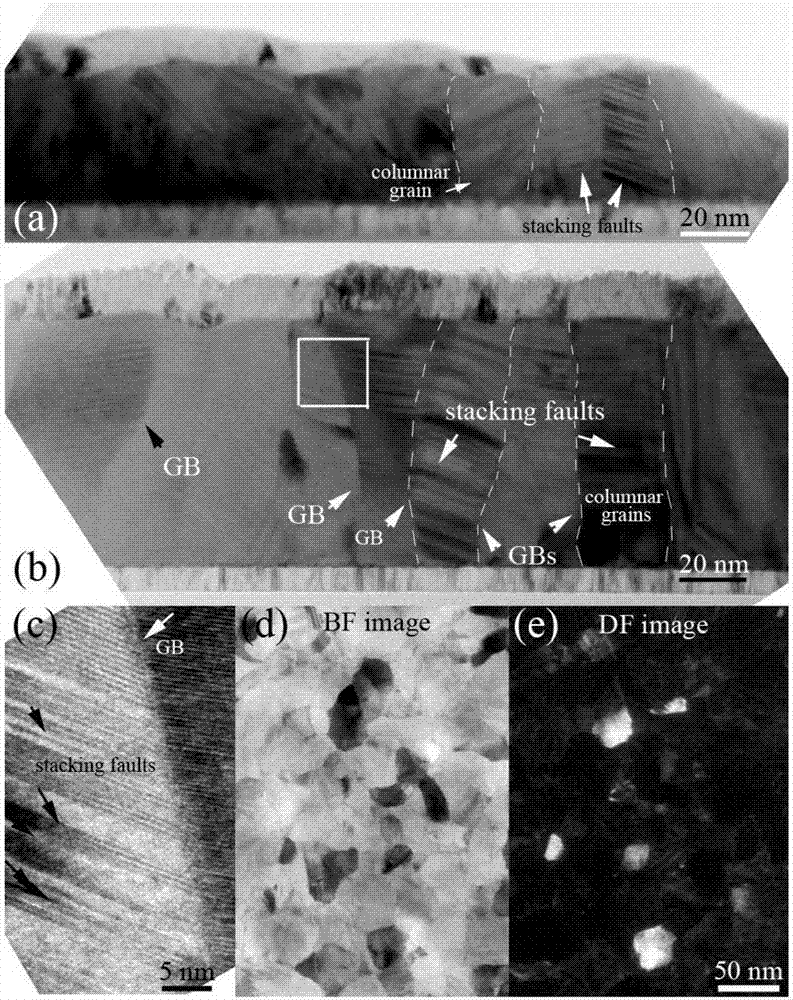

[0025] (3) Under vacuum conditions, the magnetron sputtering method is used to prepare a vertically oriented ferromagnetic layer on the surface of the AlN buffer layer. The composition of the vertically oriented ferromagnetic layer is SmCo 3.5 Cu 0.5 , the atmosphere is 0.05-50Pa Ar gas with a purity higher than 99.9%, the temperature is 350°C, the deposition time is determined according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com