A method for improving the optical properties of silica through surface crystallization

A technology of silicon dioxide and optical properties, which is used in devices for coating liquids on surfaces, special surfaces, pretreated surfaces, etc. It can solve the problems of strict equipment requirements, high cost, and difficulty in industrialized production, and achieve low production costs. , The effect of short production cycle and improved light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

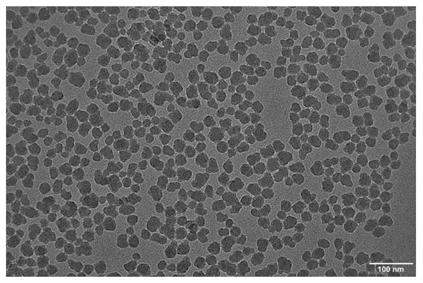

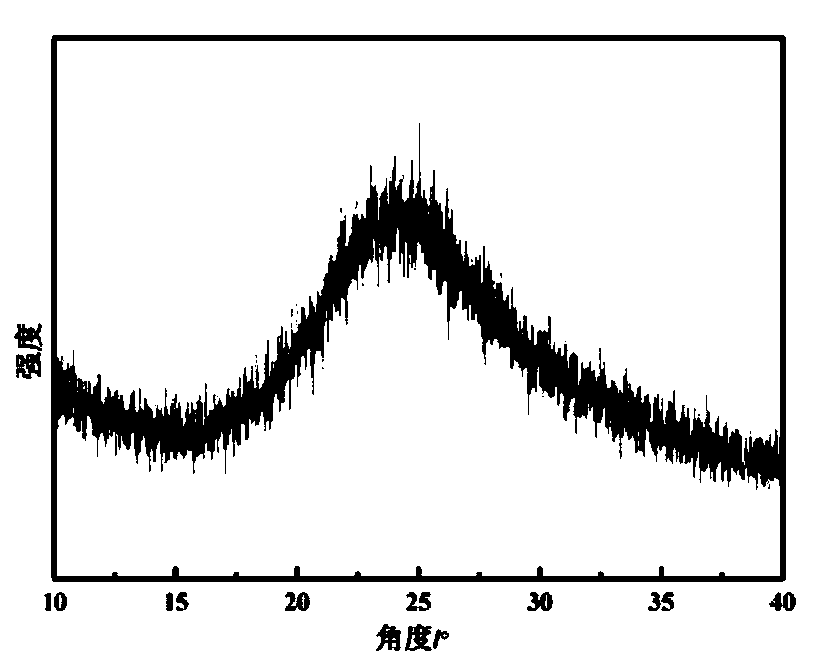

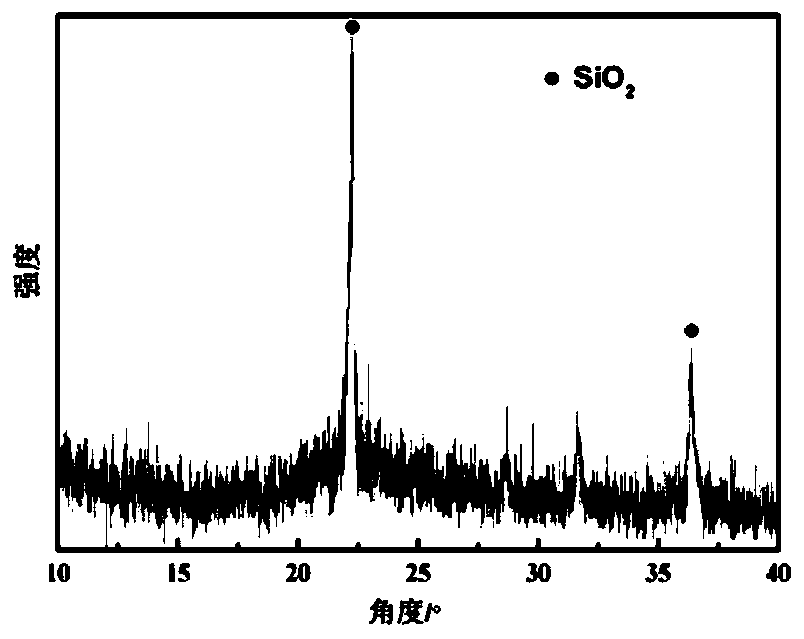

[0032] The nano-silica sol particles are chemically modified with polyethylene glycol, and the sol is uniformly coated on the silicon wafer. Place the silicon wafer coated with silicon dioxide particles in a crucible and heat-treat in a furnace. The heat-treatment temperature is 1200°C, the atmosphere in the furnace is argon, the gas pressure is 4MPa, the heat-treatment time is 5h, and the heating rate of the heat-treatment is 10 °C / min, the cooling rate is 10 °C / min, and a uniform silicon dioxide film layer crystallized on the particle surface is obtained.

Embodiment 2

[0034] The nano-silica sol particles are chemically modified with polyethylene glycol, and the sol is uniformly coated on the silicon wafer. Place the silicon wafer coated with silicon dioxide particles in a crucible and heat-treat in a furnace. The heat-treatment temperature is 1200°C, the atmosphere in the furnace is argon, the gas pressure is 4MPa, the heat-treatment time is 1h, and the heating rate of heat-treatment is 10 °C / min, the cooling rate is 10 °C / min, and a uniform silicon dioxide film layer crystallized on the particle surface is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com