A kind of preparation method of izm-2 molecular sieve

A technology of molecular sieves and cations, applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve the problems of zeolite molecular sieve agglomeration, etc., and achieve the improvement of particle aggregation, selectivity and isomer yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of IZM-2 molecular sieve sample

[0027] Add 0.202g of aluminum isopropoxide, 1.58g of sodium hydroxide, and 23.34g of silica sol to 70g of deionized water in sequence, stir evenly, and add 5.29g of template agent (1,6-dimethylpiperidine hexane) to the above mixed solution In, stir well until gelled. The reaction mixture was put into a polytetrafluoroethylene-lined stainless steel reactor, crystallized at 170°C for 7 days, the reaction product was washed 3 times with deionized water, then washed 3 times with ethanol solution, and dried at 80°C More than 12h, the final product is obtained. The chemical molar ratio of each component in the reaction system is as follows: 60SiO 2 : 0.25Al 2 o 3 : 10Na 2 O: 10R: 2000H 2 O. wherein R refers to 1,6-dimethylpiperidine hexane.

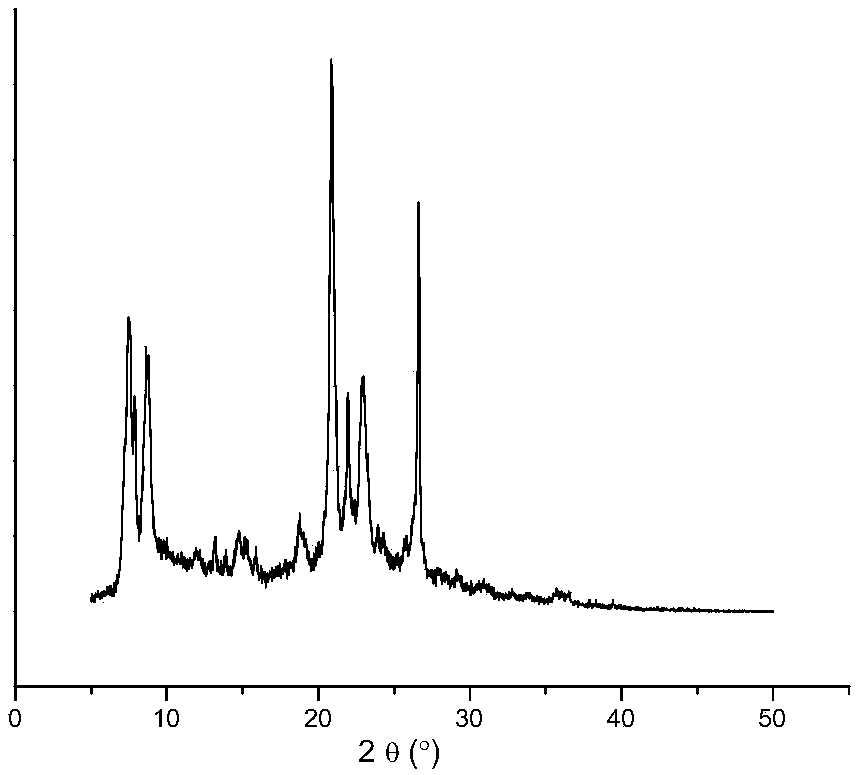

[0028] attached figure 1 The XRD characterization results of the IZM-2 molecular sieve prepared for Example 1.

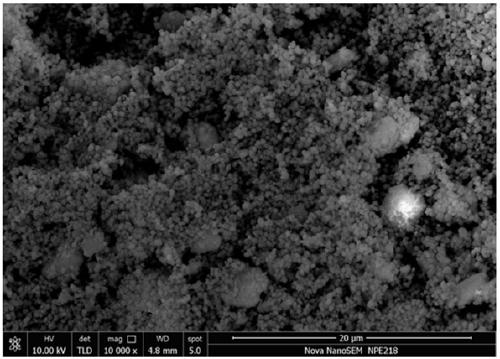

[0029] attached figure 2 Scanning electron micro...

Embodiment 2

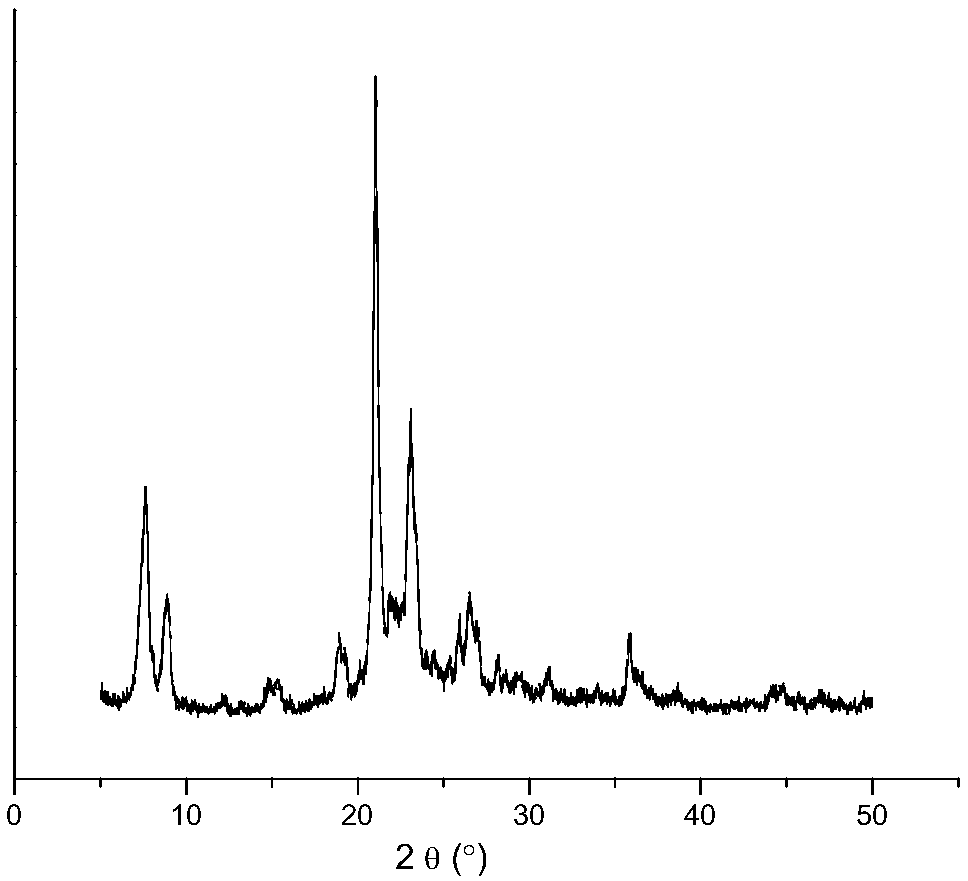

[0030] Embodiment 2: add CTAC cationic surfactant to prepare IZM-2 molecular sieve

[0031] Add 0.202g of aluminum isopropoxide, 1.58g of sodium hydroxide, 23.34g of silica sol, and 5.29g of templating agent (1,6-dimethylpiperidine hexane) into 70g of deionized water in sequence, stir well, and then add 1.87g Cetyltrimethylammonium chloride was added to the above mixed solution until the mixture was evenly stirred to form a gel. The reaction mixture was put into a polytetrafluoroethylene-lined stainless steel reactor, crystallized at 170°C for 7 days, the reaction product was washed 3 times with deionized water, and washed 3 times with ethanol solution, and heated at 80°C After drying for more than 12 hours, the final product is obtained. The chemical molar ratio of each component in the reaction system is as follows: 60SiO 2 : 0.25Al 2 o 3 : 10Na 2 O: 10R: 2000H 2 O: 0.05CTAC, wherein R is the templating agent 1,6-dimethylpiperidine hexane, and CTAC is the cationic surf...

Embodiment 3

[0036] Embodiment 3: the catalytic performance evaluation of the prepared IZM-2 molecular sieve

[0037] The hydroisomerization reaction of n-dodecane was used as a model to evaluate the catalytic performance of the prepared IZM-2 molecular sieve as a catalyst carrier. The catalyst in this reaction was 0.5wt% Pt / IZM-2. The reaction is carried out in a micro-fixed-bed reactor with stainless steel tubes at atmospheric pressure. The inner diameter of the reaction tube is 10mm, and the loading amount of the catalyst is 3g (20-40 mesh). Mix evenly and fill in the middle of the reaction tube. Both ends of the catalyst bed are filled with 20-40 mesh quartz sand, WHSV=1-1 , reaction pressure P=4.5Mpa, n(H 2 ) / n(n-C12)=15(mol / mol), H 2 The gas flow rate is 98.5ml / min, and the reaction is sampled every hour, and the sample of the third hour at each temperature point is analyzed by gas chromatography. The conversion rate of n-dodecane was controlled by changing the reaction temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com