Lithium-sulfur battery composite positive electrode and preparation method thereof

A composite positive electrode and lithium-sulfur battery technology, applied in the field of electrochemical batteries, can solve the problems of reducing the relative content of active material sulfur, low battery capacity retention rate, increase of binders and conductive agents, etc., to achieve enhanced electronic conductivity, The effect of maintaining structural stability, improving specific capacity and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

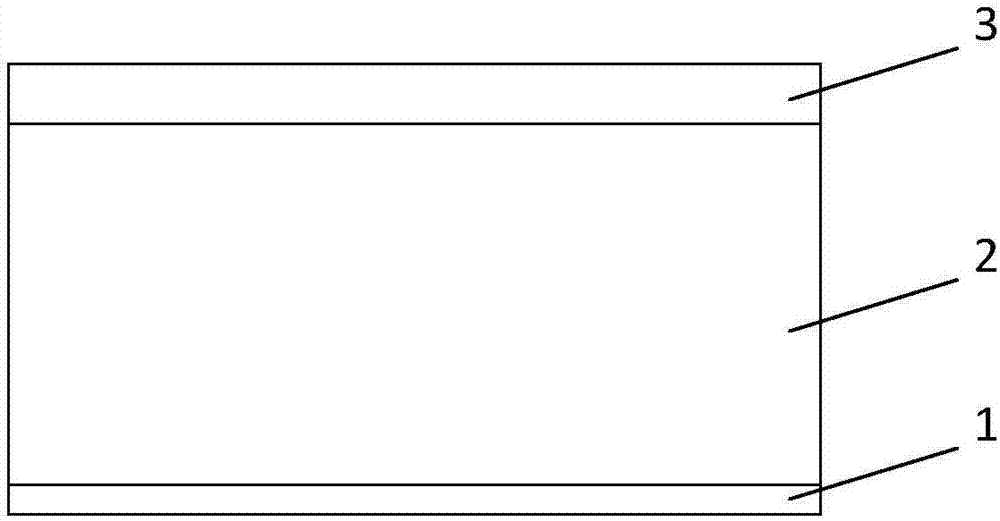

[0032] The positive electrode modification and preparation method of the lithium-sulfur battery of the present invention mainly includes the following steps:

[0033] Step 1, preparation of ferroelectric material and graphene mixed spray coating.

[0034] Disperse graphene in NMP so that the concentration of graphene is 1mg / ml-3mg / ml, sonicate for 0.5h, then add ferroelectric material to make the concentration of ferroelectric material 0.5mg / ml-3mg / ml, stir for 0.5 h and ultrasonication for 0.5h to obtain a uniformly dispersed mixed solution; then place the resulting solution in a spray gun in a nitrogen-filled glove box, and then spray the mixed solution on an alcohol-cleaned aluminum foil to keep the thickness of the mixed material at 0.2μm-5μm, finally dry the sprayed aluminum foil in a vacuum oven at 60°C for 12h-24h.

[0035] Step 2, preparation of carbon / sulfur slurry scrape coating:

[0036]Method 1: Weigh 70mg of nano-sulfur, 20mg of conductive carbon black (Super P)...

Embodiment 1

[0041] Graphene is dispersed in NMP, makes the concentration of graphene 1mg / ml, ultrasonic 0.5h, adds the potassium niobate (KNbO 3 ), so that KNbO 3 The concentration is 2mg / ml, stirred for 0.5h and ultrasonicated for 0.5h to obtain a uniformly dispersed mixed solution; then the resulting solution was placed in a spray gun in a glove box filled with nitrogen, and then the mixed solution was sprayed on an alcohol-cleaned aluminum foil Keep the thickness of the mixed material at 2 μm, and finally dry the sprayed aluminum foil in a vacuum oven at 60° C. for 18 hours.

[0042] Weighed 105 mg of nano-sulfur, 30 mg of conductive carbon black (Super P) and 15 mg of polyvinylidene fluoride (PVDF) at a mass ratio of 7:2:1, and ground them in a mortar for 0.5 h. First, PVDF was added to 0.5 mg N-methylpyrrolidone (NMP) solution, and stirred magnetically for 6 h; then, adding ground nano-sulfur particles, stirring for 0.5 h, and ultrasonication for 1 h (ultrasonic power 300 W), and fi...

Embodiment 2

[0046] Graphene is dispersed in NMP, makes the concentration of graphene 2mg / ml, ultrasonic 0.5h, adds the barium titanate (BaTiO 3 ), making BaTiO 3 The concentration is 1mg / ml, stirred for 0.5h and ultrasonicated for 0.5h to obtain a uniformly dispersed mixed solution; then the resulting solution was placed in a spray gun in a glove box filled with nitrogen, and then the mixed solution was sprayed on an alcohol-cleaned aluminum foil Keep the thickness of the mixed material at 1.5 μm, and finally dry the sprayed aluminum foil in a vacuum oven at 60° C. for 20 h.

[0047] Weigh 105mg of nano-sulfur, 30mg of conductive carbon black (Super P), and 15mg of polyvinylidene fluoride (PVDF) at a mass ratio of 7:2:1, mix the weighed materials into a mortar, and grind for 1 hour to obtain a mixed Homogeneous positive electrode material; then, put the mixed material into a hydrothermal kettle in a nitrogen-filled glove box, and transfer the hydrothermal kettle to a tube furnace filled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com