Preparation method of natural spice gamma decalactone

A technology of natural flavor and decolactone, which is applied in the fields of materials science and biological fermentation engineering, can solve the problems of lower utilization rate of yeast to substrates, increased one-time investment cost of γ-decalactone, unfavorable yeast cell activity, etc. Improve product formation rate, good industrial application prospects, and increase the effect of one-time accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Control experiment

Embodiment 2

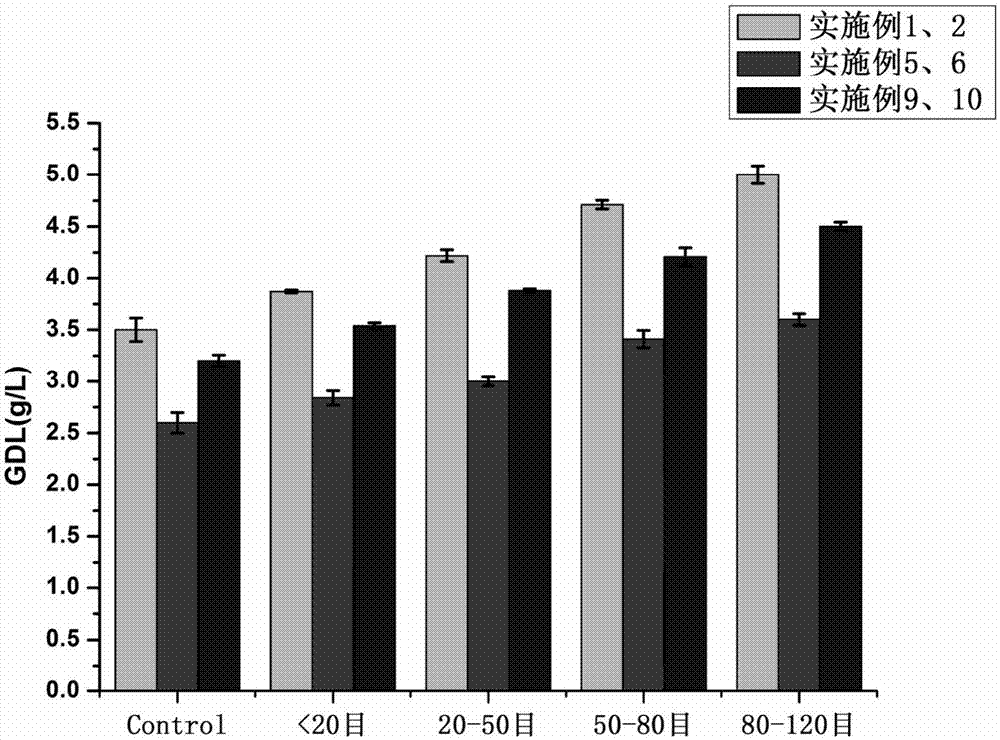

[0031] Example 2 The effect of substrate embedding on the conversion of γ-decalactone

[0032]Treatment of modified fiber materials: crush the modified fiber (purchased from Shanghai Guyang Industrial Co., Ltd., model: GY131) with a pulverizer, use 20, 50, 80, and 120 mesh sieves to screen the fibers, and filter <20 mesh, 20- 50 mesh, 50-80 mesh, and 80-120 mesh fiber particles were screened out; embedding: Mix the screened modified fibers with different meshes and ricinoleic acid at a mass ratio of 1:1, and bathe in water at 50°C for 1 hour. And keep stirring; transformation medium preparation: Magnesium sulfate heptahydrate 10g / L, dipotassium hydrogen phosphate 10g / L, glycerol 15g / L, L-carnitine 0.12g / L, pH is 6.4, put the culture medium into 250ml shake In the bottle, the amount of liquid is 50ml; the addition of embeddings: based on ricinoleic acid 40g / L, the amount of embeddings is 4g; sterilization: 121°C, damp heat sterilization for 15min; inoculation: after the bacteri...

Embodiment 3

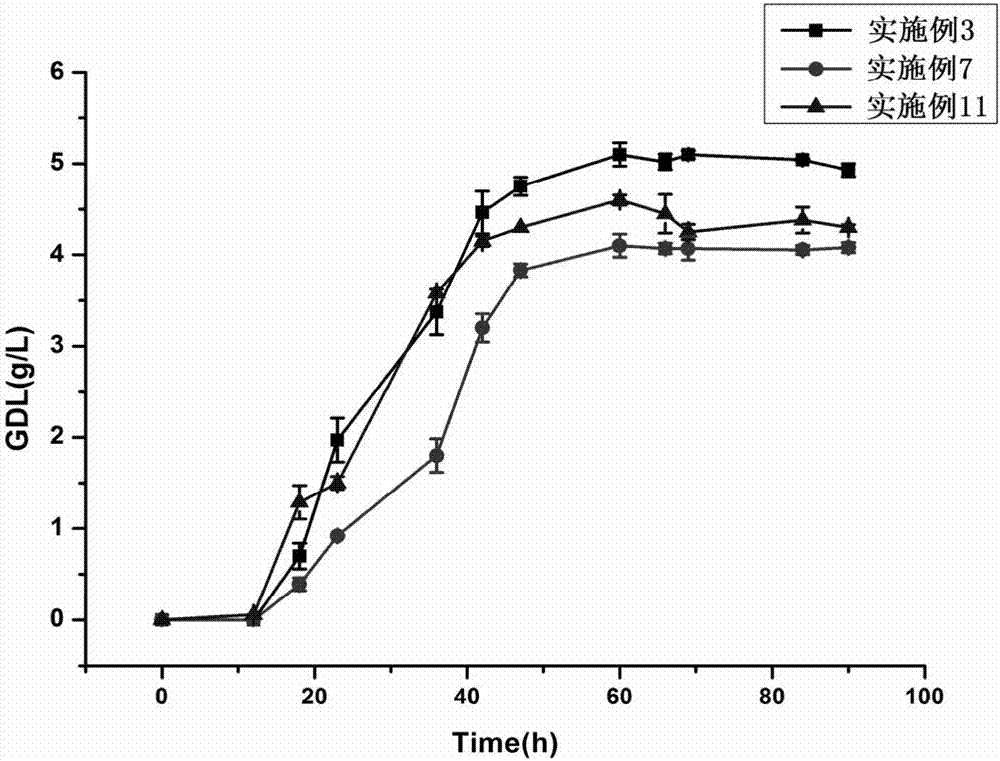

[0033] Example 3 Biological Fermentation Tank Transformation Control Experiment

[0034] Preparation of transformation medium: ricinoleic acid 40g / L, magnesium sulfate heptahydrate 10g / L, dipotassium hydrogen phosphate 10g / L, glycerin 15g / L, L-carnitine 0.12g / L, pH 6.4, 5L canned liquid Amount of 3L; Sterilization: 121 ℃, damp heat sterilization for 15min; Inoculation: After sterilization and cooling, according to the yeast powder 15g / L, weigh high-activity yeast powder (purchased from Angel Yeast Co., Ltd. Company, model: food grade) 45g, and put it into a fermenter; transformation culture: stirring speed 400r / min, temperature 28°C, ventilation volume 4.0v ▪v -1 ▪ m -1 , the conversion time was 90 hours, and the fermentation broth containing γ-decalactone was obtained; detection: when sampling, increase the speed to 600 r / min, take 10ml with a pipette, add three times the volume of absolute ethanol, and shake well , sampled and processed for detection by gas chromatography ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com