Method for regulating acidogenic effect of liquid state fermentation of sludge and removing nitrogen and phosphorus on line

A technology of nitrogen and phosphorus removal and liquid fermentation, applied in the field of organic solid waste recycling, can solve the problem of long overall cycle of sludge anaerobic fermentation and nitrogen and phosphorus removal, increase of subsequent treatment steps of fermentation broth, unfavorable process operation and management and other problems, to achieve the effect of simplifying the process flow, reducing the subsequent treatment process and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

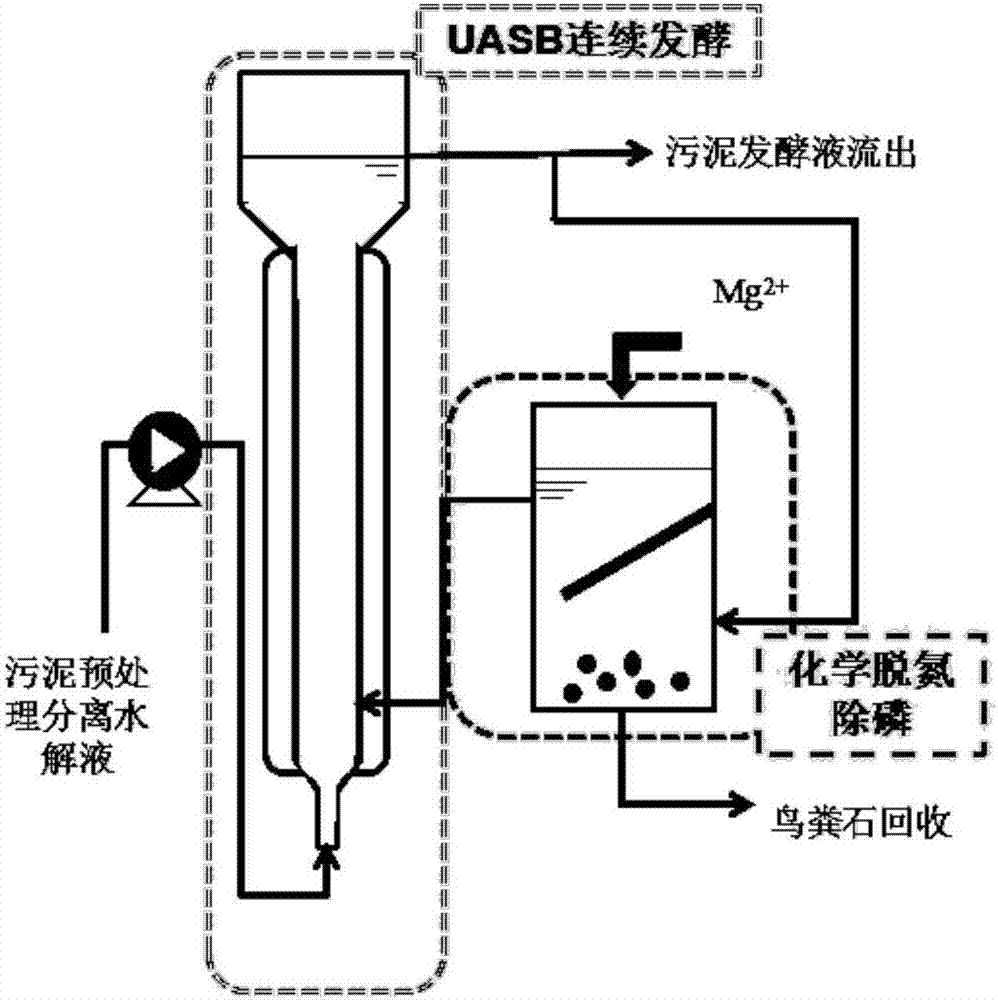

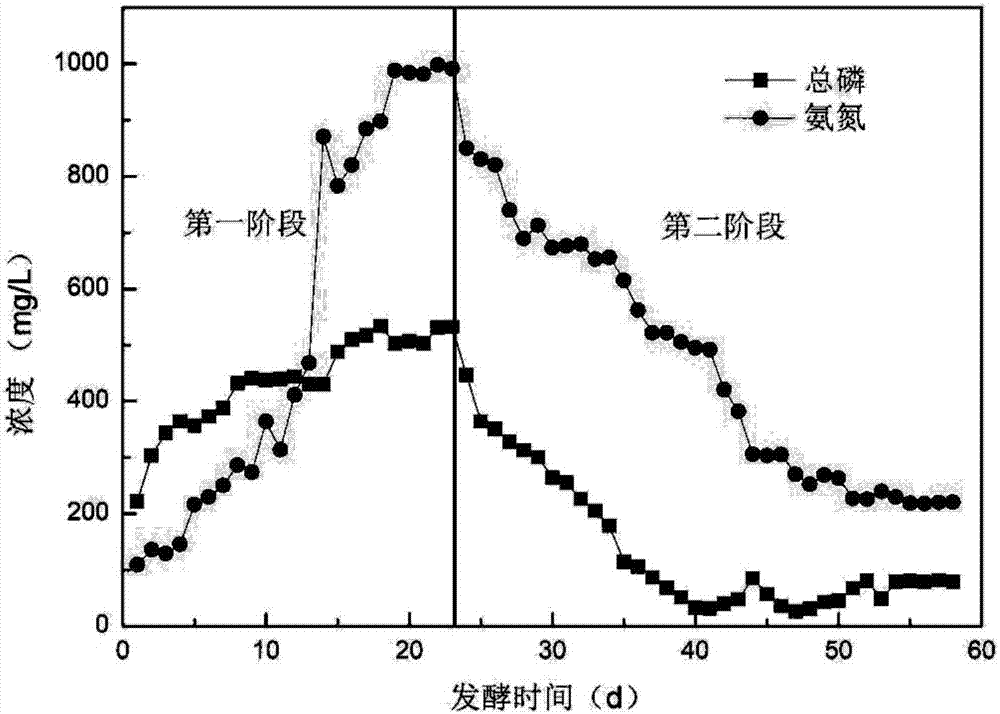

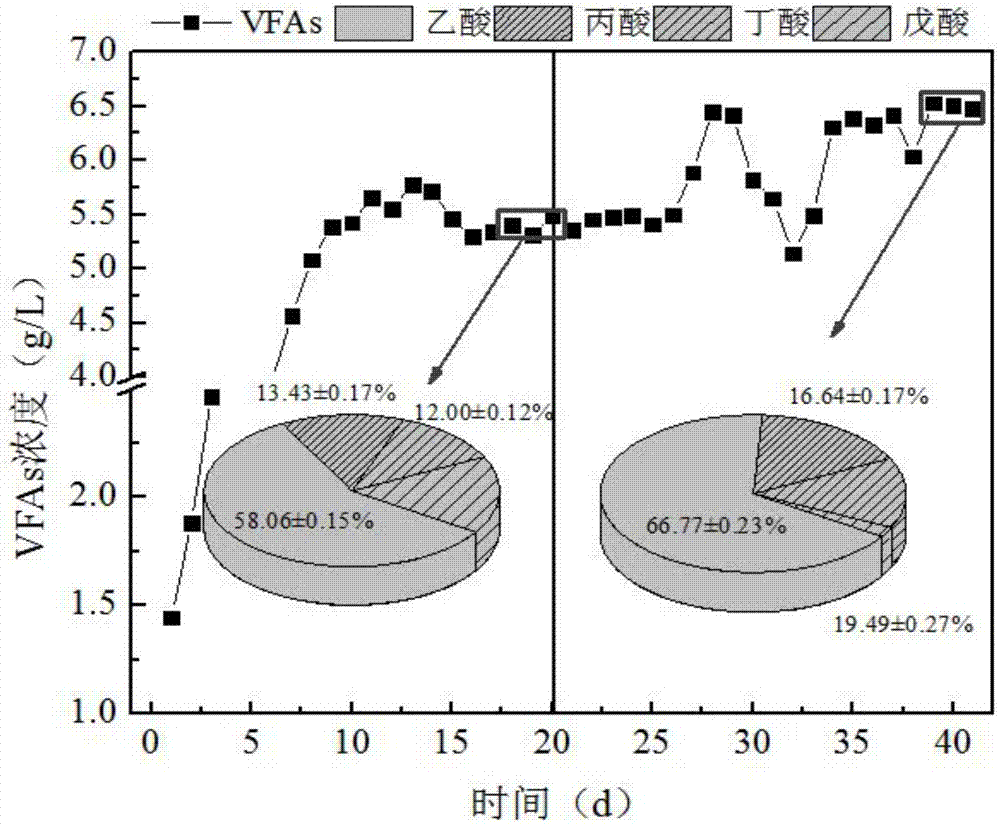

[0030] (1) The first stage (UASB liquid fermentation without adding nitrogen and phosphorus removal device): Use deionized water to adjust the total solid concentration (TS) of the remaining sludge (Wuxi Shuofang Wastewater Treatment Plant, Jiangsu) to 75g / L, and use The pH of the NaOH solution was adjusted to 12, and after sealing, it was placed at 90-105°C and stirred slowly for 12 hours for pretreatment. Centrifuge the pretreated hydrolysate, and separate the liquid (organic load is 8kg COD / m 3 / d) Continuously pass into a 5L UASB reactor (the volume of the inoculated seed mud is 20%) for fermentation. During the fermentation, the temperature in the reactor is controlled at 35±2℃ and the pH is controlled at 9-10. The yield of ammonia nitrogen, total phosphorus and TVFA are as follows: figure 2 , 3 Shown in the first stage. During steady operation, the concentrations of ammonia nitrogen and total phosphorus were 991.60±3.23 mg / L and 532.16±1.59 mg / L, respectively, and the yi...

Embodiment 2

[0033] UASB liquid fermentation with nitrogen and phosphorus removal equipment:

[0034] Adjust the total solid concentration (TS) of the remaining sludge (Wuxi Shuofang Wastewater Treatment Plant, Jiangsu) to 75g / L with deionized water, and adjust its pH to 12 with NaOH solution, and then place it under 95℃ and slowly stir for 12h after sealing. Pretreatment. Centrifuge the pretreated hydrolysate, and separate the liquid (organic load is 8kg COD / m 3 / d) Continuously pass into a 5L UASB reactor (the volume of the inoculated seed mud is 20%) for fermentation. During the fermentation, the temperature in the reactor is controlled at 35±2°C, and the pH is controlled at 9-10. Among them, the fermentation broth of UASB enters the nitrogen and phosphorus removal device with a reflux ratio of 0.8 and HRT of 2.0h, and Mg is kept in the nitrogen and phosphorus removal device. 2+ Dosing concentration is 1000±5.0mg / L, temperature and pH are the same as UASB. During steady operation, the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com