Pavement brick prepared by recycling building materials, and preparation method thereof

A technology for building materials and pavement bricks, which is applied in the direction of paving, construction, and application of prefabricated blocks, which can solve the problems of non-recycling of waste, no resistance to ultraviolet radiation, and low flexural strength, so as to reduce the urban heat island. Degree of effect, effect of increasing structural stability, good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

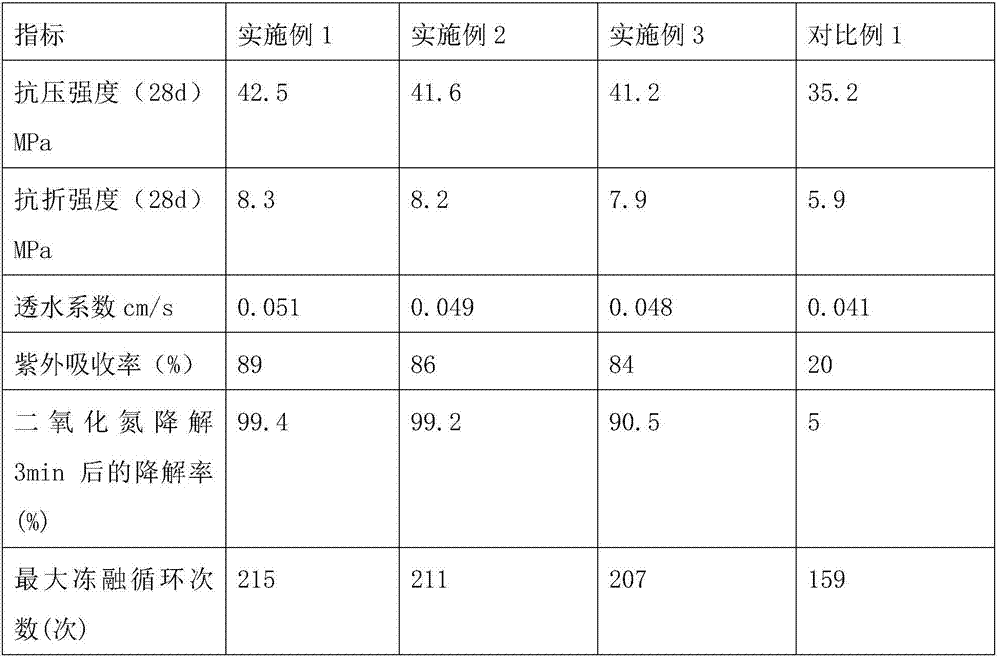

Examples

Embodiment 1

[0037] A pavement brick for recycled building materials, comprising the following raw materials in parts by weight: 22.5 parts of cement, 17.5 parts of construction waste fine aggregate, 8 parts of construction waste coarse aggregate, 2 parts of aggregate modifier, and 4.5 parts of nano silicon dioxide 3.5 parts of titanium dioxide, 12.5 parts of steel slag, 6 parts of polyamide, 0.35 parts of water reducer, 1.5 parts of antifreeze, 0.4 parts of pigment powder and 5 parts of water.

[0038] Nano-silica is added to the raw material of pavement bricks, because it has conventional SiO 2 The special optical properties that it does not have, it has extremely strong ultraviolet absorption and heat radiation absorption characteristics, and its absorption rate of ultraviolet light within a wavelength of 400nm is as high as 70%, so adding it to the aggregate of pavement bricks can achieve anti-ultraviolet The purpose of radiation and thermal aging can reduce the degree of urban heat is...

Embodiment 2

[0052] A pavement brick for recycled building materials, comprising the following raw materials in parts by weight: 20 parts of cement, 15 parts of construction waste fine aggregate, 6 parts of construction waste coarse aggregate, 0.5 part of aggregate modifier, and 3 parts of nano-silica 2 parts of titanium dioxide, 10 parts of steel slag, 5 parts of polyamide, 0.2 parts of water reducer, 0.5 parts of antifreeze, 0.3 parts of pigment powder and 4 parts of water.

[0053] Nano-silica is added to the raw material of pavement bricks, because it has conventional SiO 2 The special optical properties that it does not have, it has extremely strong ultraviolet absorption and heat radiation absorption characteristics, and its absorption rate of ultraviolet light within a wavelength of 400nm is as high as 70%, so adding it to the aggregate of pavement bricks can achieve anti-ultraviolet The purpose of radiation and thermal aging can reduce the degree of urban heat island effect in summ...

Embodiment 3

[0066] A pavement brick for recycling building materials, comprising the following raw materials in parts by weight: 25 parts of cement, 20 parts of construction waste fine aggregate, 10 parts of construction waste coarse aggregate, 1.5 parts of aggregate modifier, 6 parts of nano silicon dioxide 5 parts of titanium dioxide, 15 parts of steel slag, 7 parts of polyamide, 0.5 parts of water reducer, 2.5 parts of antifreeze, 0.5 parts of pigment powder and 6 parts of water.

[0067] Nano-silica is added to the raw material of pavement bricks, because it has conventional SiO 2 The special optical properties that it does not have, it has extremely strong ultraviolet absorption and heat radiation absorption characteristics, and its absorption rate of ultraviolet light within a wavelength of 400nm is as high as 70%, so adding it to the aggregate of pavement bricks can achieve anti-ultraviolet The purpose of radiation and thermal aging can reduce the degree of urban heat island effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com