Cable material and preparation method and application thereof

A cable material and raw material technology, applied in the direction of rubber insulators, organic insulators, etc., can solve problems such as uneven quality of high-voltage cables and inconsistent reference standards, and achieve good interface activity, improved tensile strength, and increased interface force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

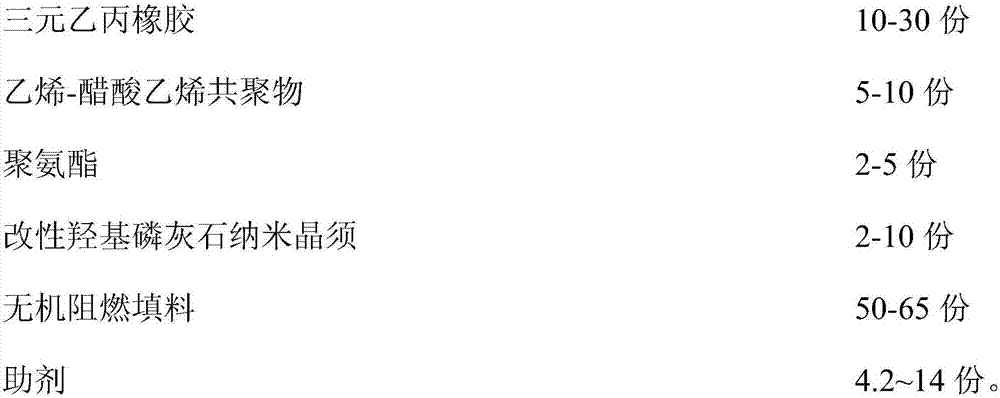

Method used

Image

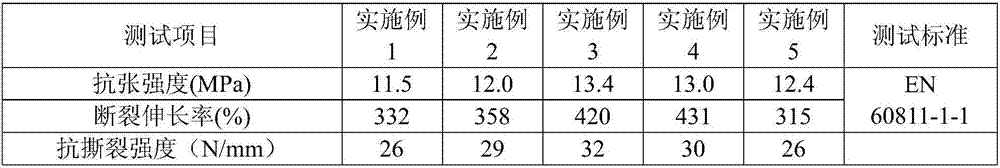

Examples

Embodiment 1

[0064] A preparation method of cable material, said method comprising the following steps:

[0065] (1) 20 parts of EPDM rubber, 8 parts of ethylene-vinyl acetate copolymer, 4 parts of polyester polyurethane, 5 parts of modified hydroxyapatite nano-whiskers, 55 parts of surface-activated aluminum hydroxide, 3 parts of 2,6-di-tert-butyl-4-methylphenol, 3 parts of silicone powder, 1 part of triallyl isocyanurate and 1 part of stearic acid were added to the internal mixer for internal mixing, and After the temperature of the mixer reaches 125°C, the materials are turned over, and the silo and the feeding port are cleaned before the banburying stops. When the temperature reaches 160°C, the banburying is stopped, and the banburying time is 25 minutes, and the dough is obtained;

[0066] (2) Extrude and granulate the dough obtained in step (1) through the first extruder, and the working temperatures of each zone of the first extruder are: feeding zone 115°C, conveying zone 120°C, he...

Embodiment 2

[0071] A preparation method of cable material, said method comprising the following steps:

[0072] (1) 15 parts of EPDM rubber, 10 parts of ethylene-vinyl acetate copolymer, 5 parts of polyether polyurethane, 8 parts of modified hydroxyapatite nano-whiskers, 55 parts of surface-activated magnesium hydroxide, 2 parts of bis(3,5-di-tert-butyl-4-hydroxyphenyl) sulfide, 3 parts of silicone masterbatch, 1 part of trimethylolpropane trimethacrylate and 1 part of stearic acid modified Add the masterbatch into the internal mixer for internal mixing. After the temperature of the internal mixer reaches 128°C, turn over the material. Before the internal mixing stops, clean the silo and the feeding port. When the temperature reaches 165°C, the internal mixing stops. The internal mixing time is 20 Minutes to get dough;

[0073] (2) The dough obtained in step (1) is extruded and granulated through the first extruder, and the working temperatures of each zone of the first extruder are: fee...

Embodiment 3

[0078] A preparation method of cable material, said method comprising the following steps:

[0079] (1) 13 parts of EPDM rubber, 10 parts of ethylene vinyl acetate copolymer, 5 parts of polyester polyurethane, 10 parts of modified hydroxyapatite nano-whiskers, 55 parts of surface-activated aluminum hydroxide, 3 parts Part tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol, 2 parts silicone powder, 1 part trimethylolpropane trimethacrylate, and 1 part stearin Add the acid into the internal mixer for banburying. After the temperature of the internal mixer reaches 130°C, turn over the materials. Before the banburying stops, clean the silo and feeding port. When the temperature reaches 170°C, the banburying stops and the banburying time is 15 minutes. , get dough;

[0080] (2) The dough obtained in step (1) is extruded and granulated through the first extruder, and the working temperatures of each zone of the first extruder are: feeding zone 120°C, conveying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com