Preparation method of waterborne galvanized passivating liquid

A passivation solution, water-based technology, applied in the coating process of metal materials, etc., can solve the problems of affecting the corrosion resistance of the passivation film, micro cracks on the surface of the passivation film, and poor film forming effect, so as to achieve uniform appearance and improve Oxidation performance, effect of improving film formation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

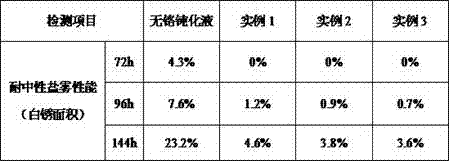

example 1

[0021] First weigh 30g of polyvinyl alcohol, pour it into a beaker containing 800mL of water, stir and mix with a glass rod for 10min, let it stand for 3h, and then move the beaker into a digital-display speed-measuring constant temperature magnetic stirrer, the temperature is 88°C, and the rotation speed is Under the condition of 400r / min, stir and mix at a constant temperature for 60min to obtain a dispersion liquid. Take 100mL of titanium tetrachloride solution with a concentration of 2.0mol / L and 100mL of potassium chloride solution with a concentration of 1.0mol / L in turn, and crush 20g of activated carbon to 120 mesh. , pour it into a three-necked flask, and then move the three-necked flask into a digital-display speed measuring constant temperature magnetic stirrer. Under the conditions of a temperature of 65 °C and a rotation speed of 400 r / min, the constant temperature stirring reaction is performed for 2 hours. When the constant temperature stirring reaction is complet...

example 2

[0023]First, weigh 40 g of polyvinyl alcohol, pour it into a beaker containing 900 mL of water, stir and mix with a glass rod for 13 minutes, let it stand for 4 hours, and then move the beaker into a digital speed measuring constant temperature magnetic stirrer at a temperature of 89 °C and a rotation speed of Under the condition of 500r / min, stir and mix at a constant temperature for 75min to obtain a dispersion liquid, take 110mL of titanium tetrachloride solution with a concentration of 2.3mol / L, 105mL of potassium chloride solution with a concentration of 1.1mol / L, and 25g crushed to 140 mesh activated carbon , pour it into the three-necked flask, and then move the three-necked flask into the digital-display speed measuring constant temperature magnetic stirrer. Under the condition of temperature of 68°C and rotation speed of 500r / min, constant temperature stirring reaction is carried out for 3h. When the constant temperature stirring reaction is over, adjust the stirring sp...

example 3

[0025] First, weigh 50g of polyvinyl alcohol and 60g of sodium silicate, pour them into a beaker containing 1000mL of water, stir and mix with a glass rod for 15min, let stand for 5h, and then move the beaker into a digital speed measuring constant temperature magnetic stirrer, at a temperature of Under the condition of 90 ℃, rotating speed of 600r / min, constant temperature stirring and mixing for 90min, a dispersion liquid was obtained, 120mL of titanium tetrachloride solution with concentration of 2.5mol / L, 110mL of potassium chloride solution with concentration of 1.2mol / L were taken in turn, 30g Grind to 160 mesh of activated carbon, pour it into a three-necked flask, and then move the three-necked flask into a digital-display velocity-measuring constant temperature magnetic stirrer. Under the conditions of a temperature of 70 °C and a rotation speed of 600 r / min, the constant temperature stirring reaction is performed for 4 hours, and the constant temperature stirring react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com