Magnesium alloy anode micro-arc oxidation electrolyte and method for magnesium alloy anode micro-arc oxidation using the electrolyte

A micro-arc oxidation, magnesium alloy technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve problems such as defects of magnesium oxide ceramic layer, increase film-forming stability, change film-forming color, reduce The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

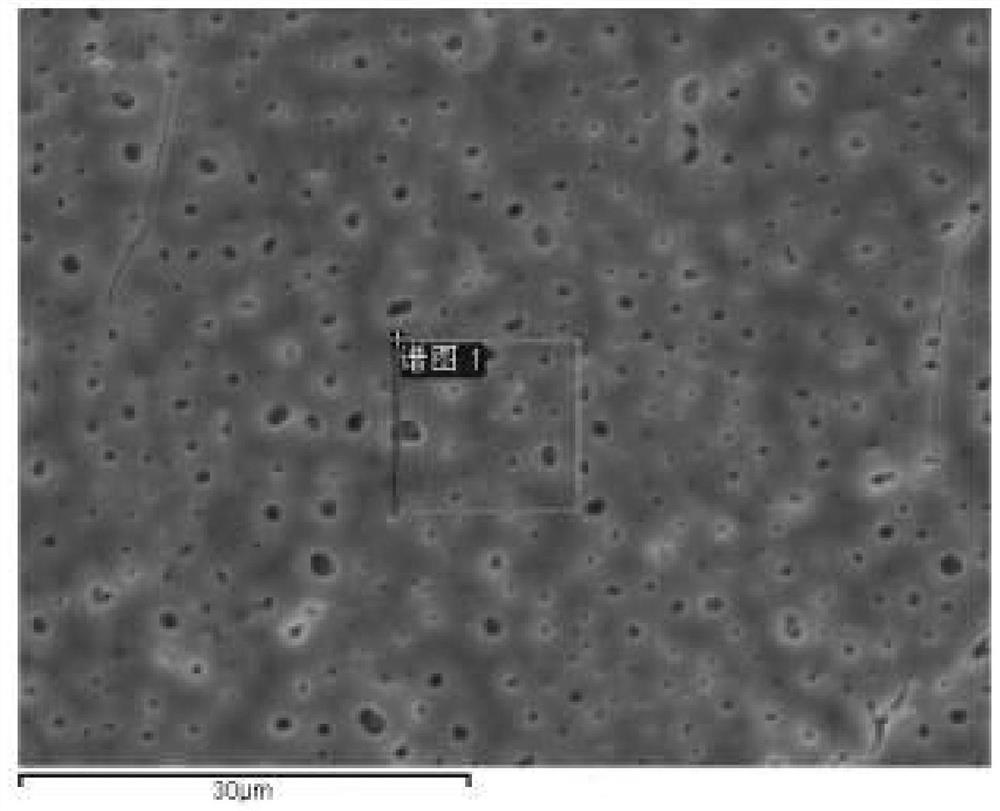

Image

Examples

Embodiment 1

[0024] Magnesium alloy anode micro-arc oxidation electrolyte, the concentration of each component in the electrolyte is:

[0025] 30g / L sodium hydroxide, 30g / L potassium silicate, 30g / L potassium carbonate, 5g / L sodium borate, 5ml / L EDTA, 20ml / L ethylene glycol, 3ml / L glycerol alcohol, 10ml / L triethanolamine, 5ml / L 8-hydroxyquinoline.

[0026] A method for micro-arc oxidation of magnesium alloy anode using magnesium alloy anode micro-arc magnesium oxidation electrolyte, comprising the following steps:

[0027] S1: get the sodium hydroxide of 30g / L, the potassium silicate of 30g / L, the potassium carbonate of 30g / L, the sodium borate of 5g / L, the EDTA of 5ml / L, the ethylene glycol of 20ml / L, 3ml / L glycerol, 10ml / L of triethanolamine, and 5ml / L of 8 hydroxyquinoline were added successively in deionized water, and stirred to dissolve them completely to obtain a magnesium alloy anode micro-arc magnesium oxidation electrolyte;

[0028] S2: prepare a magnesium alloy sample, wash th...

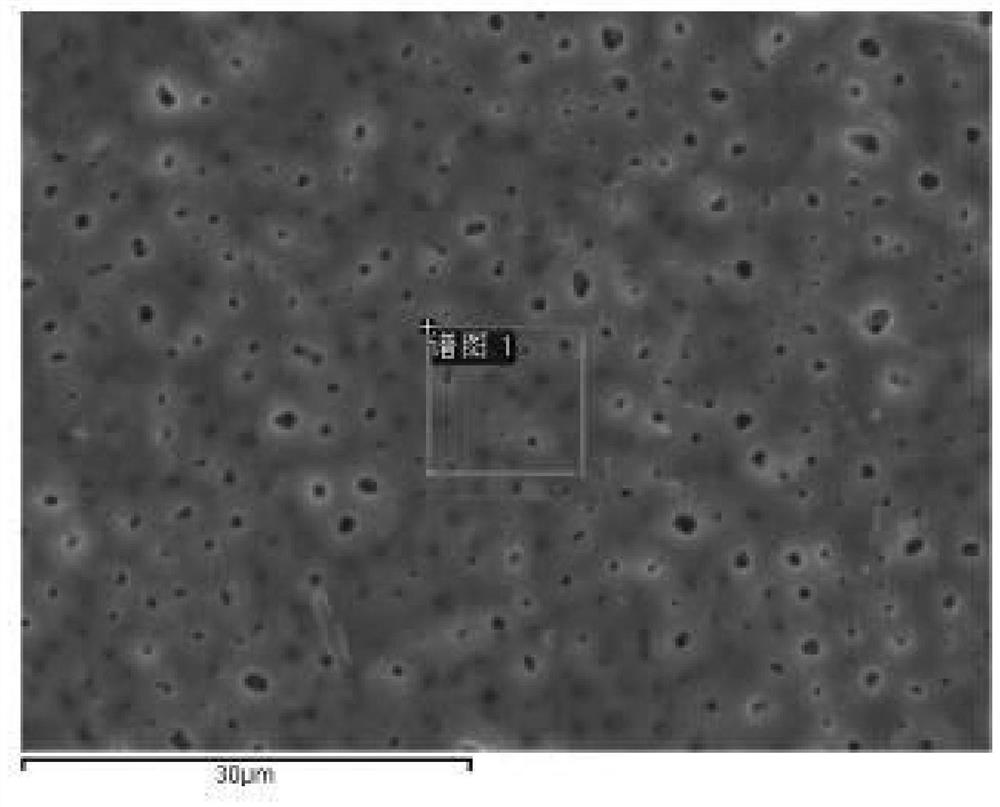

Embodiment 2

[0032] Magnesium alloy anode micro-arc oxidation electrolyte, the concentration of each component in the electrolyte is:

[0033] 10g / L potassium hydroxide, 10g / L sodium silicate, 10g / L sodium carbonate, 18g / L potassium borate, 0.5ml / L EDTA, 5ml / L ethylene glycol, 3ml / L propylene Triol, 3ml / L of triethanolamine, 0.5ml / L of 8-hydroxyquinoline.

[0034] A method for micro-arc oxidation of magnesium alloy anode using magnesium alloy anode micro-arc magnesium oxidation electrolyte, comprising the following steps:

[0035] S1: get the potassium hydroxide of 10g / L, the sodium silicate of 10g / L, the sodium carbonate of 10g / L, the potassium borate of 18g / L, the EDTA of 0.5ml / L, the ethylene glycol of 5ml / L, 3ml / L of glycerol, 3ml / L of triethanolamine, and 0.5ml / L of 8-hydroxyquinoline were successively added to deionized water, and stirred to dissolve completely to obtain a magnesium alloy anode micro-arc magnesium oxidation electrolyte;

[0036] S2: prepare a magnesium alloy sampl...

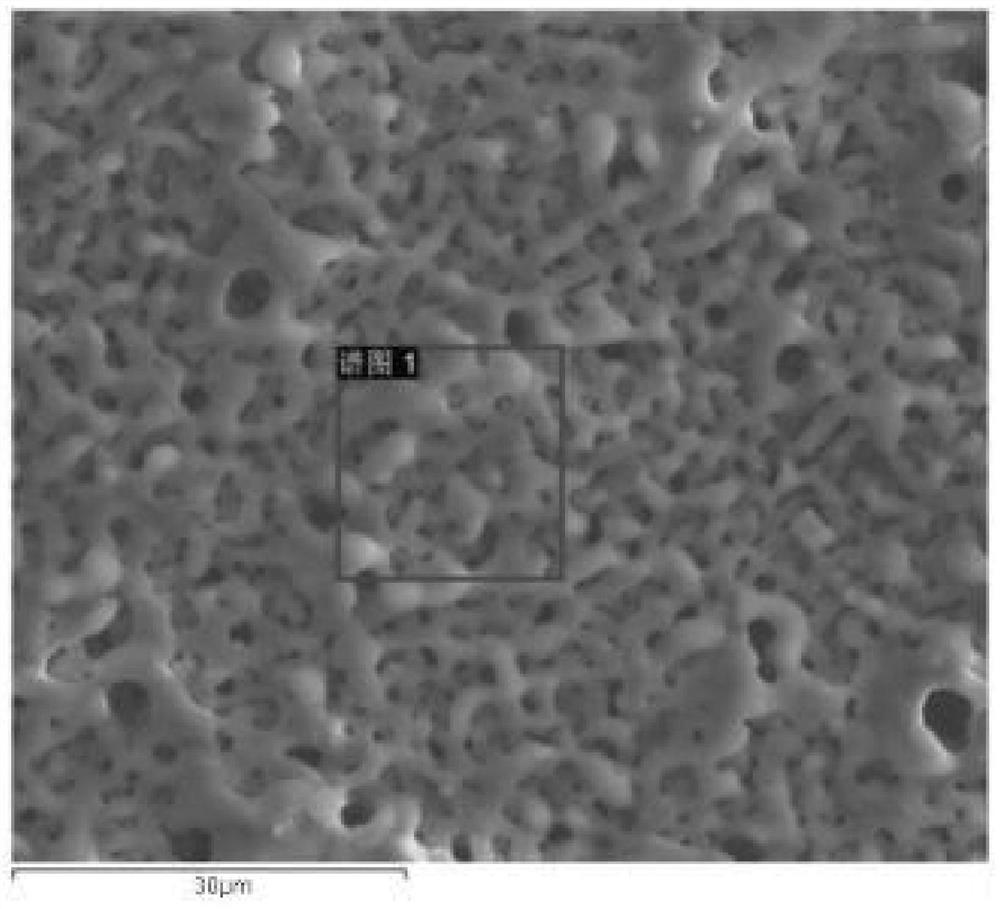

Embodiment 3

[0040] Magnesium alloy anode micro-arc oxidation electrolyte, the concentration of each component in the electrolyte is:

[0041] 60g / L potassium hydroxide and sodium hydroxide mixture, 60g / L sodium silicate and potassium silicate mixture, 20g / L sodium carbonate and potassium carbonate mixture, 30g / L potassium borate, 10ml / L EDTA, 30ml / L ethylene glycol, 15ml / L glycerol, 20ml / L triethanolamine, 10ml / L 8-hydroxyquinoline.

[0042] A method for micro-arc oxidation of magnesium alloy anode using magnesium alloy anode micro-arc magnesium oxidation electrolyte, comprising the following steps:

[0043] S1: get the mixture of potassium hydroxide and sodium hydroxide of 60g / L, the mixture of sodium silicate and potassium silicate of 60g / L, the mixture of sodium carbonate and potassium carbonate of 20g / L, the potassium borate of 30g / L, 10ml / L of EDTA, 30ml / L of ethylene glycol, 15ml / L of glycerol, 20ml / L of triethanolamine, and 10ml / L of 8-hydroxyquinoline were successively added to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com