A kind of graphene polymer fiber and preparation method thereof

A graphene and polymer technology, applied in the field of fiber processing, to achieve the effect of simple and easy method, high degree of irregular shape, and strong conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

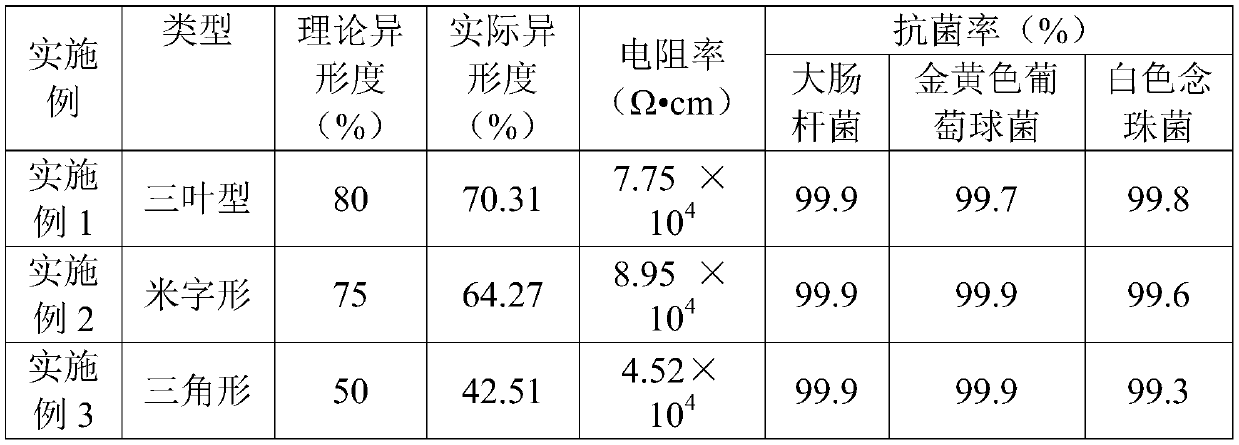

Embodiment 1

[0066] Preparation of high-profile trilobal polyamide 6 / graphene conductive fibers

[0067] After the biomass graphene and polyamide 6 slices with an average particle size of 300nm were dried separately, a coupling agent was added, mixed at a high speed in a kneader, and then a dispersant was added. After further mixing, it was cooled to room temperature and passed through a twin screw extruder. Graphene powder and polyamide 6 slices were blended and granulated, and the temperature of each zone of the screw was 150°C, 240°C, 242°C, 242°C, and 240°C, respectively, to prepare polyamide 6 / graphene with a graphene content of 20 wt%. Master batch, in the master batch, the content of dispersant is 2 wt %, and the content of coupling agent is 1.0 wt %.

[0068] The polyamide 6 / graphene masterbatch and the polyamide 6 chips are weighed and mixed according to a mass ratio of 1:1 as the main component; the water-soluble polyester chips are used as a secondary component. The vacuum drum...

Embodiment 2

[0075] Preparation of M-shaped Polyamide 6 / Graphene Conductive Fibers with High Irregularity

[0076] After the biomass graphene and polyamide 6 slices with an average particle size of 300nm were dried separately, a coupling agent was added, mixed at a high speed in a kneader, and then a dispersant was added. After further mixing, it was cooled to room temperature and passed through a twin screw extruder. Graphene powder and polyamide 6 slices were blended and granulated, and the temperature of each zone of the screw was 150°C, 240°C, 242°C, 242°C, and 240°C, respectively, to prepare polyamide 6 / graphene with a graphene content of 30 wt%. Master batch, in the master batch, the content of dispersant is 3 wt %, and the content of coupling agent is 1.5 wt %.

[0077] The polyamide 6 / graphene master batch and the polyamide 6 chips are weighed and mixed according to a mass ratio of 1:2 as the main component; the water-soluble polyester chips are used as a secondary component. Vacu...

Embodiment 3

[0085] Preparation of equilateral triangular polyamide 6 / graphene conductive fibers with high heterogeneity

[0086] After the biomass graphene and polyamide 6 slices with an average particle size of 300nm were dried separately, a coupling agent was added, mixed at a high speed in a kneader, and then a dispersant was added. After further mixing, it was cooled to room temperature and passed through a twin screw extruder. Graphene powder and polyamide 6 slices were blended and granulated, and the temperature of each zone of the screw was 150°C, 240°C, 242°C, 242°C, and 240°C, respectively, to prepare polyamide 6 / graphene with a graphene content of 40 wt%. Master batch, in the master batch, the content of dispersant is 4 wt %, and the content of coupling agent is 2 wt %.

[0087] The polyamide 6 / graphene masterbatch and the polyamide 6 chips are weighed and mixed according to a mass ratio of 1:3 as the main component; the water-soluble polyester chips are used as a secondary comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com