Avalanche photo-diode based on AlInAsSb body material as multiplication region and preparation method therefor

An avalanche photoelectric and diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as low detection sensitivity, thermal noise limitation of detection sensitivity, and increase system operating costs, achieving high gain-bandwidth product and meeting sensitivity requirements , Reduce the effect of tunneling dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

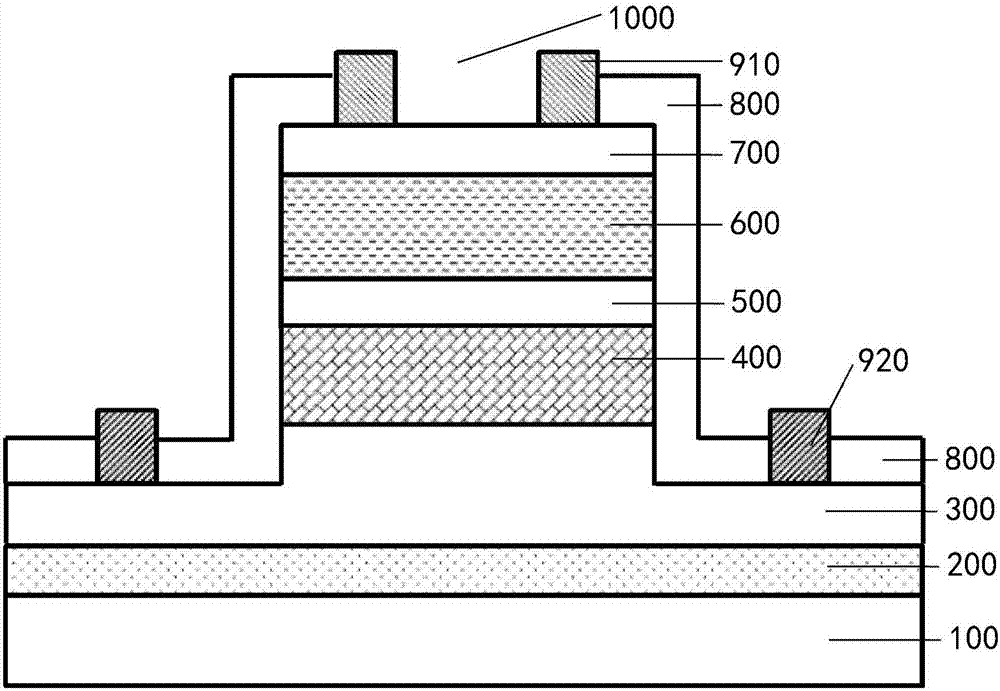

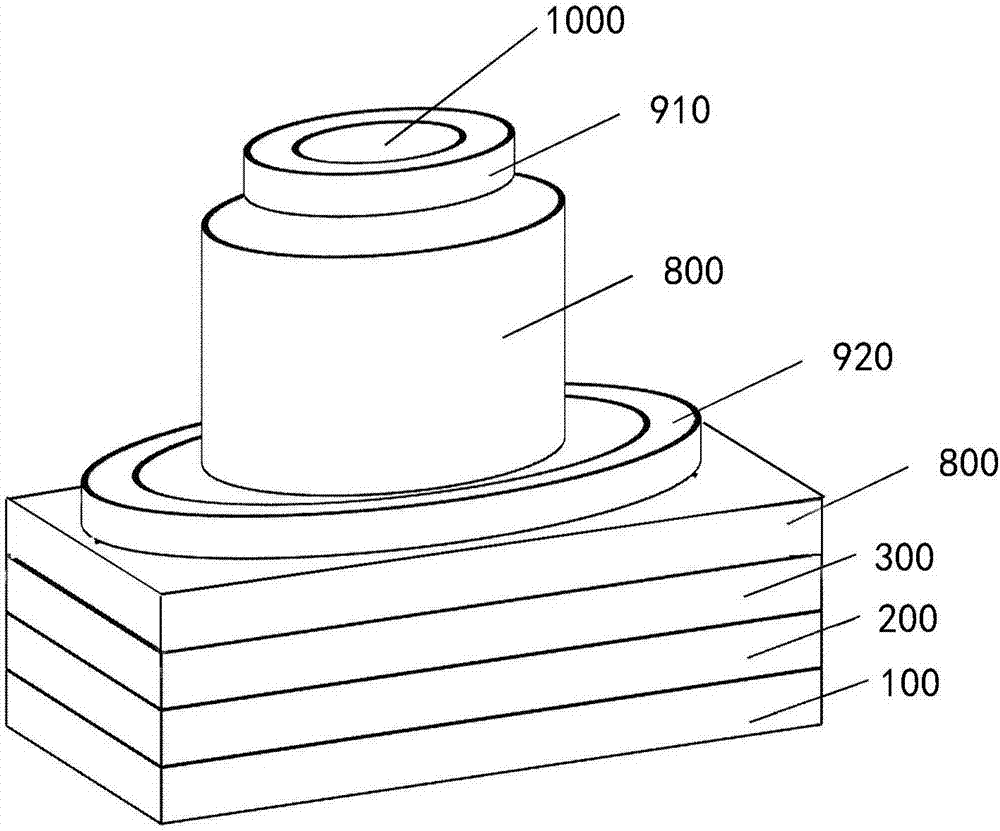

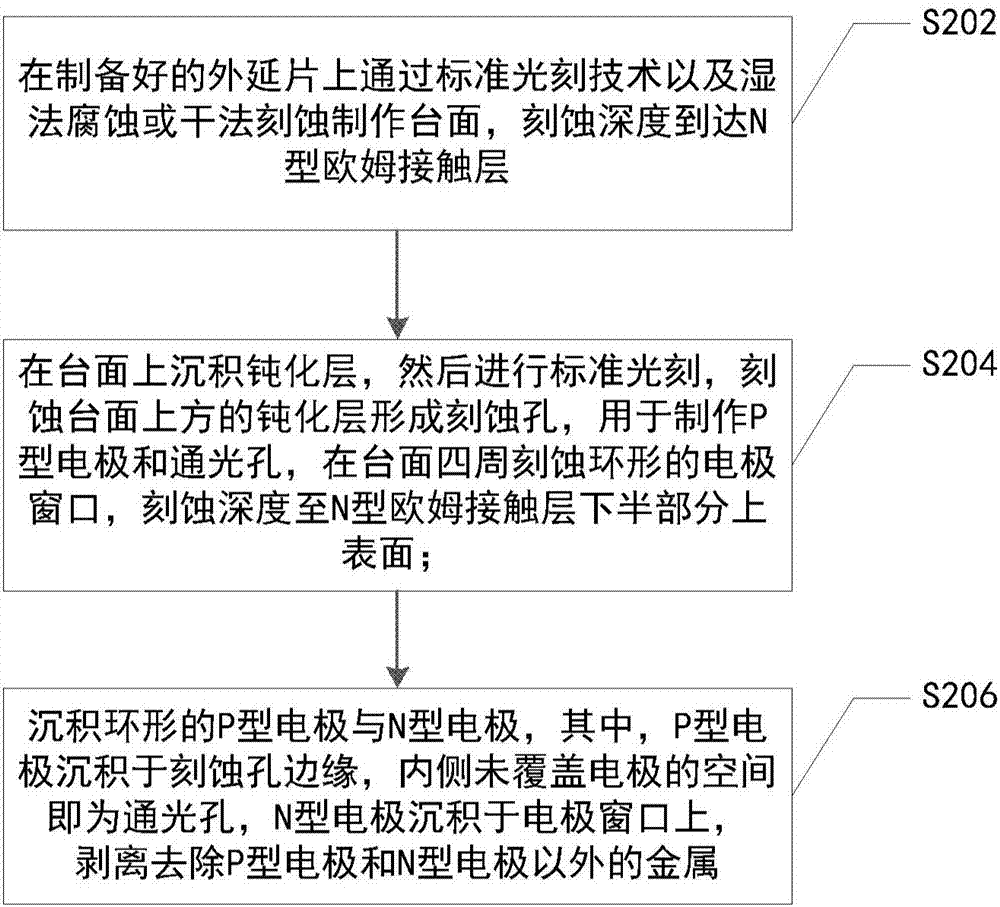

[0039] The invention provides an avalanche photodiode based on AlInAsSb body material as the multiplication region and its preparation method. By using the AlInAsSb body material as the avalanche multiplication layer, it has single-carrier ionization characteristics and does not exist due to the avalanche establishment time. The gain-bandwidth product limitation has the advantages of low noise and high gain-bandwidth product. At the same time, the forbidden band width can be adjusted by using substrates with different lattice constants, which effectively reduces the dark current and meets the needs of photodetectors. At the same time as the high sensitivity requirement, the design of energy band engineering can also be realized, which broadens its scope of application.

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com