Preparation method of composite structured GaN/CdZnTe thin film ultraviolet light detector

A composite structure and detector technology, used in semiconductor/solid-state device manufacturing, semiconductor device, final product manufacturing, etc., can solve problems such as the inability to guarantee the normal use of ultraviolet light detectors, and achieve good stability, light response, and high thermal conductivity. , The effect of high chemical inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] A method for preparing a composite structure GaN / CdZnTe thin film ultraviolet light detector, the method includes the following steps:

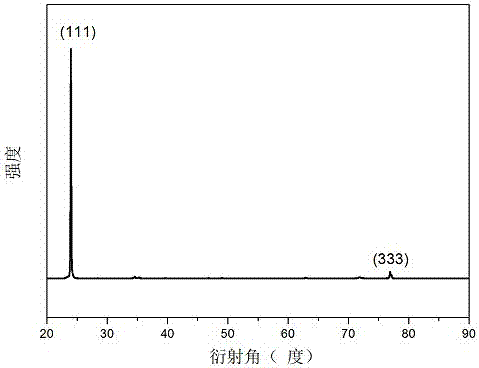

[0021] (1). Preparation of CdZnTe polycrystalline sublimation source: Grind CdZnTe polycrystal into powder as the sublimation source. The CdZnTe polycrystal is a commercial CdZnTe polycrystalline substrate produced by Emei Semiconductor Material Factory; (2). Treatment: Use a monocrystalline silicon wafer plated with gallium nitride (GaN) as the substrate. Wash the substrate with acetone, alcohol, and deionized water for 15 minutes to remove impurities and organics on the surface of the substrate, and then use nitrogen After drying, put it into the sublimation reaction chamber near space;

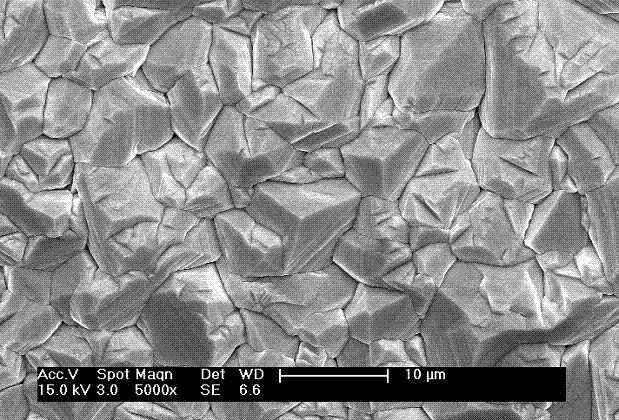

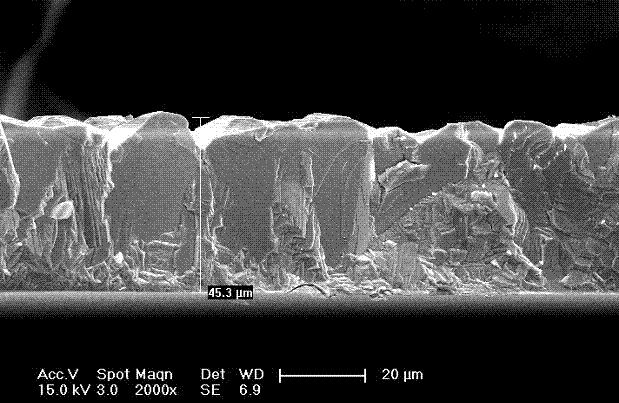

[0022] (3). The growth process of CdZnTe film: turn on the mechanical pump to vacuum, and pump the pressure in the sublimation chamber below 5pa; turn on the halogen lamp to heat the sublimation source and substrate to 600℃ and 550℃ respectively; after 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com