Mineral mycotoxin mold-removing agent and preparation method thereof

A technology of mycotoxins and mold removers, which is applied in the direction of additional food elements, food science, animal feed, etc., can solve problems such as not being suitable for mass production, unusable mold removers, and reduced mold removal effects, so as to enhance the body's immunity force, detoxification, high-efficiency adsorption, and selective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

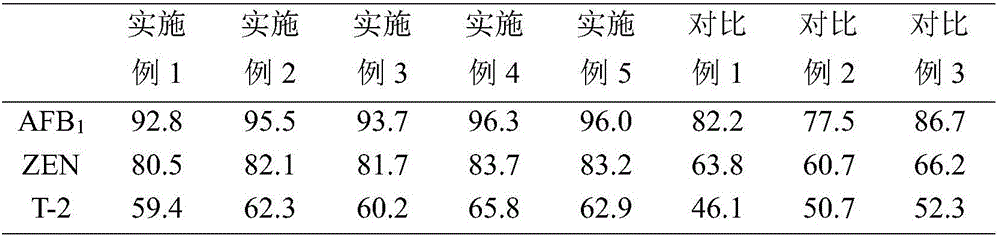

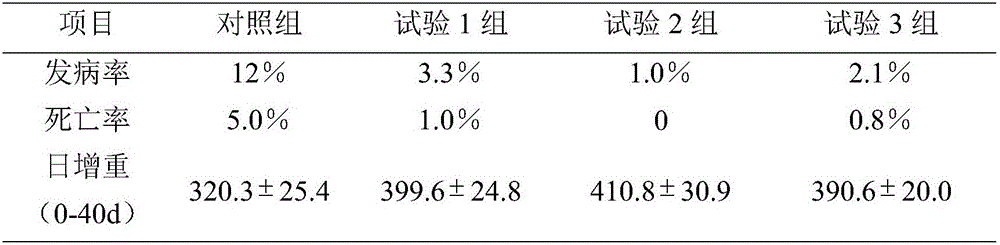

Examples

preparation example Construction

[0018] The preparation method of the mineral mycotoxin remover of the present invention, the steps of the method are: the tourmaline raw material is first circulated on a low-speed mixer for grinding, and then circulated on a high-speed mixer, and the rotating speed of the low-speed mixer is 2000-4000r / min, the speed of the high-speed mixer is 14000-18000r / min, and the tourmaline powder with a particle size of 1.0-3.0μm is obtained; the modified montmorillonite and the modified halloysite are respectively crushed to 100 mesh- 200 meshes; then the pulverized modified montmorillonite, modified halloysite and tourmaline powders were respectively made into 2-4% suspensions, soaked for 16-24 hours, mixed the suspensions, and stirred magnetically for 2 -4h, then centrifuge at 2000-4000r / min for 10-20min, and completely dry at 80-150°C, grind to obtain dried mineral powder; add water, mix the dried mineral powder with vitamin Fully mixed with minerals, dried and sieved to obtain a m...

Embodiment 1

[0030] The weight components of the raw materials of the mineral mycotoxin remover in this embodiment include 60% of modified montmorillonite, 20% of modified halloysite, 10% of ferrite tourmaline, 5% of vitamins and 5% of minerals. The vitamin is a mixture of vitamin C and vitamin E; the mineral is a mixture of zinc methionine and potassium chloride.

[0031] The preparation method of the mineral mycotoxin remover of the present embodiment is:

[0032] (1) Preparation of modified montmorillonite: Weigh 10 g of montmorillonite, disperse it in 200 ml of water, stir with a magnetic stirrer, and heat up to 70-80° C. After stirring for a period of time, add 1 g of cetyltrimethylammonium bromide (CTAB), continue to stir for 4 hours, filter with suction after standing for 8 hours, wash with distilled water, dry, and pass through a 100-mesh sieve to obtain organically modified montmorillonite .

[0033] (2) Preparation of modified halloysite: 100 g of halloysite was weighed and cru...

Embodiment 2

[0037] The weight components of the raw materials of the mineral mycotoxin-removing agent in this embodiment include: 60% of modified montmorillonite, 15% of modified halloysite, 15% of ferrite, 5% of vitamin, and 5% of mineral. The vitamin is a mixture of vitamin C and vitamin E; the mineral is a mixture of zinc methionine and potassium chloride.

[0038] The preparation method of the modified montmorillonite is as follows: disperse the montmorillonite raw material in water, the mass ratio of the montmorillonite raw material to water is 1:15, heat and stir with a magnetic stirrer, raise the temperature to 80° C., and stir for 4 hours; Add cetyltrimethylammonium bromide then, the quality of cetyltrimethylammonium bromide is 1 / 9 of montmorillonite raw material quality, continue to stir 4h, stand still 10h again; Filter, then wash with distilled water, dry, and pass through a 100-mesh sieve to obtain the modified montmorillonite;

[0039] The preparation method of the modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com