Method for synthesizing VIII first-row transition metal and molybdenum/tungsten double-metal carbide catalyst at low temperature

A bimetallic carbide and bimetallic oxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of bimetallic carbide carbon pollution, block active sites, etc., and achieve operational Simple, energy-saving product particles, the effect of less surface carbon pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

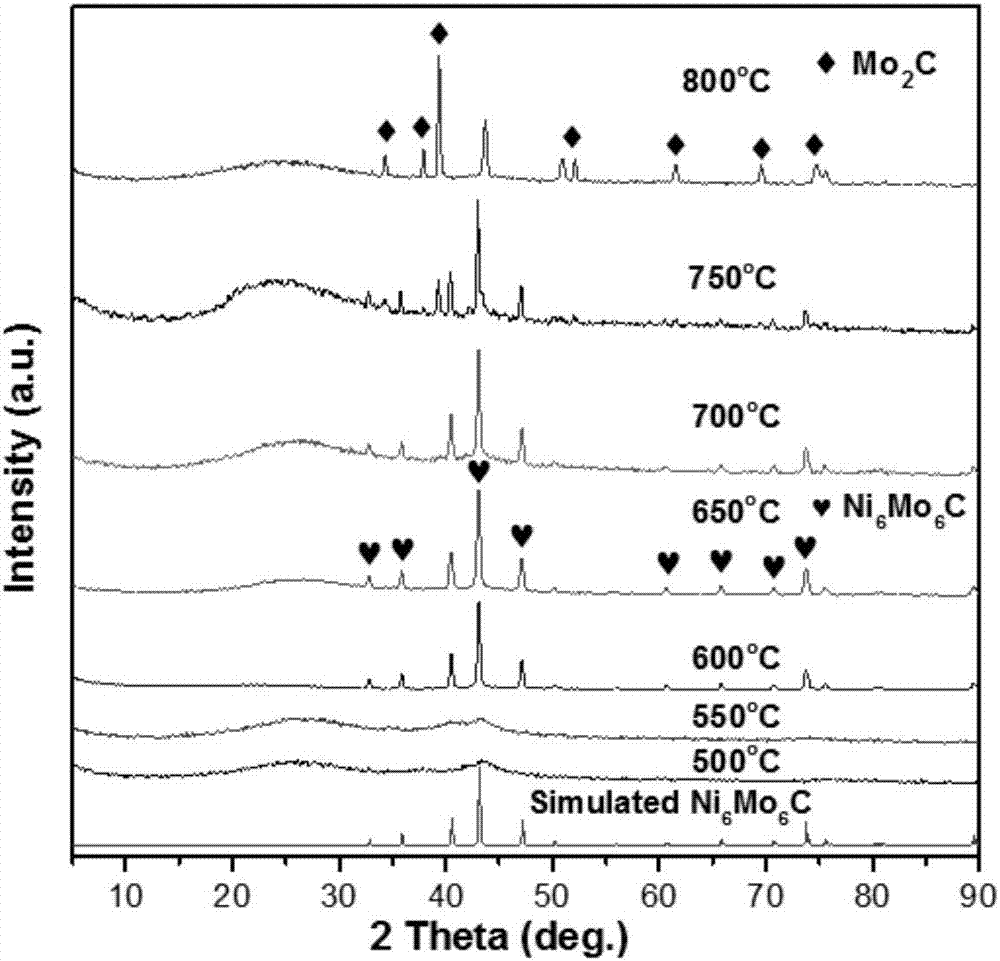

[0026] Embodiment 1: the Na of 0.005mol 2 MoO 4 2H 2 O and 0.005mol Ni(NO 3 ) 2 ·6H 2 O was dissolved in 20 mL deionized water, respectively, and stirred to mix at room temperature. A light green precipitate was obtained, and after stirring for 30 minutes, the mixture was transferred and sealed in a 60 mL polytetrafluoroethylene-lined stainless steel autoclave, and kept in an electric oven at 180 °C for 4 hours. Then the autoclave was taken out from the oven and allowed to cool to room temperature naturally. The yellow-green precipitate was collected by centrifugation, washed well with water and ethanol, and dried overnight at 80 °C. Finally, the product was ground into a fine powder for characterization.

[0027] Activated carbon (AC) was prepared through a chemical activation route from coconut shells. The specific surface area of activated carbon was obtained by the nitrogen adsorption and desorption isotherm measurements at 77 K to be about 1000 m 2 / g, the aver...

Embodiment 2

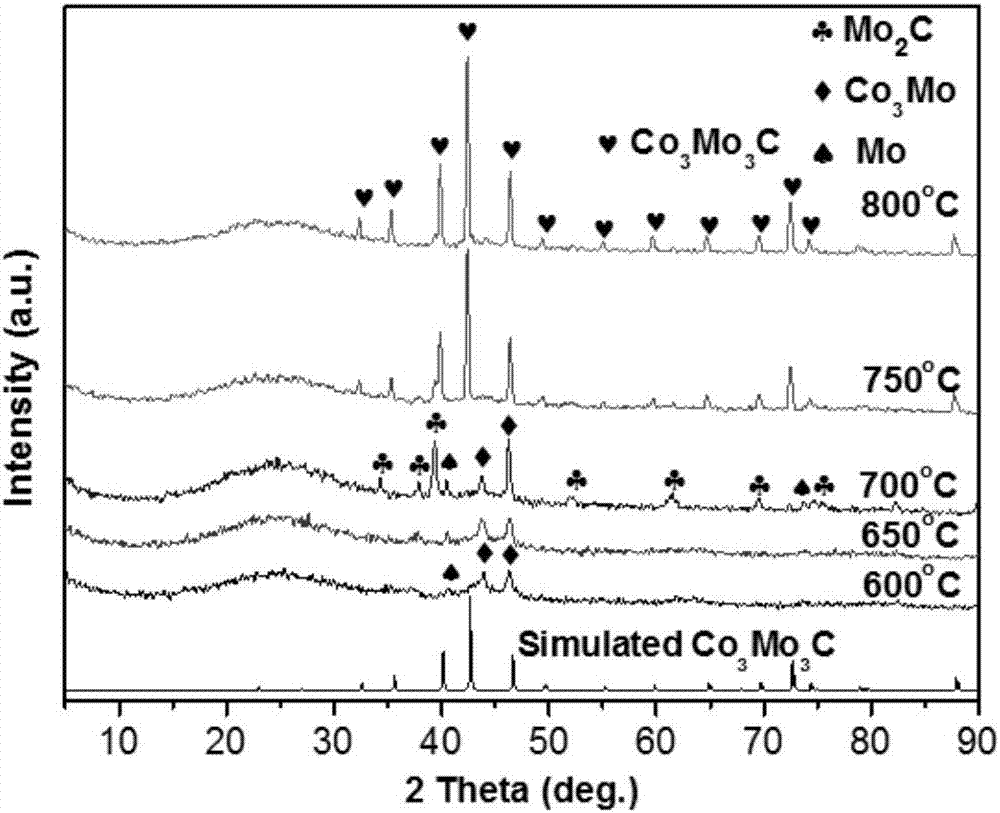

[0028] Embodiment 2: the Na of 0.005mol 2 MoO 4 2H 2 O and 0.005mol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 20 mL deionized water, respectively, and stirred to mix at room temperature. A light green precipitate was obtained, and after stirring for 30 minutes, the mixture was transferred and sealed in a 60 mL polytetrafluoroethylene-lined stainless steel autoclave, and kept in an electric oven at 180 °C for 4 hours. Then the autoclave was taken out from the oven and allowed to cool to room temperature naturally. The yellow-green precipitate was collected by centrifugation, washed well with water and ethanol, and dried overnight at 80 °C. Finally, the product was ground into a fine powder for characterization.

[0029] The as-synthesized bimetallic oxide was mixed with activated carbon so that the molar ratio of total metal to carbon was 1:25, and the mixture was homogeneously ground for 30 min with a mortar and pestle. The resulting mixture (0.5 g) was transferred to a ...

Embodiment 3

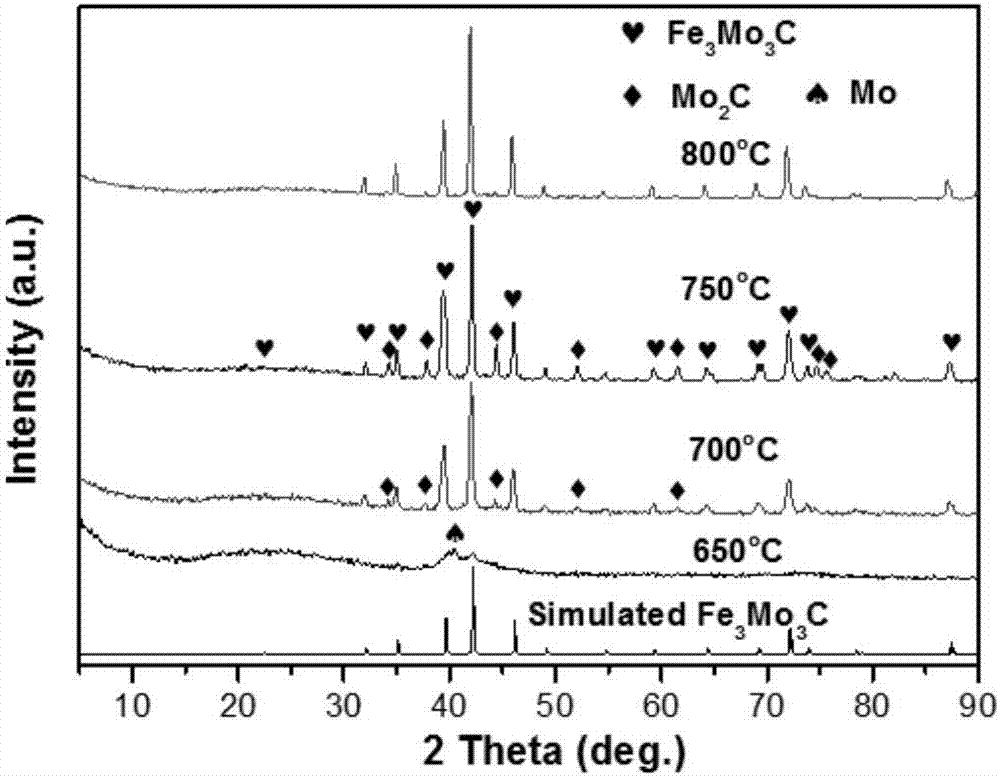

[0030] Embodiment 3: the Na of 0.005mol 2 MoO 4 2H 2 O and 0.005mol FeCl 2 ·6H 2 O was dissolved in 20 mL deionized water, respectively, and stirred to mix at room temperature. A light green precipitate was obtained, and after stirring for 30 minutes, the mixture was transferred and sealed in a 60 mL polytetrafluoroethylene-lined stainless steel autoclave, and kept in an electric oven at 180 °C for 4 hours. Then the autoclave was taken out from the oven and allowed to cool to room temperature naturally. The yellow-green precipitate was collected by centrifugation, washed well with water and ethanol, and dried overnight at 80 °C. Finally, the product was ground into a fine powder for characterization.

[0031] The as-synthesized bimetallic oxide was mixed with activated carbon so that the molar ratio of total metal to carbon was 1:15, and the mixture was uniformly ground for 30 min with a mortar and pestle. The resulting mixture (0.5 g) was transferred to a quartz boat p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com