Starch-based edible packaging film and preparation method thereof

A packaging film, starch-based technology, applied in the field of starch-based edible packaging film and its preparation, can solve the problem of thin edible packaging, etc., and achieve the effects of good stretchability, wide range of sources, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

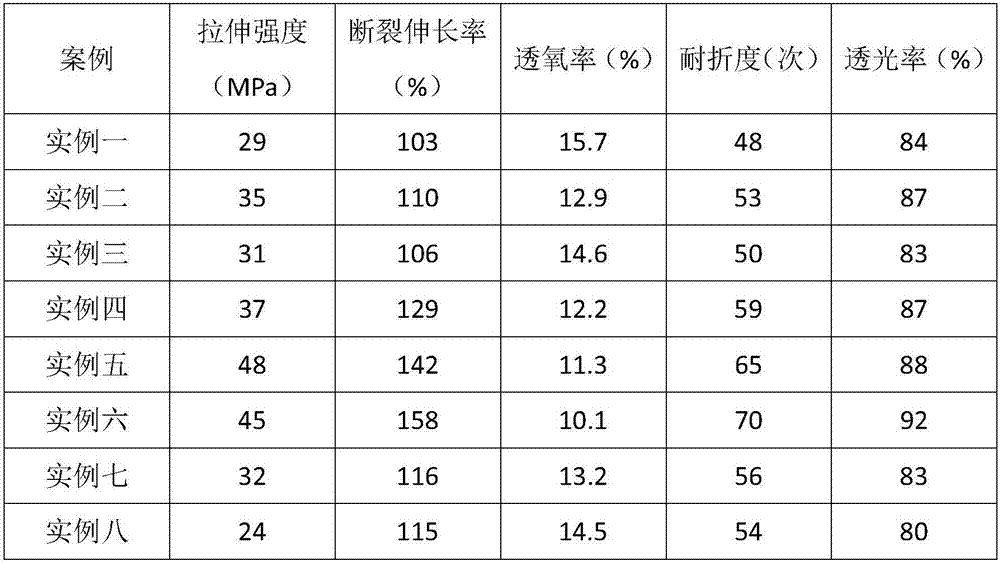

Examples

Embodiment 1

[0028] The raw materials used in this example packaging film are as follows by weight: 67 parts of tapioca starch, 15 parts of sorbitol, 10 parts of glycerin, 3 parts of lauric acid, 3.5 parts of ferulic acid, 1 part of hydroxymethyl cellulose, 8 parts of pullulan 68 parts of chitosan, 65 parts of sodium alginate, 20 parts of gelatin, 1.2 parts of tea polyphenols, and 0.8 parts of butyl anisole.

[0029] The preparation method is as follows:

[0030] 1) taking each raw material component according to the above-mentioned ratio in parts by weight;

[0031] 2) Under the condition of 32°C, uniformly mix glycerin, sorbitol, carboxymethyl cellulose and lauric acid to obtain mixture I;

[0032] 3) Add appropriate amount of water at 32°C to tapioca starch, then add pullulan, gelatin and chitosan, and mix evenly to obtain mixture II;

[0033] 4) Mix mixture I in step (2), mixture II in step (3), sodium alginate, ferulic acid, tea polyphenols and butylanisole, and heat to 72°C to obta...

Embodiment 2

[0037] The raw materials used in this example packaging film are as follows by weight: 77 parts of tapioca starch, 12 parts of sorbitol, 13 parts of glycerin, 1.5 parts of lauric acid, 3 parts of ferulic acid, 1.8 parts of hydroxymethyl cellulose, 11 parts of pullulan 60 parts of chitosan, 55 parts of sodium alginate, 22 parts of gelatin, 1.8 parts of tea polyphenols, and 1.2 parts of butyl anisole.

[0038] The preparation method is as follows:

[0039] 1) taking each raw material component according to the above-mentioned ratio in parts by weight;

[0040] 2) Under the condition of 32°C, uniformly mix glycerin, sorbitol, carboxymethyl cellulose and lauric acid to obtain mixture I;

[0041] 3) Add appropriate amount of water at 32°C to tapioca starch, then add pullulan, gelatin and chitosan, and mix evenly to obtain mixture II;

[0042] 4) Mix mixture I in step (2), mixture II in step (3), sodium alginate, ferulic acid, tea polyphenols and butylanisole, and heat to 72°C to ...

Embodiment 3

[0046] The raw materials used in this example packaging film are as follows by weight: 85 parts of tapioca starch, 13 parts of sorbitol, 12.5 parts of glycerin, 1.8 parts of lauric acid, 4.5 parts of ferulic acid, 3 parts of hydroxymethyl cellulose, 10.5 parts of pullulan 67 parts of chitosan, 58 parts of sodium alginate, 30 parts of gelatin, 3 parts of tea polyphenols, 1.5 parts of butyl anisole.

[0047] The preparation method is as follows:

[0048] 1) taking each raw material component according to the above-mentioned ratio in parts by weight;

[0049] 2) Under the condition of 32°C, uniformly mix glycerin, sorbitol, carboxymethyl cellulose and lauric acid to obtain mixture I;

[0050] 3) Add appropriate amount of water at 32°C to tapioca starch, then add pullulan, gelatin and chitosan, and mix evenly to obtain mixture II;

[0051] 4) Mix mixture I in step (2), mixture II in step (3), sodium alginate, ferulic acid, tea polyphenols and butylanisole, and heat to 72°C to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com