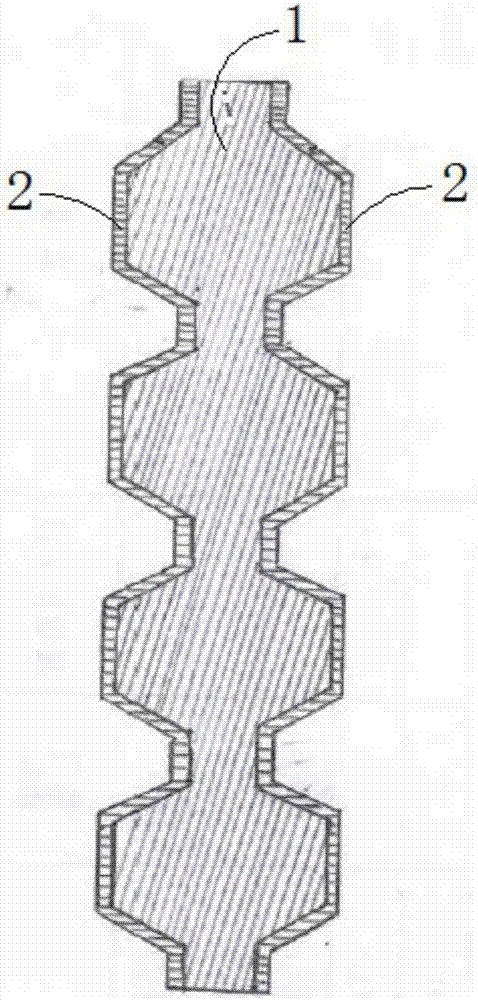

Fuel cell bipolar plate and preparation method of titanium thin films on surfaces thereof

A fuel cell and bipolar plate technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as accelerated corrosion, increased conductivity, and increased contact resistance of bipolar plates, achieving good corrosion resistance and excellent conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

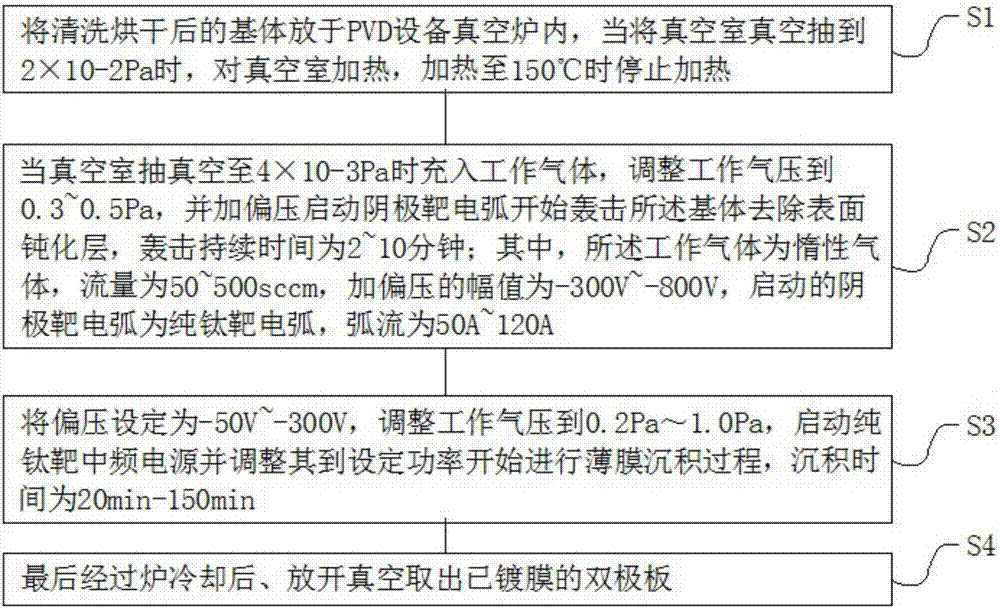

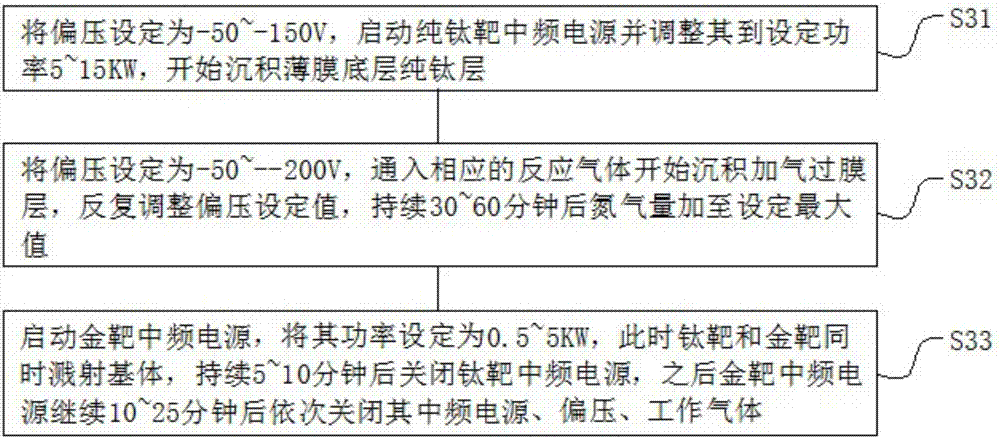

[0061] After pre-cleaning and drying the stainless steel bipolar plate, fix it with a fixture and put it into the vacuum furnace of PVD equipment, and install a cylindrical pure titanium target and a cylindrical pure gold target on the cathode target; to 2×10 -2 At Pa, turn on the heating system to heat the vacuum chamber to 150°C and turn off the heating system; when evacuated to 4×10 -3 Pa, fill the argon gas pressure to 0.30pa, the argon gas flow rate is 50sccm, turn on the pulse bias voltage of -300×40KHZ×75%, start the cathode cylindrical pure titanium target arc, the arc current is 120A, and use the arc light evaporated by the target arc The discharge plasma and the glow discharge plasma of a small amount of inert gas bombard (sputter) the substrate to remove the surface passivation layer. After 10 minutes, the bias voltage is reduced to -100×40KHZ×75%, and the arc power supply of the cylindrical pure titanium target is turned off. Turn on the intermediate frequency pow...

Embodiment 2

[0063] After pre-cleaning and drying the stainless steel bipolar plate, fix it with a fixture and put it into the vacuum furnace of PVD equipment, and install a cylindrical pure titanium target and a cylindrical pure gold target on the cathode target; to 2×10 -2 At Pa, turn on the heating system to heat the vacuum chamber to 150°C and turn off the heating system; when evacuated to 4×10 -3 Pa, fill the argon gas pressure to 0.40pa, the argon gas flow rate is 300sccm, turn on the pulse bias voltage of -800×40KHZ×50%, start the cathode cylindrical pure titanium arc target, the arc current is 50A, and use the arc light evaporated by the target arc The discharge plasma and the glow discharge plasma of a small amount of inert gas bombard (sputter) the substrate to remove the surface passivation layer, and after 2 minutes, reduce the bias voltage to -150×40KHZ×75%, turn off the power of the column arc target and turn on the magnetron Cylindrical titanium target intermediate frequenc...

Embodiment 3

[0065] After pre-cleaning and drying the stainless steel bipolar plate, fix it with a fixture and put it into the vacuum furnace of PVD equipment, and install a cylindrical pure titanium target and a cylindrical pure gold target on the cathode target; to 2×10 -2 At Pa, turn on the heating system to heat the vacuum chamber to 150°C and turn off the heating system; when evacuated to 4×10 -3 Pa, fill the argon gas pressure to 0.50pa, argon gas flow rate is 500sccm, turn on the pulse bias voltage of -500×40KHZ×75%, start the cathode cylindrical pure titanium target arc, the arc current is 80A, and use the arc light evaporated by the target arc The discharge plasma and the glow discharge plasma of a small amount of inert gas bombard (sputter) the substrate to remove the surface passivation layer. After 5 minutes, the bias voltage is reduced to -50×40KHZ×75%, and the arc power supply of the cylindrical pure titanium target is turned off. Turn on the intermediate frequency power sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com