Iron oxide/nano kaolin-containing composite hemostatic and preparation method thereof

A nano-kaolin and iron oxide technology, which is applied in the direction of drug combination, surgical adhesives, medical preparations containing active ingredients, etc., can solve the problems of high content of natural mineral impurities, complex processing procedures, and low safety in use, and achieve High biocompatibility, high safety performance, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a kind of preparation of nano-kaolin, prepared according to the following method:

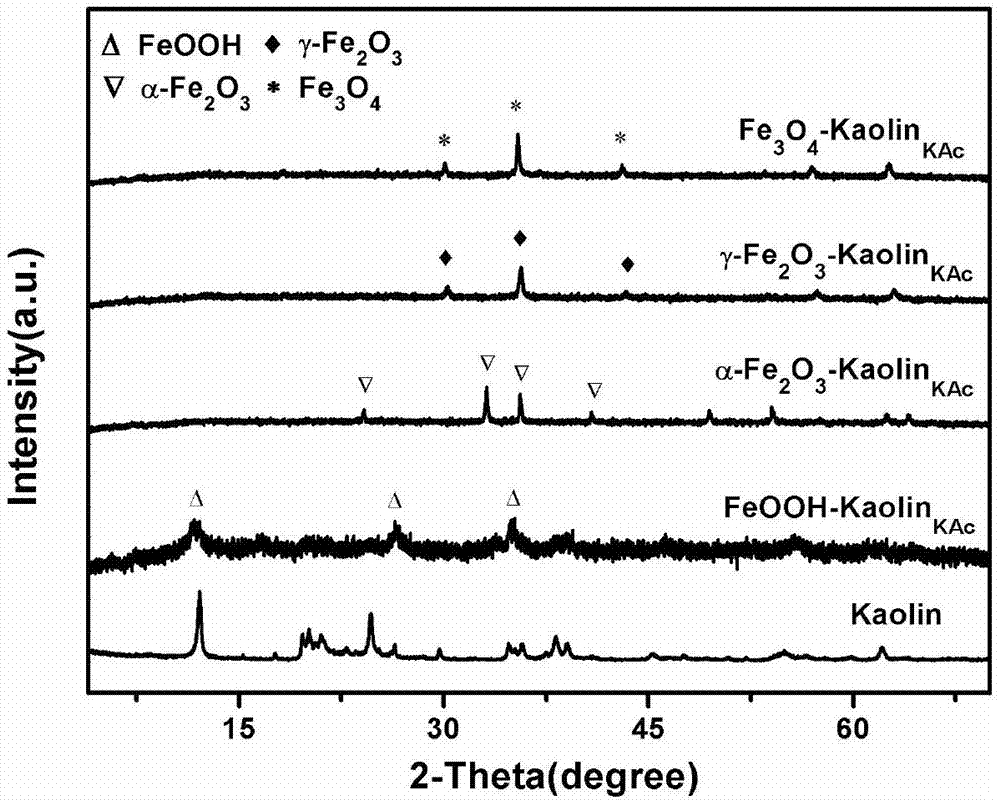

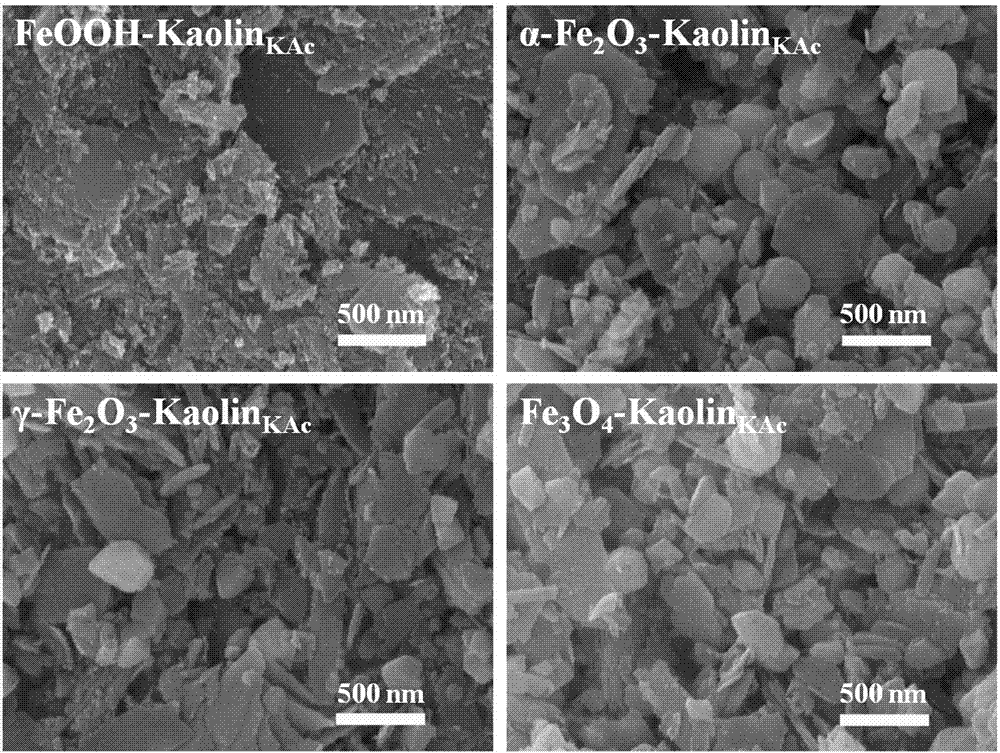

[0043] Weigh 4g of kaolin, add 10g of potassium acetate, grind for about 30min until it becomes a paste, add 10% deionized water, transfer it to a beaker, and let it stand at room temperature for three days. Wash with ethanol, filter, and dry at 60°C for 24h. Potassium acetate was intercalated with kaolin, added to deionized water, ultrasonically treated for 30 minutes, washed, filtered and dried. Tagged as Kaolin KAc .

Embodiment 2

[0045] This example provides the preparation of a polymeric hydroxy iron ion, which is prepared according to the following method: Weigh 2.4 g of sodium hydroxide, add 150 mL of water, and prepare a 0.4 mol / L sodium hydroxide solution. Weigh 10.8g FeCl 3 .6H 2O, add 100mL deionized water to prepare 0.4mol / L FeCl 3 solution. Slowly add 150 mL of 0.4 mol / L NaOH solution dropwise into 100 mL of 0.4 mol / L FeCl under vigorous stirring in a water bath at 70°C 3 solution, after the dropwise addition, take it out and slowly lower the temperature to obtain a stable reddish-brown transparent iron polymer solution for future use. Labeled Polymerized Hydroxyferric Ion Solution.

Embodiment 3

[0047] This example provides an iron oxyhydroxide / nano-kaolin composite hemostatic agent, which is prepared according to the following method:

[0048] Weigh 5g of kaolin after potassium acetate intercalation treatment, and add it into 250mL of 0.4M polyhydroxyferric ion solution. The pH of the reaction system was adjusted to 5 with 5M NaOH solution. Heated to 60°C in a water bath and stirred magnetically for 72h. Wash, separate, and dry at 60°C for 24h. Keep airtight in a desiccant with color-changing silica gel placed at the bottom for later use. Tagged FeOOH-Kaolin KAc .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com