Preparation method of visible sulfanilamide molecular engram detection membrane

A technology of molecular imprinting and sulfonamide, applied in chemical instruments and methods, other chemical processes, color/spectral characteristics measurement, etc., can solve the problems of cumbersome detection process and high cost, and achieve good optical characteristics, easy recycling, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Prepare nanocrystalline cellulose (NCC), adjust the pH of NCC to 2.4 and the concentration to 3.8wt% by centrifugation and dialysis.

[0038] (2) Synthesize the imprinted precursor polymer of sulfonamide resin, and dissolve it with a mixed solvent of ethanol and water (15 / 85v / v%) to form a 40wt% mixed solution for use.

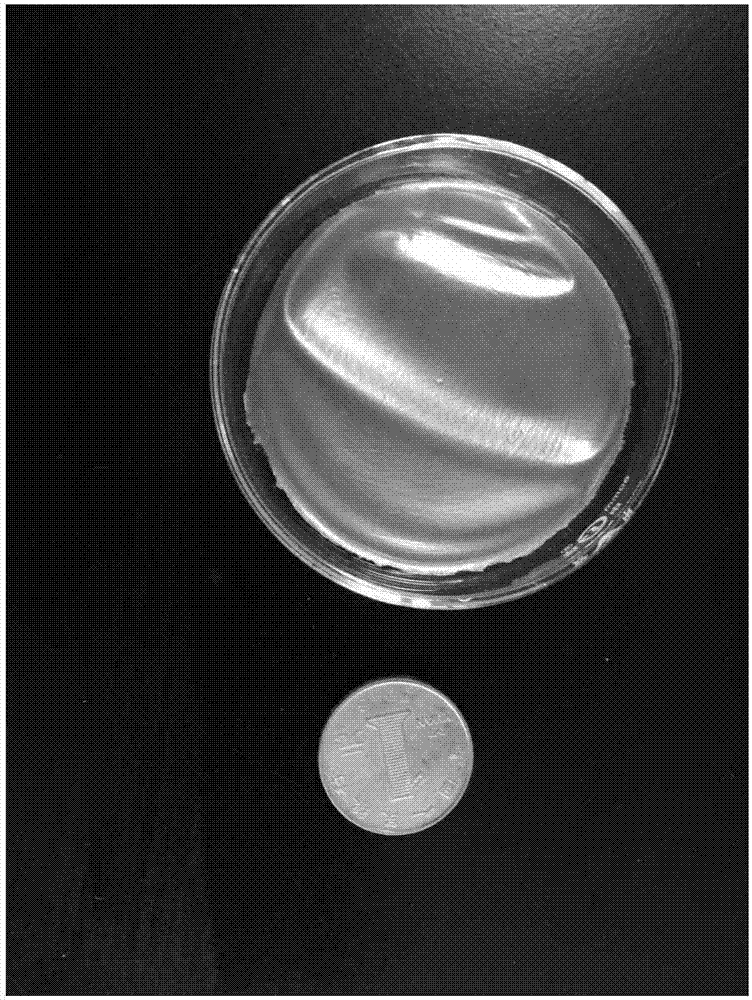

[0039] (3) After ultrasonically degassing the NCC suspension in step (1) for 20 min, draw 10 mL of NCC into a 25 mL round-bottomed flask, and add 300 μL of the resin imprinted precursor polymer solution in step (2) dropwise. The reaction was stirred at room temperature for 4h. Place it in a constant temperature water bath at 22°C to dry to form a film, that is, the sulfonamide molecularly imprinted composite film.

[0040](4) Place the membrane material in 16% sodium hydroxide eluting solution, and elute in a constant temperature water bath at 70° C. for 7-12 hours. After taking it out, first wash and soak it with a large amount of water, and then...

Embodiment 2

[0047] (1) Prepare nanocrystalline cellulose (NCC), adjust the pH of NCC to 2.4 and the concentration to 3.8wt% by centrifugation and dialysis.

[0048] (2) Synthesize the imprinted precursor polymer of sulfonamide resin, and dissolve it with a mixed solvent of ethanol and water (15 / 85v / v%) to form a 40wt% mixed solution for use.

[0049] (3) After ultrasonically degassing the NCC suspension in step (1) for 20 min, draw 10 mL of NCC into a 25 mL round-bottomed flask, and add 400 μL of the resin imprinted precursor polymer solution in step (2) dropwise. The reaction was stirred at room temperature for 4h. Place it in a constant temperature water bath at 22°C to dry to form a film, that is, the sulfonamide molecularly imprinted composite film.

[0050] (4) Place the membrane of (3) in a 16% sodium hydroxide elution solution, and elute in a constant temperature water bath at 70° C. for 7-12 hours. After taking it out, first wash and soak it with a large amount of water, and the...

Embodiment 3

[0054] (1) Prepare nanocrystalline cellulose (NCC), adjust the pH of NCC to 2.4 and the concentration to 3.8wt% by centrifugation and dialysis.

[0055] (2) Synthesize the imprinted precursor polymer of sulfonamide resin, and dissolve it with a mixed solvent of ethanol and water (15 / 85v / v%) to form a 40wt% mixed solution for use.

[0056] (3) After ultrasonically degassing the NCC suspension in step (1) for 20 min, pipette 10 mL into a 25 mL round-bottomed flask, and add 500 μL of the resin imprinted precursor polymer solution in step (2) dropwise. The reaction was stirred for 4h. Place it in a constant temperature water bath at 22°C to dry to form a film, that is, the sulfonamide molecularly imprinted composite film.

[0057] (4) Place the membrane material in 16% sodium hydroxide eluting solution, and elute in a constant temperature water bath at 70° C. for 7-12 hours. After taking it out, first wash and soak it with a large amount of water, and then use a mixed solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com