Water quality improver for shrimp farming and preparation method thereof

A water quality improver and solution technology, applied in chemical instruments and methods, applications, fish farming, etc., can solve the problems of poor water quality, increase in chemical oxygen consumption and biological oxygen consumption, affecting the growth of aquatic animals, etc. The effect of improving water quality, improving water quality, inhibiting the growth of harmful bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

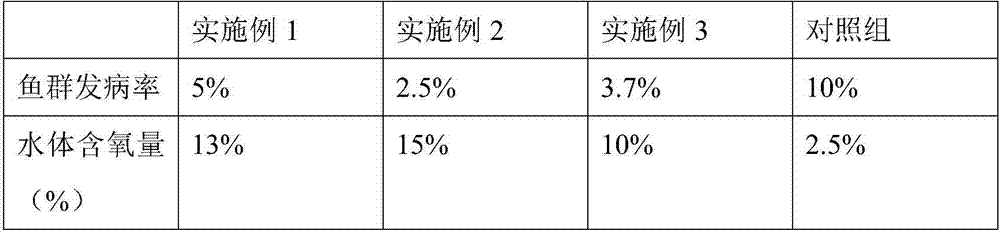

Embodiment 1

[0021] A water quality improver for shrimp culture, the water quality improver for shrimp culture includes the following raw materials in parts by weight: 30 parts of oyster shell powder, 10 parts of amino acids, 3 parts of trace element solution, 10 parts of vitamin solution, 6 parts of traditional Chinese medicine solution 2 parts, 2 parts of fermented organic matter, 2 parts of sodium humate, 1 part of polyferric sulfate, 2 parts of calcium sulfate, and 3 parts of molasses.

[0022] The preparation method of the oyster shell powder comprises the following steps: soaking the oyster shell in hydrochloric acid with a concentration of 8-% for 20 hours, cleaning it and drying it at a place with a temperature of 50°C, and drying the dried oyster shell through After being pulverized by a pulverizer, pass through a 200-mesh sieve to obtain oyster shell powder.

[0023] The amino acid is one or more of lysine, tryptophan, phenylalanine, methionine, isoleucine and glycine.

[0024] ...

Embodiment 2

[0032] A water quality improver for shrimp farming, the water quality improver for shrimp includes the following raw materials in parts by weight: 305 parts of oyster shell powder, 12 parts of amino acids, 4 parts of trace element solution, 11 parts of vitamin solution, 8 parts of traditional Chinese medicine solution 6 parts, 6 parts of fermented organic matter, 4 parts of sodium humate, 3 parts of polyferric sulfate, 3 parts of calcium sulfate, and 5 parts of molasses.

[0033] The preparation method of the oyster shell powder comprises the following steps: soaking the oyster shell in 10% hydrochloric acid for 22 hours, cleaning it and drying it at a temperature of 60°C, and crushing the dried oyster shell After being pulverized by a machine, pass through a 230-mesh sieve to obtain oyster shell powder.

[0034] The amino acid is one or more of lysine, tryptophan, phenylalanine, methionine, isoleucine and glycine.

[0035] The vitamin solution is composed of 30% vitamin C, 1...

Embodiment 3

[0043] A water quality improver for shrimp culture, the water quality improver for shrimp comprises the following raw materials in parts by weight: 40 parts of oyster shell powder, 15 parts of amino acids, 6 parts of trace element solution, 12 parts of vitamin solution, 10 parts of traditional Chinese medicine solution 8 parts of fermented organic matter, 6 parts of sodium humate, 5 parts of polyferric sulfate, 5 parts of calcium sulfate, and 7 parts of molasses.

[0044] The preparation method of the oyster shell powder comprises the following steps: soaking the oyster shell in 12% hydrochloric acid for 24 hours, cleaning it and drying it at a temperature of 70°C, and crushing the dried oyster shell After being pulverized by a machine, pass through a 260-mesh sieve to obtain oyster shell powder.

[0045] The amino acid is one or more of lysine, tryptophan, phenylalanine, methionine, isoleucine and glycine.

[0046] The vitamin solution is composed of 40% vitamin C, 15% vitam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com