A kind of degradable thioaliphatic aromatic polyester and its preparation method

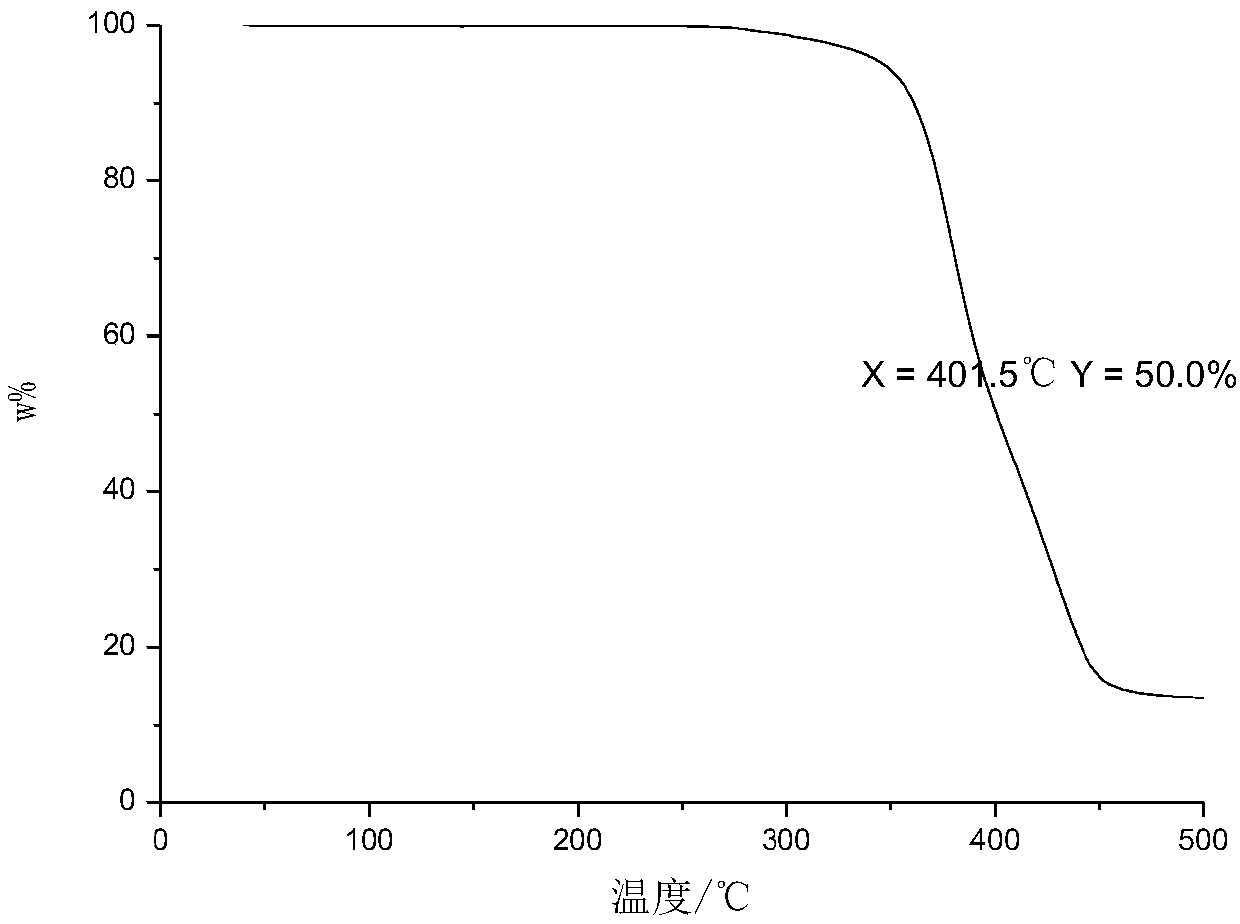

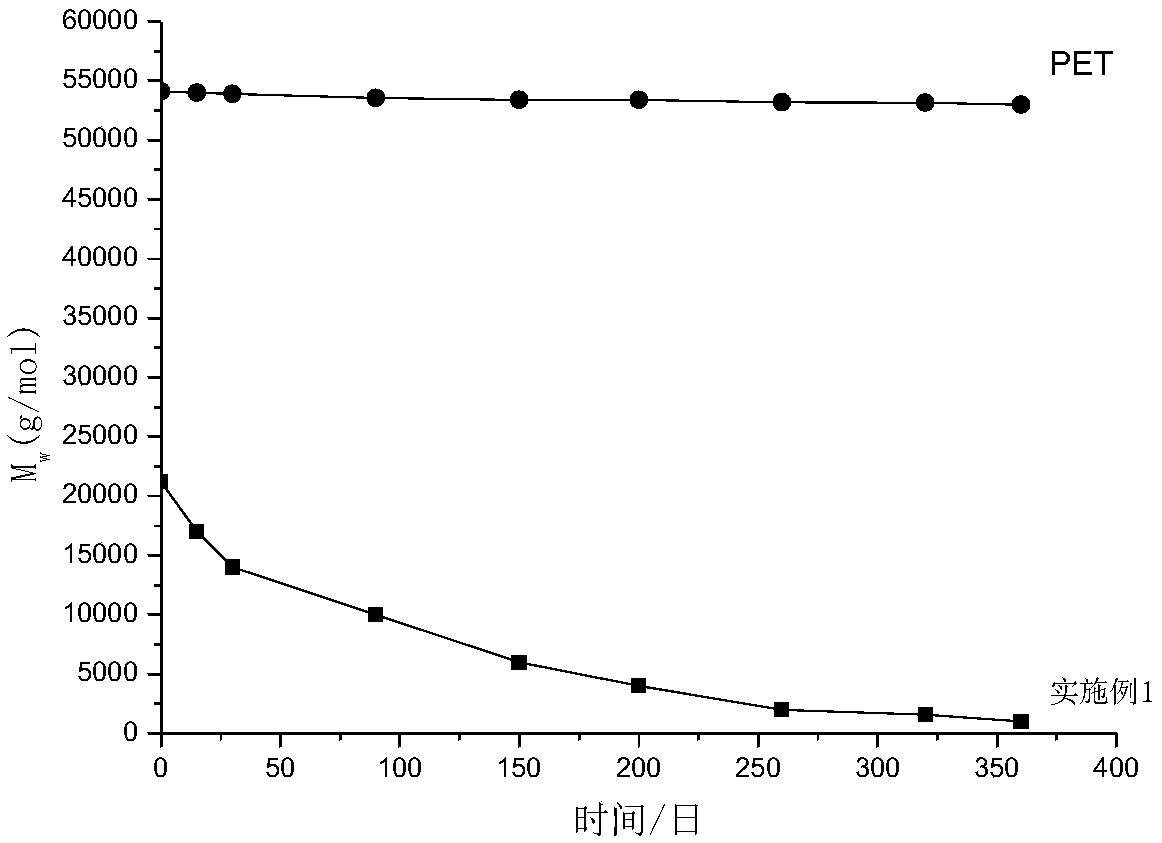

An aliphatic aromatic and aromatic binary technology, applied in the field of organic synthesis, can solve the problems of poor degradation performance, poor thermal performance, low decomposition temperature, etc., achieve good thermal stability, solve white pollution, and excellent degradation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the aliphatic aromatic polyester of the embodiment of the present invention, described method comprises:

[0029] Put thiodipropionic acid, aromatic dihydric alcohol and catalyst at 150°C-190°C under the protection of nitrogen for esterification reaction to obtain intermediate products;

[0030] The feeding of nitrogen gas is stopped, and the intermediate product is placed at 190° C. to 230° C. and 50 Pa to 1000 Pa for polycondensation reaction to obtain polyester.

[0031] The polyester obtained above is a crude product, and a purification step for the crude polyester may also be provided.

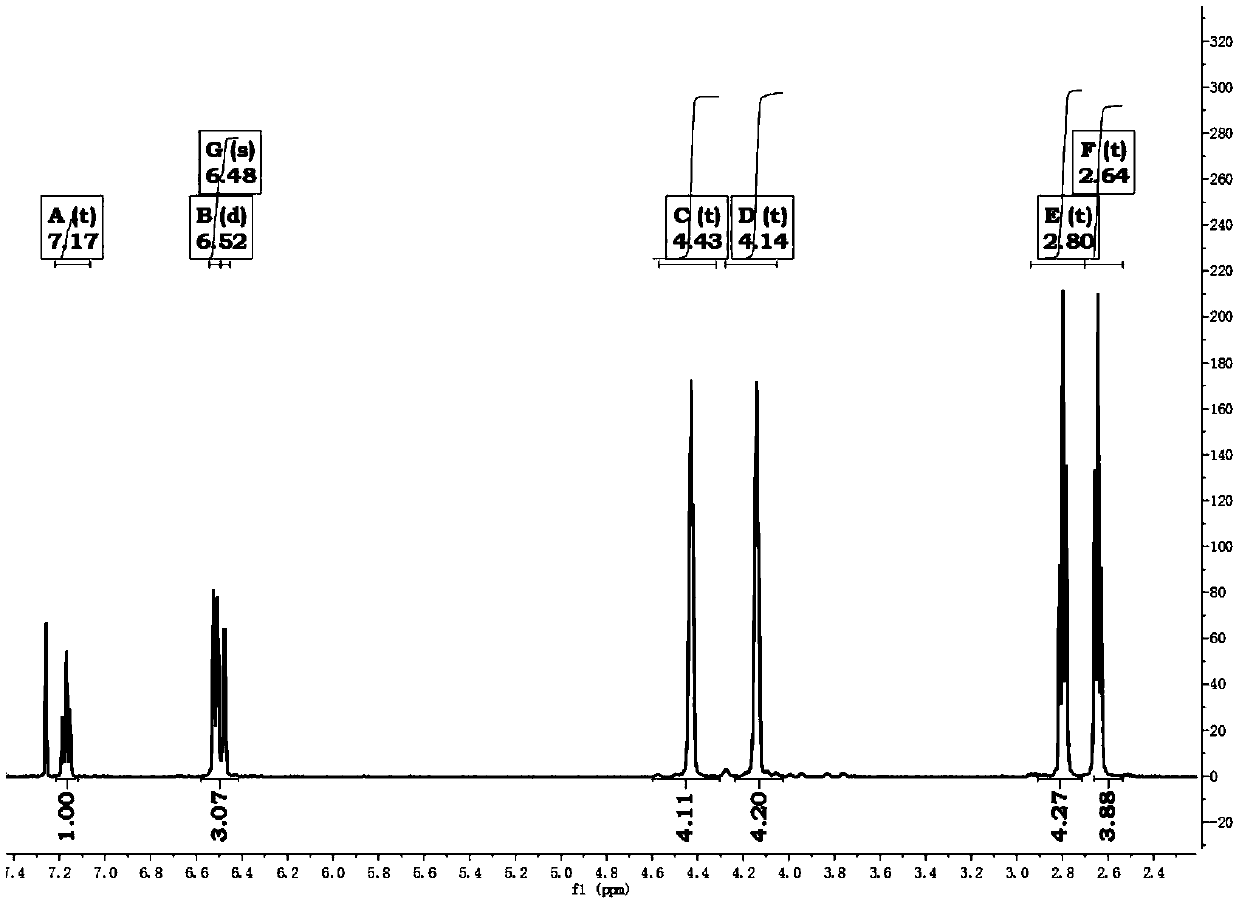

Embodiment 1

[0034] The preparation method of poly(thiodipropionic acid-resorcinol bis(2-hydroxyethyl) ether) ester is as follows:

[0035] Add 2.673g of thiodipropionic acid, 2.973g of resorcinol bis(2-hydroxyethyl)ether and 0.020g of antimony trioxide into a 50ml one-necked flask, and carry out esterification reaction at 101KPa, 170°C and nitrogen atmosphere 2.5 hours. After the above-mentioned esterification reaction, the nitrogen flow was stopped, and at 190°C, the vacuum was evacuated to 600 Pa, and the polycondensation reaction was carried out for 1.5 hours, and then the temperature was raised to 215°C, and the vacuum was evacuated to 70 Pa, and the polycondensation reaction was carried out for 2 hours to obtain crude polyester. Afterwards, polyester purification: add 19mL chloroform to the crude polyester, and after most of the polyester is dissolved, take the clear liquid with a syringe, drop it into methanol, and centrifuge the solution after precipitation is formed, filter, wash ...

Embodiment 2

[0041] The preparation method of poly(thiodipropionic acid-resorcinol bis(2-hydroxyethyl) ether) ester is as follows:

[0042] Add 2.673g of thiodipropionic acid, 2.973g of resorcinol bis(2-hydroxyethyl)ether and 0.020g of n-butyl titanate into a 50ml one-necked flask, and conduct esterification reaction at 160°C for 2.5 hours under nitrogen atmosphere . After the esterification reaction, the nitrogen flow was stopped, and under the condition of 200°C, the vacuum was evacuated to 600 Pa, and the polycondensation reaction was carried out for 2 hours, then the temperature was raised to 220°C, and the vacuum was evacuated to 50 Pa, and the polycondensation reaction was carried out for 2 hours to obtain crude polyester. Purify the crude polyester product: add 18mL chloroform to the crude polyester product, and after most of the polyester dissolves, take the clear liquid with a syringe, drop it into ethanol to form a precipitate, then centrifuge, filter, wash with alcohol, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com