Method for cladding vanadium phosphate on lithium ion battery anode material lithium cobalt nickel manganate

A technology for nickel-cobalt lithium manganate and lithium-ion batteries, which is applied in the field of high-capacity vanadium phosphate-coated lithium-ion battery cathode material nickel-cobalt manganate lithium, and can solve the problems of poor stability, low electronic conductivity, and poor ion transmission performance. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention comprises the following steps:

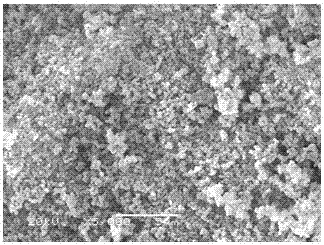

[0024] (1) Weigh 0.3183g (1.75mmol) vanadium pentoxide, 0.4026g (3.5mmol) ammonium dihydrogen phosphate, 0.4413g (3.5mmol) oxalic acid dihydrate, and mix vanadium pentoxide, ammonium dihydrogen phosphate, dihydrate Dissolve oxalic acid in 70ml of deionized water, adjust PH=5 with ammonia water, stir at 80°C for 2 hours, then place in a reaction kettle, and conduct a hydrothermal reaction at 200°C for 24 hours; after the reaction is completed, filter, wash, and dry to obtain vanadium phosphate (VPO 4 );

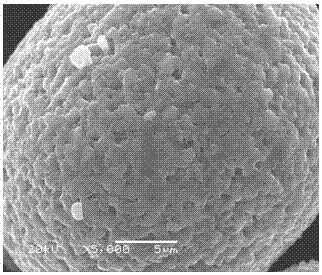

[0025] (2) The nickel-cobalt lithium manganate ternary cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 Add 4.75g and 0.25g of vanadium phosphate obtained in step (1) into a high-speed mixer, and stir for 2 hours at 1000rpm until a uniform product is obtained;

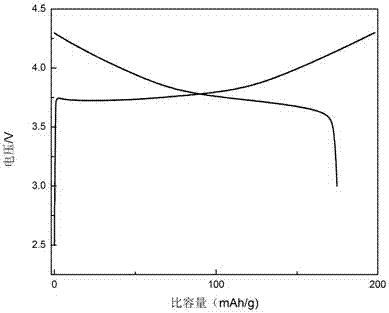

[0026] (3) The mixture treated in step (2) was sintered in an argon furnace at 300°C for 2 hours to obtain nickel-cobalt-lithium-manganese-cobalt-manganate...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] (1) Weigh 0.0819g (0.7mmol) ammonium metavanadate, 0.0805g (0.7mmol) diammonium hydrogen phosphate, 0.265g dihydrate oxalic acid (1.05mmol), and mix ammonium metavanadate, diammonium hydrogen phosphate, dihydrate Dissolve oxalic acid in 70ml of deionized water, adjust PH=2 with ammonia water, stir at 90°C for 4 hours to obtain a homogeneous solution, heat the obtained solution in a reaction kettle at 240°C for 48 hours; filter, wash, and dry to obtain phosphoric acid after the reaction is completed Vanadium (VPO 4 );

[0037] (2) The nickel-cobalt lithium manganate ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Add 4.5g and 0.5g of vanadium phosphate obtained in step (1) into a high-speed mixer, and stir at 500rpm for 4h until a uniform product is obtained;

[0038] (3) The mixture treated in step (2) was sintered in an argon furnace at 200°C for 5 hours, and after cooling, nickel cobalt lithium manganes...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] (1) Weigh 3.1829g (0.0175mol) vanadium pentoxide, 4.0261g (0.035mol) ammonium dihydrogen phosphate, 4.4122g (0.035mol) oxalic acid dihydrate, and mix vanadium pentoxide, ammonium dihydrogen phosphate, dihydrate Dissolve oxalic acid in 70ml of deionized water, adjust PH=7 with ammonia water, stir at 80°C for 2 hours to obtain a homogeneous solution, put the obtained solution in a reaction kettle and heat it at 160°C for 48 hours; after the reaction is completed, filter, wash, and dry to obtain Vanadium Phosphate (VPO 4 );

[0043] (2) The nickel-cobalt lithium manganate ternary cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 Add 9.9g and 0.1g of vanadium phosphate obtained in step (1) into a high-speed mixer, and stir for 2 hours at 1000rpm until a uniform product is obtained;

[0044] (3) The mixture treated in step (2) was sintered in an argon furnace at 300° C. for 2 hours, and cooled to obtain nickel cobalt li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com