Heat-resistant protecting agent, room-temperature-preserved swine fever live vaccine and preparation method and application of room-temperature-preserved swine fever live vaccine

A heat-resistant protective agent and live vaccine technology, which is applied in biochemical equipment and methods, vaccines, veterinary vaccines, etc., to achieve the effect of reasonable matching, low loss and maintaining activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

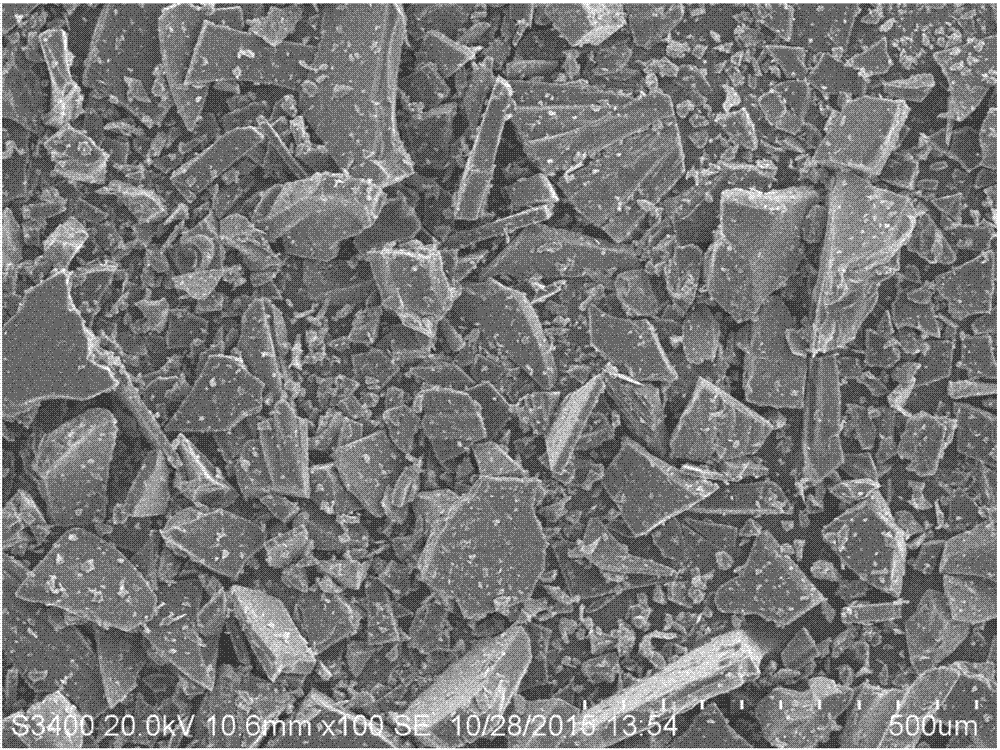

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 heat-resistant protective agent 1 and swine fever live vaccine 1

[0035] Unless otherwise specified, the percentages in this embodiment are percentages by weight.

[0036] Heat-resistant protectant 1 recipe:

[0037]

[0038] The specific preparation steps of heat-resistant protective agent 1 are as follows: dissolve raffinose, maltose, sucrose, lactose, glucose, and polysorbate 80 in water, and sterilize by high-pressure steam sterilization (110° C. for 20 min); Diol 8000, tyrosine, and silk fibroin are dissolved in water, and sterilized by 0.22 μm filtration; the autoclaved part and the filtered sterilized part are mixed in equal volumes, and water for injection is supplemented to obtain the heat-resistant protective agent 1 .

[0039] Preparation of swine fever live vaccine 1: heat-resistant protective agent 1 and swine fever virus liquid (C strain, virus content 50 × 10 4 RID / mL) was mixed at a volume ratio of 3:1, distributed ...

Embodiment 2

[0041] The preparation of embodiment 2 heat-resistant protective agent 2 and swine fever live vaccine 2

[0042] Unless otherwise specified, the percentages in this embodiment are percentages by weight.

[0043] Heat Resistant Protectant 2 Recipe:

[0044]

[0045] The specific preparation steps of the heat-resistant protective agent 2 are as follows: dissolve raffinose, maltose, sucrose, lactose, glucose, polysorbate 80 in water, and sterilize by high-pressure steam sterilization; polyethylene glycol 8000, phenolic acid Amino acid and silk fibroin are dissolved in water, and are sterilized by filtration; equal volumes of the autoclaved part and the filtered sterilized part are mixed, and water for injection is supplemented to obtain the heat-resistant protective agent 2.

[0046] Preparation of swine fever live vaccine 2: heat-resistant protective agent 2 and swine fever virus liquid (C strain, virus content 50 × 10 4 RID / mL) was mixed at a volume ratio of 1:1, divided int...

Embodiment 3

[0048] The preparation of embodiment 3 heat-resistant protective agent 3 and swine fever live vaccine 3

[0049] Unless otherwise specified, the percentages in this embodiment are percentages by weight.

[0050] Heat Resistant Protectant 3 Recipe:

[0051]

[0052] The specific preparation steps of the heat-resistant protective agent 3 are as follows: dissolve raffinose, maltose, sucrose, lactose, glucose, polysorbate 80 in water, and sterilize by high-pressure steam sterilization; polyethylene glycol 8000, phenolic acid Amino acid and silk fibroin are dissolved in water, and are sterilized by filtration; equal volumes of the autoclaved part and the filtered sterilized part are mixed, and water for injection is supplemented to obtain the heat-resistant protective agent 3.

[0053] Preparation of swine fever live vaccine 3: heat-resistant protective agent 3 and swine fever virus liquid (C strain, virus content 50 × 10 4 RID / mL) was mixed at a volume ratio of 3:1, subpackag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com