Preparation method for lignin reduced gold nanoparticle modified carbon nitride for efficiently treating organic pollution

A nano-gold particle, organic pollution technology, applied in the field of materials, can solve the problems of catalytic efficiency limitation, low carrier transport efficiency hindrance, poor electrical conductivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

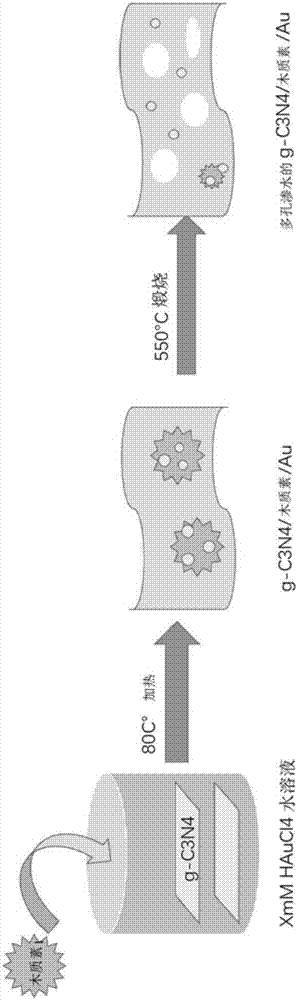

[0033] The invention provides a method for preparing carbon nitride modified by lignin-reduced nano-gold particles for efficient treatment of organic pollution, comprising the following steps:

[0034] (1) Carbon nitride semiconductors are prepared by high-temperature calcination in a muffle furnace, and carbon nitride powders with better catalytic performance are prepared by controlling the type of precursor, heating rate, calcination temperature, calcination time, and annealing method;

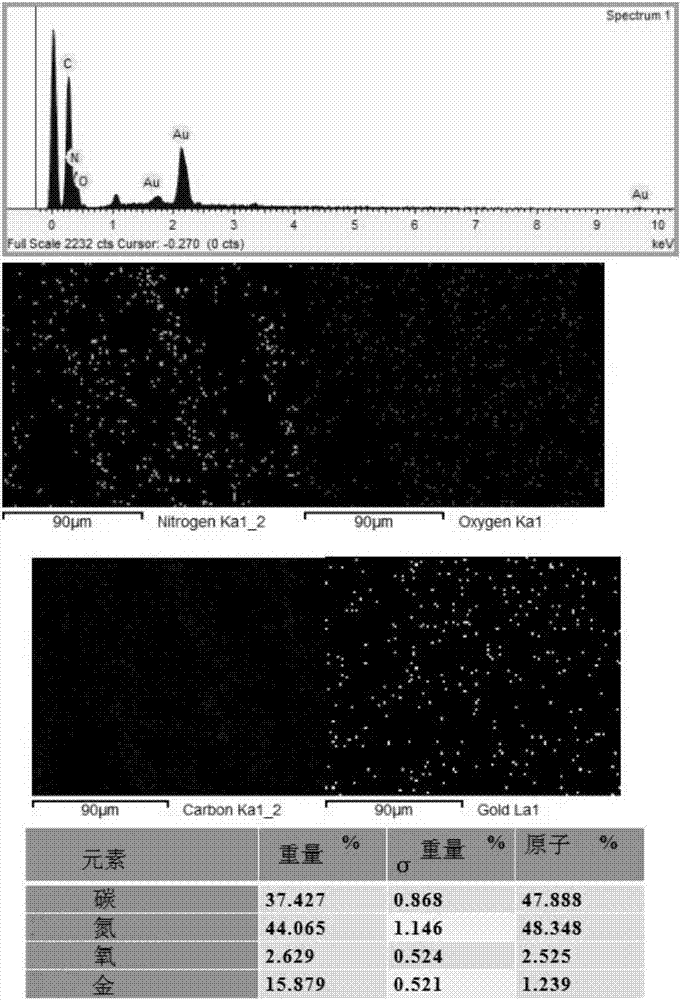

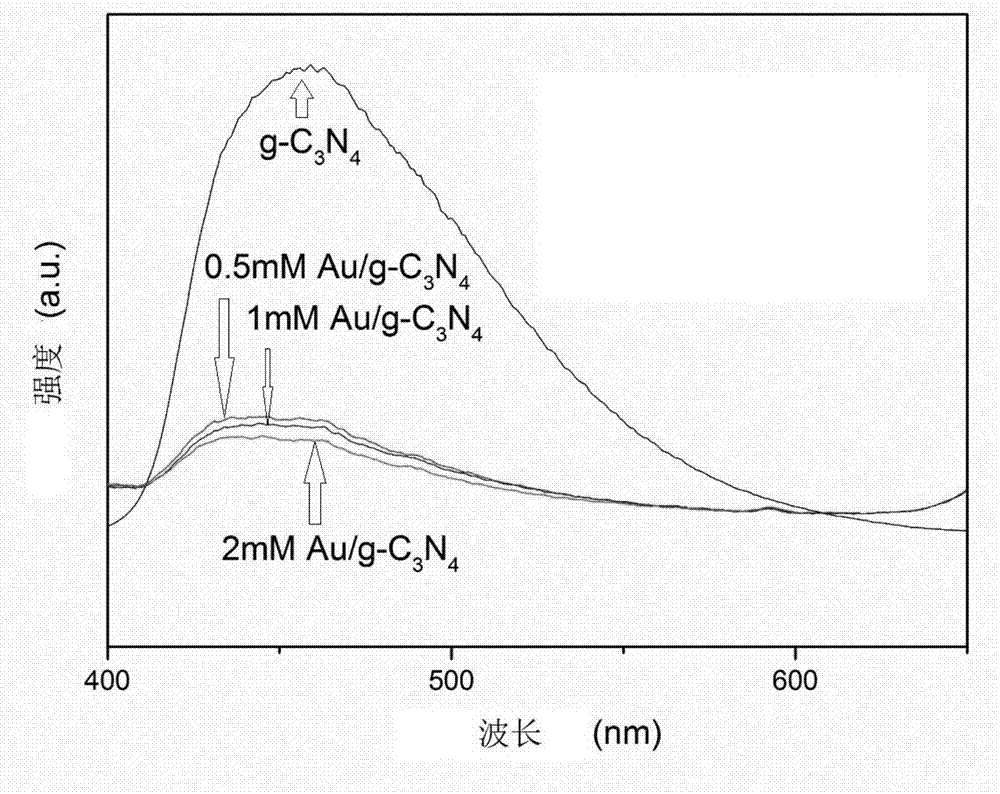

[0035] (2) By mixing a certain amount of lignin with calcined carbon nitride powder and adding chloroaurate, under the condition of heating in a water bath, control the pH of the solution, the heating temperature and time, and obtain it by X-ray energy spectrometer Optimal carbon nitride deposited by precious metal nanogold;

[0036] (3) The carbon nitride composite material deposited by the noble metal was centrifuged at high speed, dried under vacuum conditions, and placed in a muffle furn...

Embodiment 1

[0056] This implementation case demonstrates a method for preparing carbon nitride modified by lignin reduction nano-gold particles for efficient treatment of organic pollution according to the following steps:

[0057] Step 1: Preparation of high temperature calcined carbon nitride powder

[0058] In one embodiment, this step can be specifically performed as follows: Weigh 10 mg of urea into a 15 ml alumina crucible, heat up at 2°C / min, calcinate at 550°C for 2 hours, and anneal at 3-5°C to treat the powder.

[0059] Step 2: Reduction of gold nanoparticles by heating in a water bath

[0060] In one embodiment, this step can be specifically performed as follows: Weigh 100 mg of lignin and mix it with 500 mg of carbon nitride powder, prepare 50 ml of 20 mM hydrochloric acid solution and add chloroaurate (2 mM), under the action of magnetic stirring, Heat in a water bath at 80°C for 12h, centrifuge at 4000r / min for 15min, and vacuum dry at 60°C for 12h.

[0061] Step 3: Second...

Embodiment 2

[0065] This implementation case demonstrates a method for preparing carbon nitride modified by lignin reduction nano-gold particles for efficient treatment of organic pollution according to the following steps:

[0066] Step 1: Preparation of high temperature calcined carbon nitride powder

[0067] In one embodiment, this step can be specifically performed as follows: Weigh 10 mg of urea into a 15 ml alumina crucible, heat up at 2°C / min, calcinate at 550°C for 2 hours, and anneal at 3-5°C to treat the powder.

[0068] Step 2: Reduction of gold nanoparticles by heating in a water bath

[0069] In one embodiment, this step can be specifically performed as follows: Weigh 200 mg of lignin and mix it with 1 g of carbon nitride powder, prepare 50 ml of 20 mM hydrochloric acid solution and add chloroaurate (4 mM), under the action of magnetic stirring, Heat in a water bath at 80°C for 12h, centrifuge at 4000r / min for 15min, and vacuum dry at 60°C for 12h.

[0070] Step 3: Secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com