Monovalent salt mixed solution nanofiltration separation method

A solid-liquid separation and solution technology, applied in the field of membrane engineering, can solve the problems that the effluent water quality cannot meet the reuse requirements, and achieve the effects of excellent water quality, stable operation, and low floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

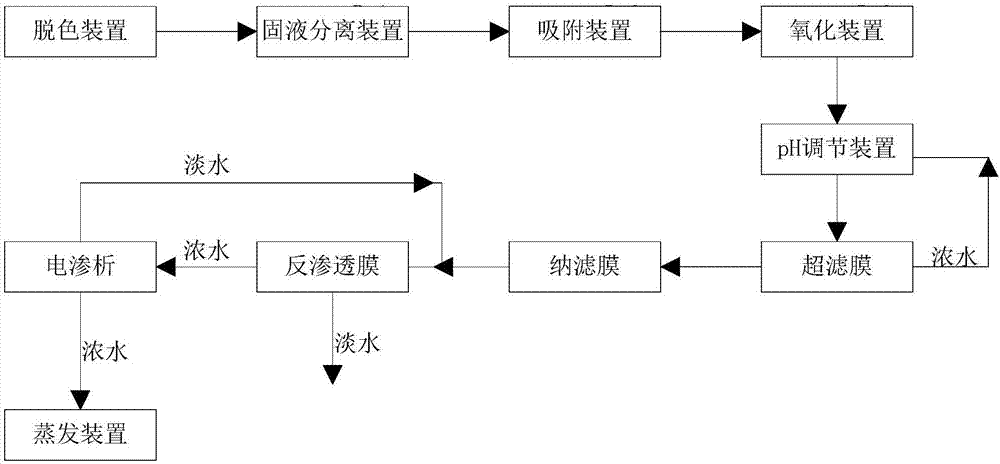

Method used

Image

Examples

Embodiment 1

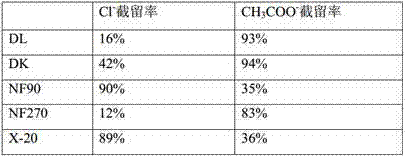

[0072] Example 1 Wastewater nanofiltration simulation test

[0073] The laboratory configures 1000mg / L CH 3 COONa and 1000mg / L NaCl mixed solution. Four nanofiltration membranes are used: GE's DL nanofiltration membrane, GE's DK nanofiltration membrane, Dow's NF90 nanofiltration membrane, Dow's NF270 nanofiltration membrane and a reverse osmosis membrane TRISEP X-20 reverse osmosis membrane. Permeable membrane for separation experiments. The separation process temperature is 25°C and the operating pressure is 1.5 MPa.

[0074] The above 5 kinds of nanofiltration membranes were used to carry out the separation test under the condition of pH 10.5, and the obtained rejection rates are shown in the following table:

[0075]

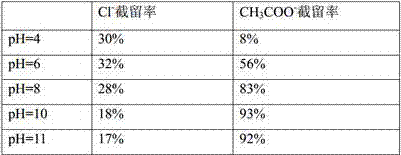

[0076] Under different pH conditions, the effect of nanofiltration membrane DL on Cl - and CH 3 COO - The retention rate is shown in the table below:

[0077]

[0078] Nanofiltration technology was used to treat the simulated pigment wastewater f...

Embodiment 2

[0079] Example 2 Treatment of Pigment Production Wastewater

[0080]Add acid to the production wastewater of Yanhuang 14 to adjust the pH to 4~6, carry out aeration, control the dissolved oxygen to 2~3mg / L, and send it to the iron-carbon micro-electrolysis tank for decolorization treatment. The iron-carbon micro-electrolysis filler is made of iron filings , Powdered activated carbon, the weight ratio of iron filings and powdered activated carbon is 5.6:1, COD 3705mg / L after treatment, the decolorized wastewater enters the aerobic pool for biochemical treatment, and then sent to the sedimentation tank for solid-liquid separation by sedimentation method, and then sent to microfiltration membrane for further filtration. After the water produced by the microfiltration membrane is sequentially treated by activated carbon adsorption and ozone oxidation, the wastewater COD is 430mg / L, and after adjusting the pH to 10.0, it is sent to the ultrafiltration membrane for deep filtration. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com